Nitrogen-mediated three-stage steady-state protection infant complementary food nutrition bag and preparation method thereof

A technology for infants and nutrition packs, which can be applied to other dairy products, dairy products, milk replacers, etc., and can solve problems such as vitamin attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

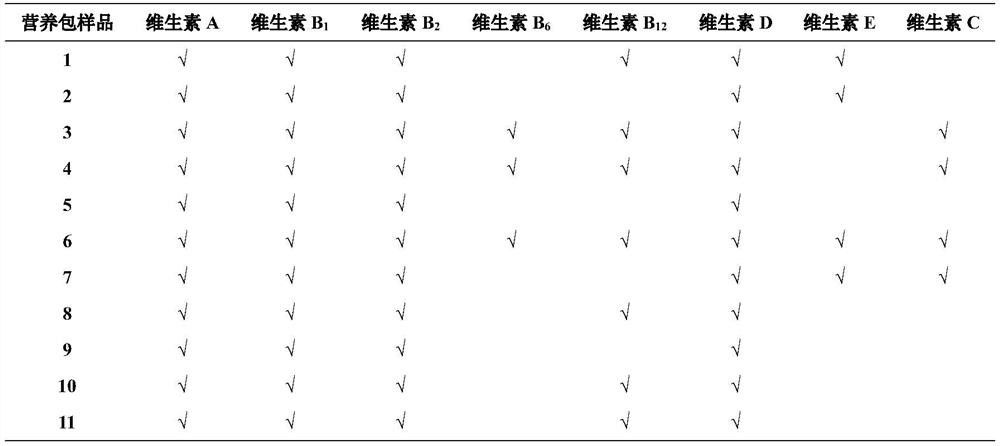

Embodiment 1

[0040] The preparation of a nitrogen-mediated three-level steady-state protection infant supplementary food nutrition package requires the following four-step preparation process in an environment with a nitrogen purity of 99.90%, a nitrogen flow rate of 800L / h, and a nitrogen flow pressure of 0.6MPa:

[0041] (1) Vibrating sieving of the forming carrier raw materials: three kinds of forming carrier raw materials, namely instant soybean powder with a protein content ≥ 32%, whole milk powder with a protein content ≥ 23%, and maltodextrin, are carried out sequentially under the guidance of nitrogen. Carry out vibrating sieve sieving treatment successively, the mesh number of vibrating sieve is controlled at 40 mesh;

[0042] (2) Preparation of level I stabilized nutrient powder: 0.0205kg vitamin A acetate, 0.0260kg cholecalciferol, 0.0074kg cyanocobalamin, 0.0105kg folic acid, 5.000kg maltodextrin were placed under the medium of nitrogen to avoid light Mix for 12 minutes in an a...

Embodiment 2

[0046]The preparation of a nitrogen-mediated three-level steady-state protection infant supplementary food nutrition package requires the following four-step preparation process in an environment with a nitrogen purity of 99.99%, a nitrogen flow rate of 200L / h, and a nitrogen pressure of 0.4MPa:

[0047] (1) Vibrating sieving of the forming carrier raw materials: three kinds of forming carrier raw materials, namely instant soybean powder with a protein content ≥ 32%, whole milk powder with a protein content ≥ 23%, and maltodextrin, are carried out sequentially under the guidance of nitrogen. Carry out vibrating sieve sieving treatment successively, the mesh number of vibrating sieve is controlled at 60 mesh;

[0048] (2) Preparation of level I stabilized nutrient powder: 0.0287kg vitamin A acetate, 0.0160kg cholecalciferol, 0.0108kg cyanocobalamin, 0.0150kg folic acid, 6.500kg maltodextrin were placed under nitrogen media and protected from light Mix for 15 minutes in an airti...

Embodiment 3

[0052] The preparation of a nitrogen-mediated three-level steady-state protection nutritional supplement package for infants and young children requires the following four-step preparation process in an environment where the nitrogen purity is 99.00%, the nitrogen flow rate is 1500L / h, and the nitrogen flow pressure is 0.9MPa:

[0053] (1) Vibrating sieving of forming carrier raw materials: three kinds of forming carrier raw materials, instant soybean powder with protein content ≥ 32%, whole milk powder with protein content ≥ 23%, and maltodextrin, are mediated by nitrogen in sequence. Next, carry out the vibrating sieve sieving treatment successively, and the mesh number of the vibrating sieve is controlled at 80 mesh;

[0054] (2) Preparation of level I stabilized nutrient powder: 0.0369kg vitamin A acetate, 0.036kg cholecalciferol, 0.0040kg cyanocobalamin, 0.0060kg folic acid, 8.00kg maltodextrin were placed under the medium of nitrogen to avoid light Mix for 10 minutes in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com