Treatment equipment for PDC drill bit out of well

A technology for processing equipment and drill bits, which is applied in the field of oil drilling, can solve the problems of large manpower and cost, and achieve the effects of reducing the difficulty of stripping, improving the ability of dissolving and dispersing, and reducing manpower consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

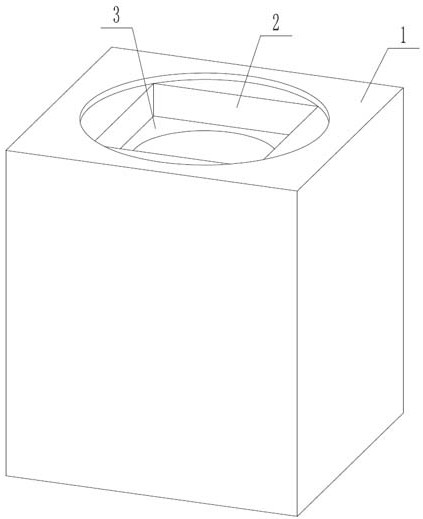

[0032] Such as figure 1 and figure 2 The shown processing equipment for the PDC bit that goes out of the well is suitable for the automatic processing of the PDC bit that has bagging phenomenon after going out of the well. Driven to rotate, the turntable 2 includes a square step surface 3, the step surface 3 is used to carry the drill bit loader; also includes a processing bucket 4 located below the turntable 2, and moves between the treatment barrel 4 and the turntable 2 Seal fit, and the processing barrel 4 is fixed with the box body 1, and the bottom of the processing barrel 4 is provided with a discharge valve 5; the processing barrel 4 is used to accommodate the processing agent. The turntable 2 includes a square diameter portion 201 and a circular diameter portion 202 distributed up and down, the square diameter portion 201 matches the square step surface 3, and the inner diameter of the circular diameter portion 202 is the same as that of the processing barrel. The i...

Embodiment 2

[0036] Such as figure 1 and figure 2 In the shown processing equipment for PDC drill bits, on the basis of Embodiment 1, the inner wall of the box 1 is provided with an annular track 7, and the turntable 2 is slidably fitted in the annular track 7; the drive assembly includes The ring rack 8 fixedly sleeved on the outside of the turntable 2, the gear 9 meshing with the ring rack 8, and the motor 10 for driving the gear 9 to rotate; a plurality of gears 9 are evenly distributed in the ring outside the ring rack 8 , each gear 9 is meshed with the ring rack 8; one of the gears 9 is connected to the output end of the motor 10, and the other gears 9 are connected to the inner wall of the box 1 through the connecting shaft 11, and the gears 9 are rotatably fitted on the corresponding connecting shaft 11 on.

Embodiment 3

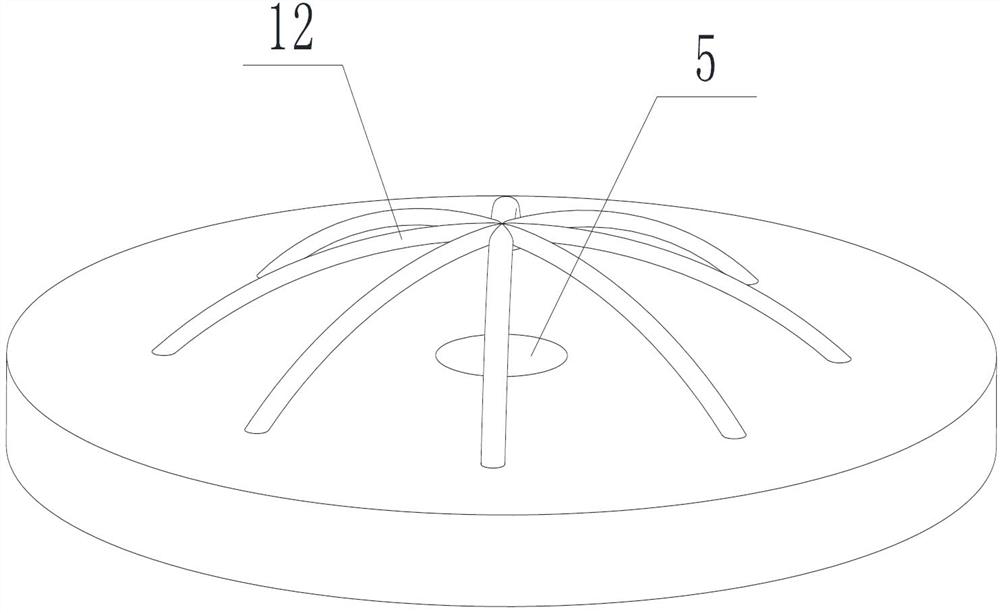

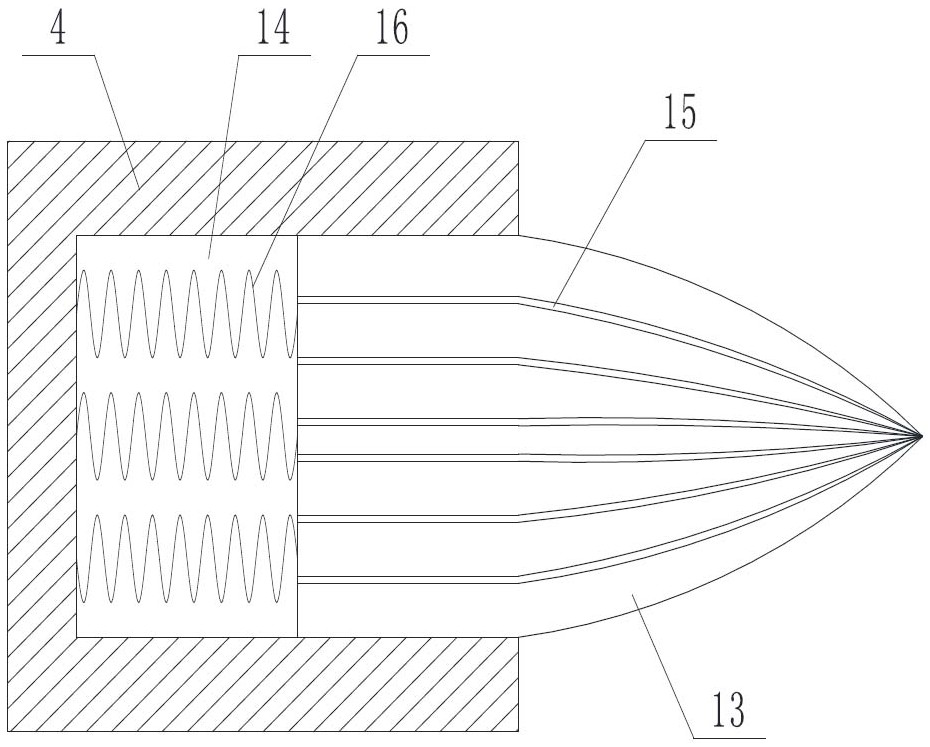

[0038] Such as figure 1 and figure 2 The shown processing equipment for the PDC drill bit in the well, on the basis of any of the above-mentioned embodiments, the inner bottom surface of the processing barrel 4 is set as image 3 The umbrella-shaped skeleton 12 shown, the umbrella-shaped skeleton 12 is coaxial with the processing barrel 4, and the height of the umbrella-shaped skeleton 12 gradually decreases from the center to the surroundings; the inner side wall of the processing barrel 4 is provided with a number of scrapers 13; A plurality of ring-shaped and evenly distributed water pumps 17 are arranged in the box body 1, and the upper water end and the water outlet end of the water pump 17 are respectively connected to the upper water channel 18 and the drainage channel 19, and the upper water channel 18 is connected to the bottom of the side wall of the processing barrel 4. Said drainage channel 19 communicates with the top of the side wall of the treatment barrel 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com