A horizontal grinding device

A grinding device, horizontal technology, applied in the direction of grinding machines, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc. The grinding effect of the grinding body, the single movement law and other problems can achieve the effect of strengthening treatment, ingenious design, and small impact on normal operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

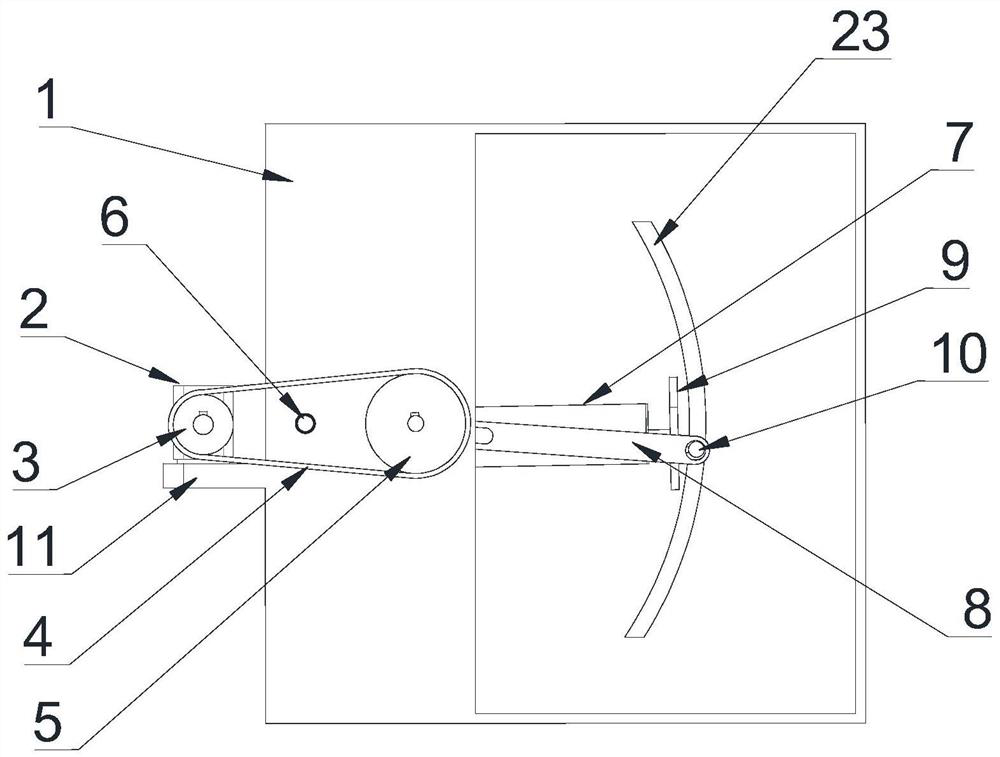

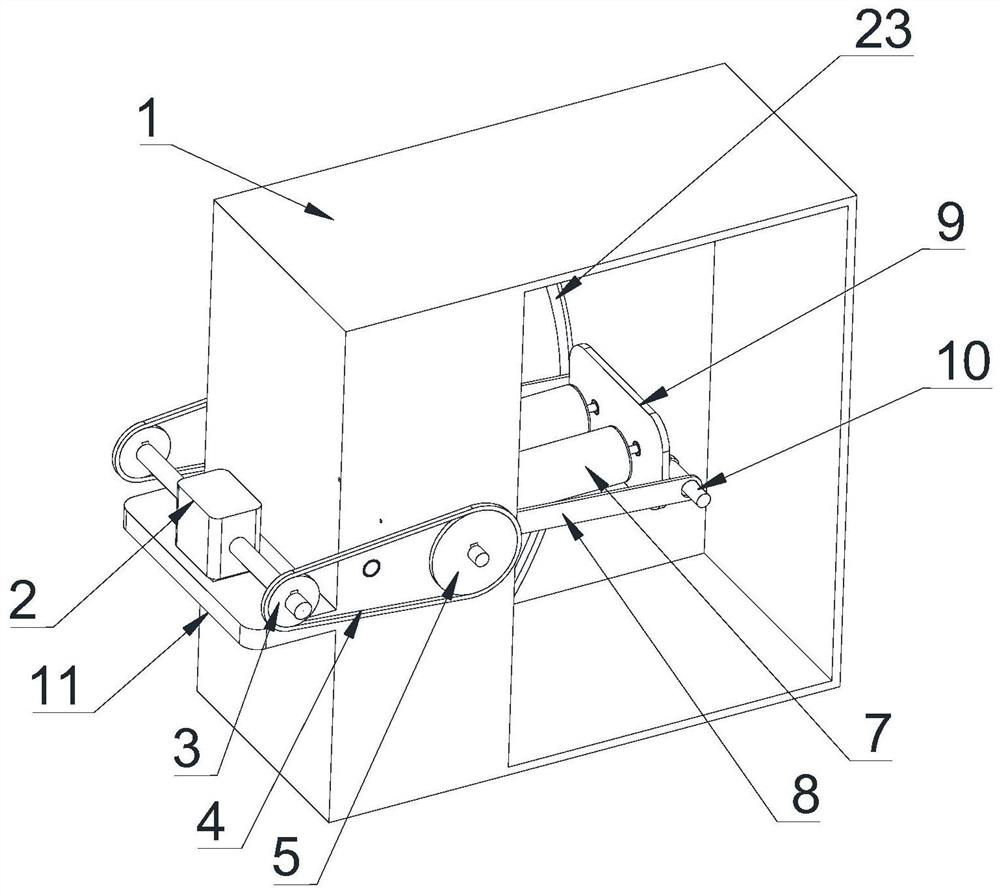

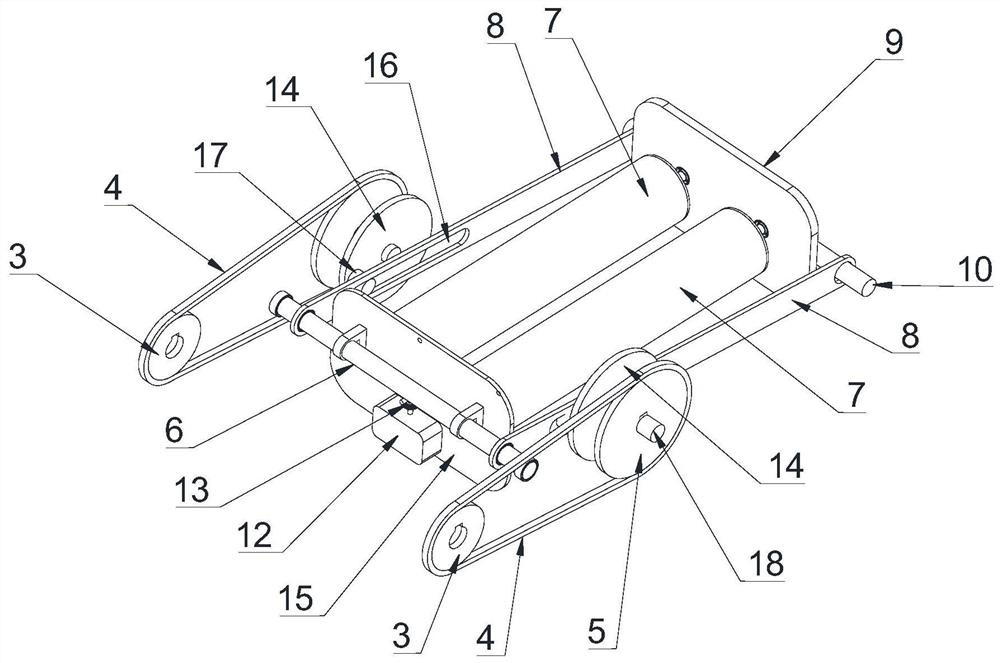

[0032] see Figure 1-Figure 8 , The horizontal grinding device of this embodiment includes a drum 7, a grinding drive mechanism that drives the drum 7 to rotate around the axis, a swing mechanism, and a scraper mechanism. in:

[0033] see Figure 1-Figure 4 , the swing mechanism includes a swing frame and a swing drive mechanism that drives the swing frame to swing, the cylinder 7 and the grinding drive mechanism are all arranged on the swing frame; the swing frame includes a fixed shaft 6 and a swing bracket, and the swing One end of the bracket is rotatably connected to the fixed shaft 6, the other end of the swing bracket is extended along the axis direction of the drum 7, the drum 7 is arranged on the swing bracket along the length direction, and the swing drive mechanism drives the swing bracket A rotational movement takes place about said fixed axis 6 .

[0034] see Figure 1-Figure 4 , the swing bracket includes a first connecting plate 15, a second connecting plate...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is that the swing driving mechanism includes a cam and a rotation driving mechanism for driving the cam to rotate, and the cam is arranged under the power side plate 8 . In this way, when the rotation driving mechanism drives the cam to rotate, the diameter of the cam changes to realize jacking up and down of the power side plate 8, thereby realizing the swing of the whole swing bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com