Puzzle type hard floor with customized patterns and preparation method and application of hard floor

A technology for customizing patterns and floors, which is applied in the field of building decoration materials, can solve the problems of single pattern and texture, reduce the service life of the floor, and the bonding of the sheet floor is not firm, so as to achieve the effect of firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

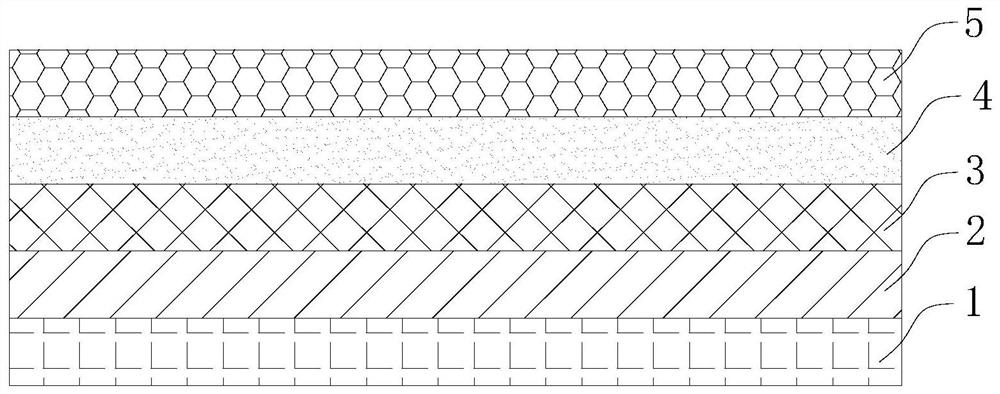

[0063] Such as image 3 , Figure 4 and Figure 5 Shown, a kind of jigsaw type custom pattern hard floor, comprises base material layer 1, pattern layer 2, UV adhesive layer 3, PVC wear-resistant layer 4 and UV coating wear-resistant layer 5; Described base material layer 1 is made of It consists of a hard sheet, the pattern layer 2 is printed on the substrate layer, the PVC wear-resistant layer 4 is bonded on the substrate layer 1 printed with the pattern layer 2 through the UV adhesive layer 3, and the UV coating is resistant to The abrasive layer 5 is coated on the PVC wear-resistant layer 4 . Described substrate layer 1 is stone crystal floor base material; Described stone crystal floor base material is the stone crystal floor base material that is covered with white PVC film and no wear-resistant layer (if the stone crystal floor base material itself has wear-resistant layer, it will It will affect the spraying of the pattern layer); the PVC wear-resistant layer is a P...

Embodiment 2

[0065] As shown in Example 1, the other structures of the hard floor with a jigsaw pattern and customized pattern are the same as in Example 1, wherein the PVC wear-resistant layer is a PVC translucent material layer.

Embodiment 3

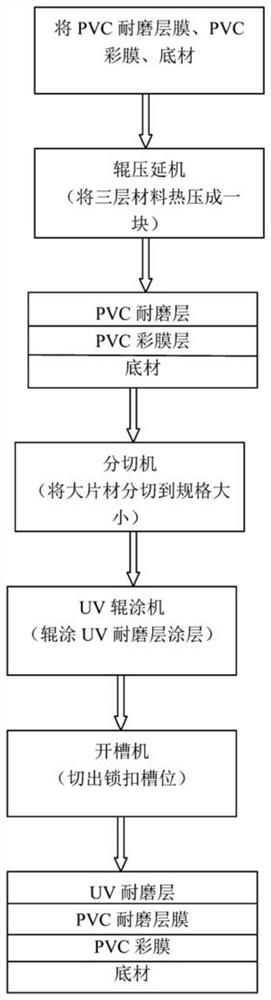

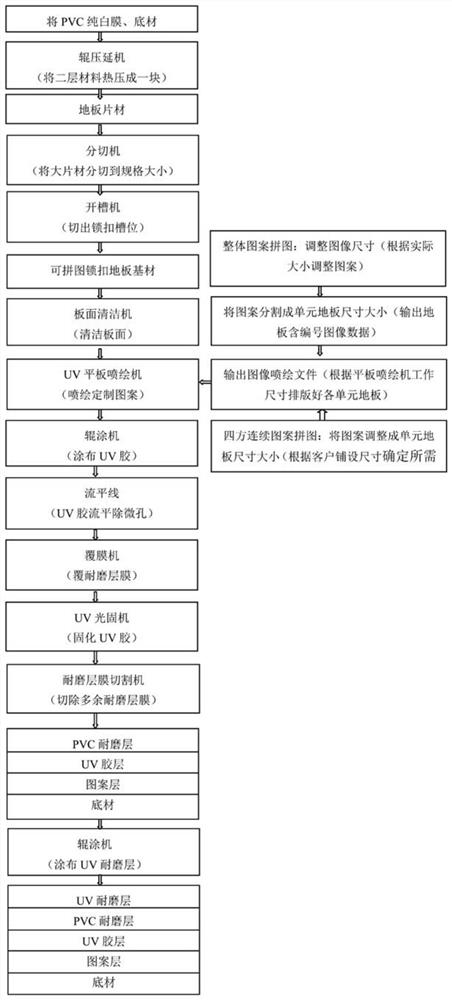

[0067] Such as figure 2 Shown, a kind of preparation method of the hard floor of puzzle type customized pattern as shown in embodiment 1, comprises the following steps:

[0068] (1) Floor sheet production: The PVC pure white film is hot-pressed into a whole floor sheet through a roller calender and a substrate.

[0069] (2) Slitting the floor sheet in step (1) into required sizes by a slitting machine.

[0070] (3) Cut the floor sheet obtained in step (2) out of the locking slots by a slotting machine to make a jigsaw-style custom-designed locking floor substrate, and use a board surface cleaning machine to clean the board surface. Clean and free of impurities and chemical additives, otherwise it will affect the adhesion between ink and board.

[0071] (4) the lock floor base material in the step (3) is passed through the UV flat-panel inkjet printer, and the customized pattern layer is spray-painted;

[0072] The specific steps are: do a good job of positioning on the UV ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com