A new water-based prochloraz formulation zw and its processing and application

A technology of prochloraz and a new formulation, applied in the field of pesticide production and processing, can solve the problems of low content of active ingredients, adverse environmental impact, poor lasting effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The processing method of the new prochloraz formulation ZW in this example is as follows: first, 10% prochloraz CS is processed by the interfacial polymerization method, and 20% prochloraz EW is processed by the conventional method, and the two are uniformly mixed according to the mass ratio of 4:6 to obtain 16 % Prochloraz ZW.

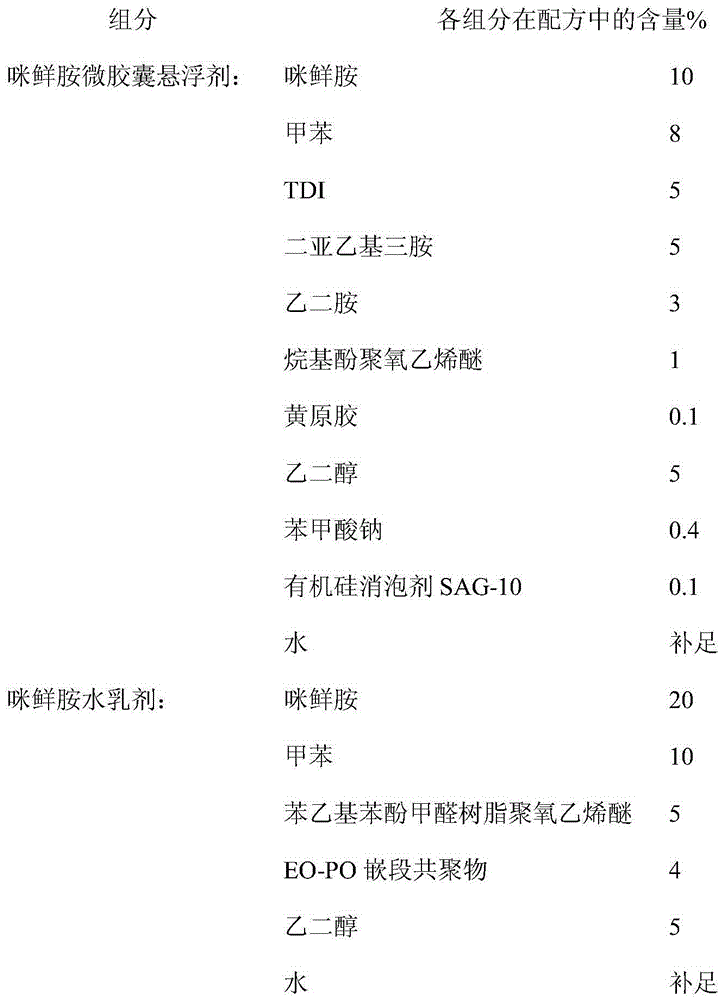

[0044] Table 1: Mixture of prochloraz microcapsule suspension processed by interfacial polymerization and aqueous emulsion processed by conventional method

[0045]

[0046] The prepared 16% prochloraz new dosage form ZW can reach the following technical indicators: suspension rate ≥ 93%; emulsion stability is qualified; cyst formation rate ≥ 91%; automatic dispersibility ≥ 90%; pH value is qualified; The indicators are qualified; the indicators of thermal storage are qualified; the indicators of freeze-thaw stability are qualified.

Embodiment 2

[0048] The processing method of the new prochloraz formulation ZW in this example is as follows: first, 20% prochloraz CS is processed by the interfacial polymerization method, and 20% prochloraz EW is processed by the conventional method, and the two are uniformly mixed according to the mass ratio of 2:8 to obtain 20% prochloraz % Prochloraz ZW.

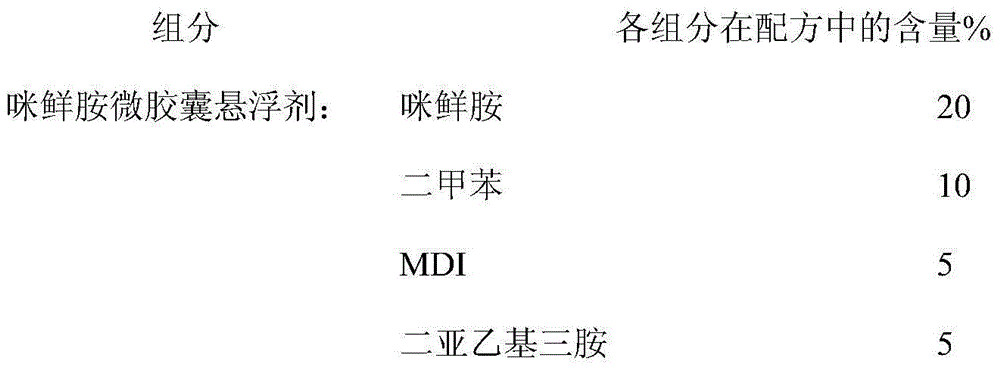

[0049] Table 2: Mixture of prochloraz microcapsule suspension processed by interfacial polymerization and aqueous emulsion processed by conventional method

[0050]

[0051]

[0052] The prepared 20% prochloraz new formulation ZW can meet the following technical indicators: suspension rate ≥ 94%; emulsion stability qualified; cyst formation rate ≥ 90%; automatic dispersibility ≥ 91%; pH value qualified; The indicators are qualified; the indicators of thermal storage are qualified; the indicators of freeze-thaw stability are qualified.

Embodiment 3

[0054] The processing method of the new prochloraz formulation ZW in this example is as follows: firstly, the prochloraz CS is processed by the interfacial polymerization method, and the prochloraz oil phase (including prochloraz, toluene, and emulsifier) is added after the CS is formed into capsules and solidified. See the table below, stir thoroughly to obtain 35% prochloraz ZW.

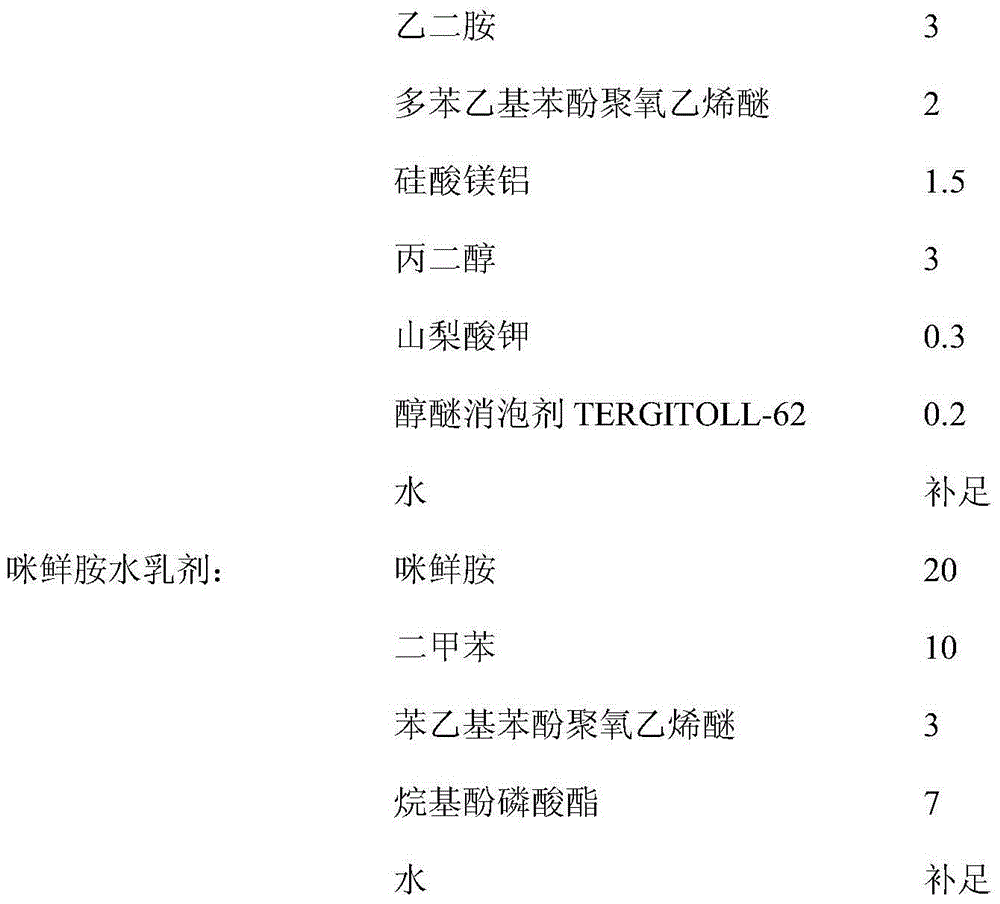

[0055] Table 3: 35% prochloraz ZW formulation

[0056]

[0057]

[0058] The prepared 35% prochloraz new dosage form can meet the following technical indicators: suspension rate ≥ 94%; emulsion stability qualified; cyst formation rate ≥ 90%; automatic dispersibility ≥ 91%; pH value qualified; The indicators are qualified; the indicators of heat storage are qualified; the indicators of freeze-thaw stability are qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com