A kind of forming equipment of graphene RFID electronic tag antenna

A technology of electronic labels and molding equipment, which is applied to general parts of printing machinery, gravure rotary printing machines, printing, etc., and can solve problems such as insufficient antenna density, poor product consistency, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

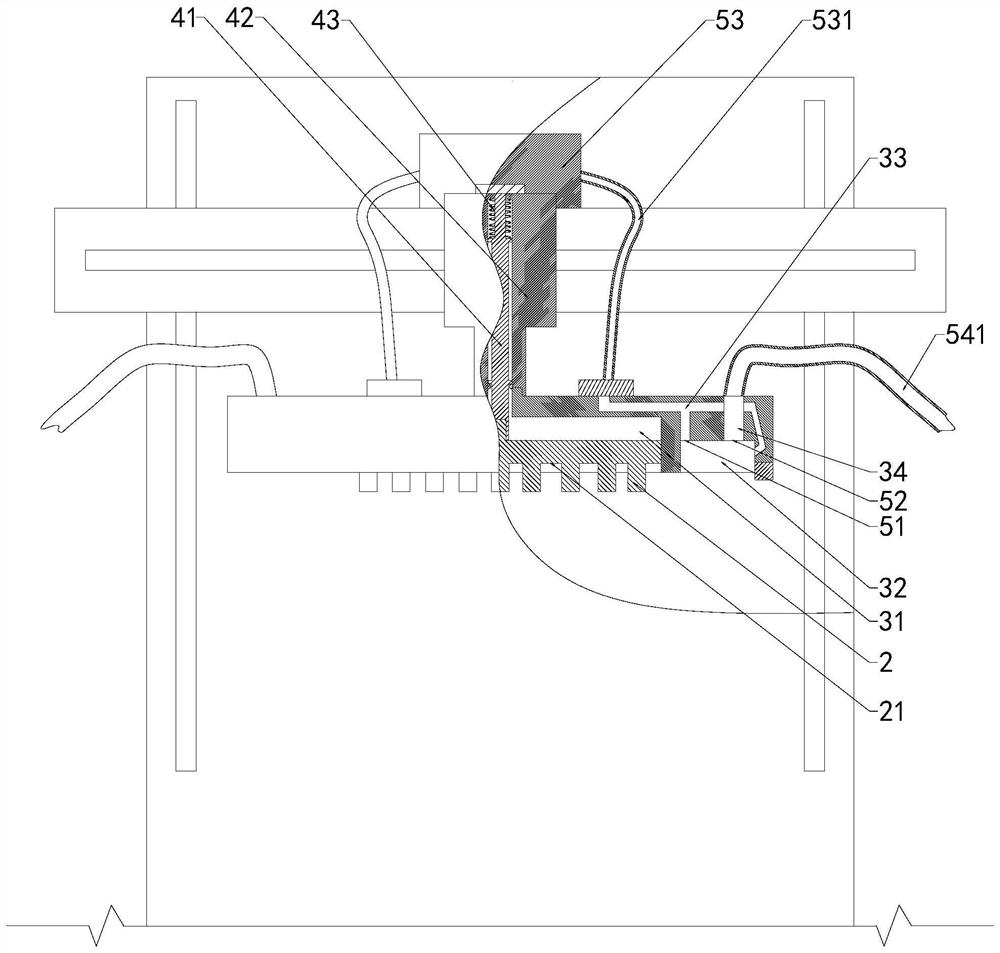

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific embodiments of the present invention will now be described with reference to the accompanying drawings. The same reference numerals in each figure represent components with the same structure or similar structure but the same function.

[0037] Many specific details are set forth in the following description to facilitate a full understanding of the present application. However, the present application can also be implemented in other ways different from those described herein. Therefore, the protection scope of the present application is not limited by the specific details disclosed below. Example limitations.

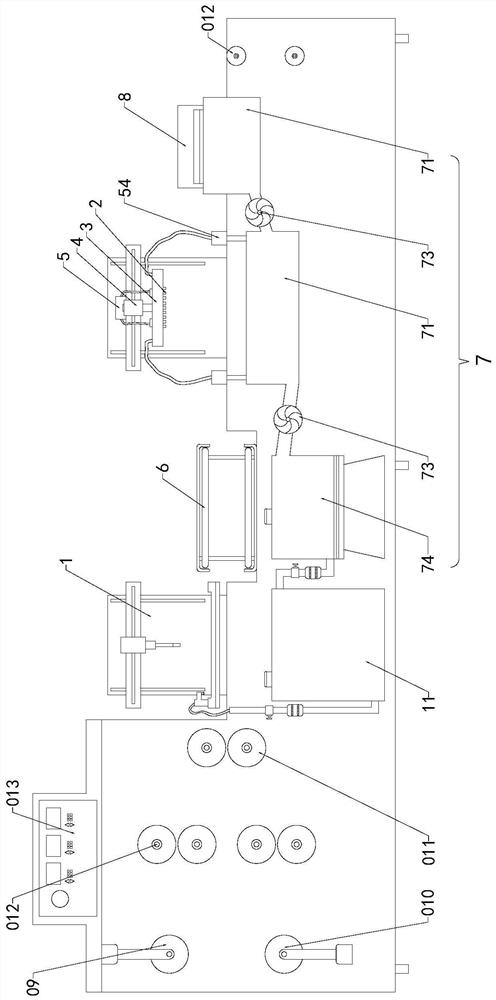

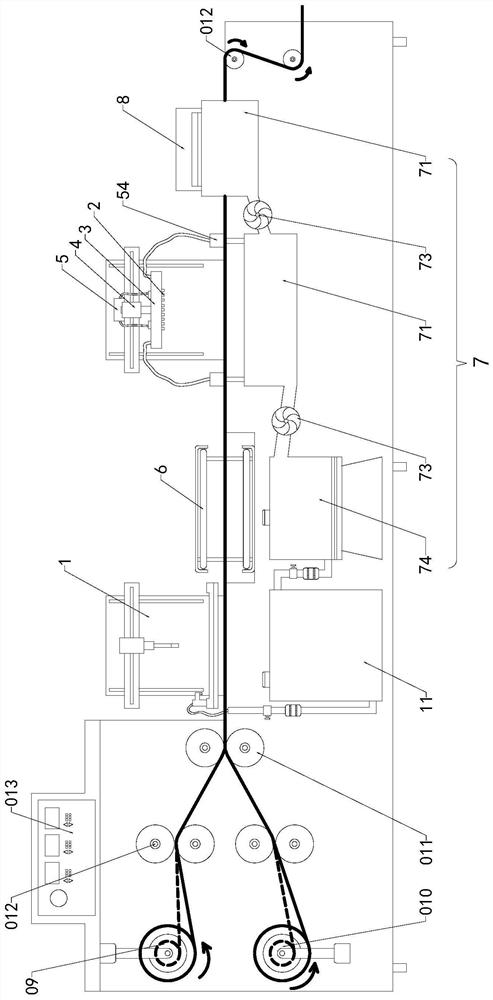

[0038] refer to Figure 1 to Figure 4 , figure 1 It is a kind of schematic embodiment of the molding equipment of a graphene RFID electronic tag antenna. The electronic tag antenna is made of graphene conductive paste as a raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com