A spiral tower conveyor

A conveyor and spiral tower technology, which is applied in the field of conveying equipment, can solve the problems of large impact load, deformation fracture and impact movement of the network chain, and achieve the effect of improving the bearing capacity, prolonging the service life and compensating for the length change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] In the following description of the present invention, the orientations or positional relationships indicated by the terms "front", "rear", "left", "right", "inner", "outer", etc. are based on the orientations or positional relationships shown in the drawings , is only for the convenience of describing the present invention and simplifying the description, and does not mean that the device must have a specific orientation, and the conveyor can be arranged in a mirror image of the direction shown in the figure.

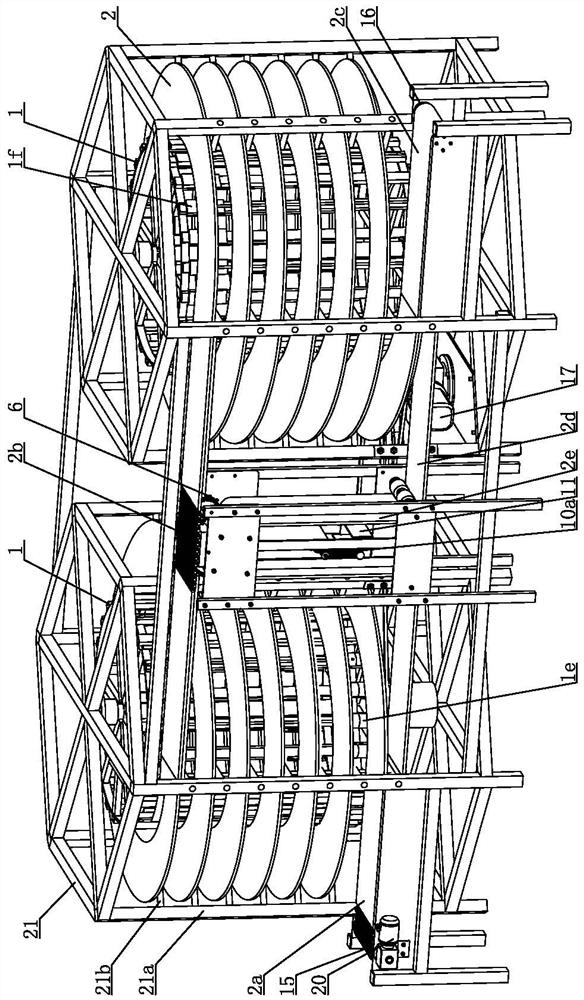

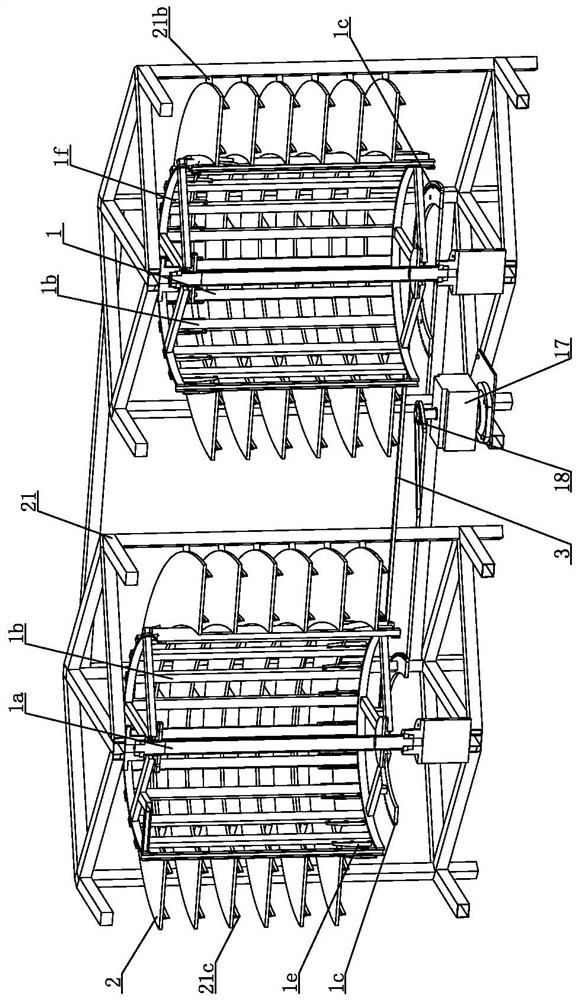

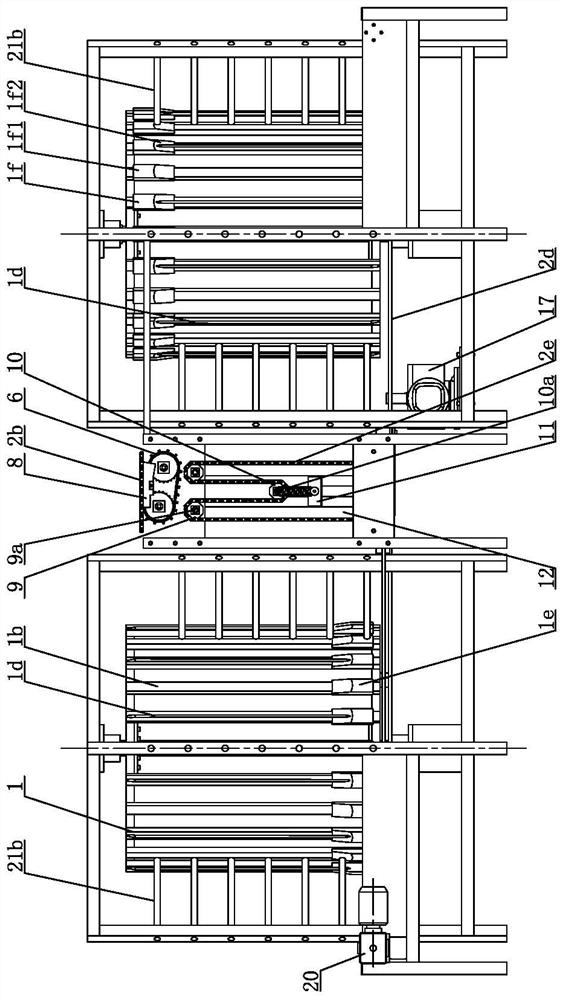

[0078] Such as Figure 1 to Figure 7 As shown, the spiral tower conveyor of the present invention includes a drum 1, and the mesh chain 2 is helically wound around the periphery of the drum 1 and rotates synchronously with the drum 1. There is a driving head 2f protruding toward the direction of the cylinder, the inner edge of the driving head 2f is in a convex arc shape, and the double or one side of the driving head 2f is provided with an arc groove matching t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com