Fuel oil and biomass particles integrated energy-saving stove

A biomass particle, energy-saving stove technology, applied in the field of energy-saving stoves, can solve the problems of taking a long time, easy to emit black smoke, unable to meet the production needs of the catering industry, etc., and achieves the effect of saving fuel, easy control of heat, and small structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

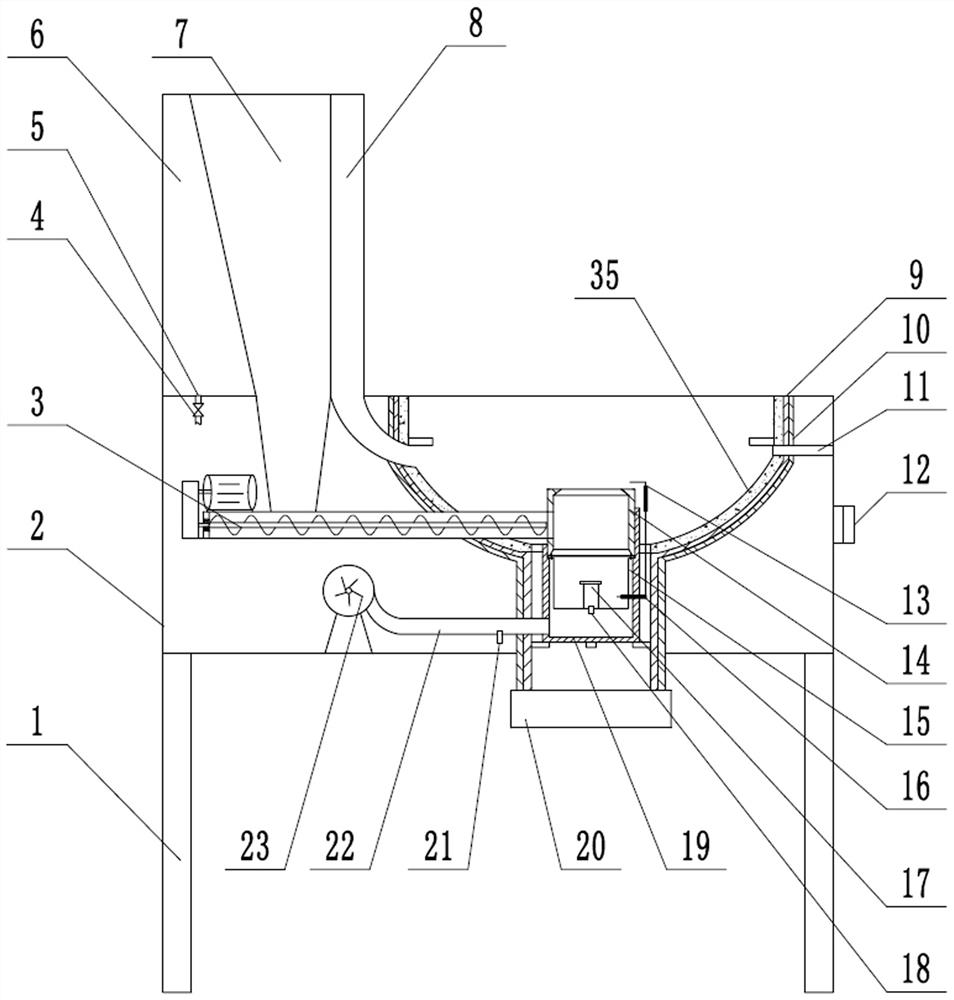

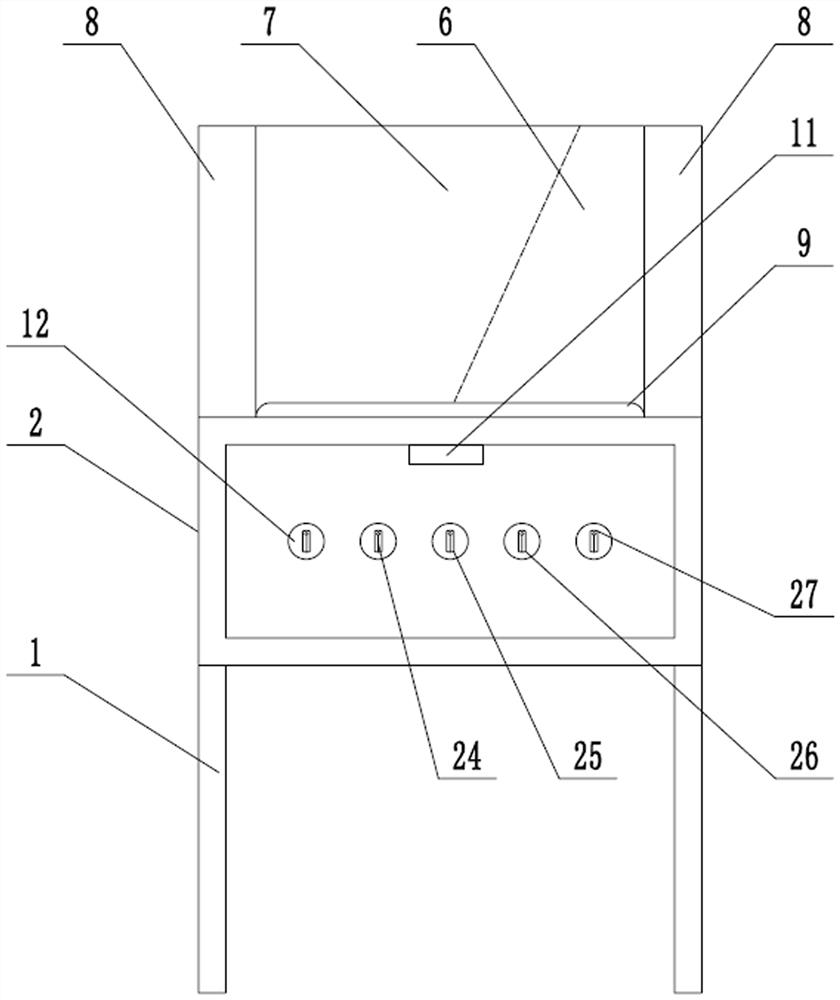

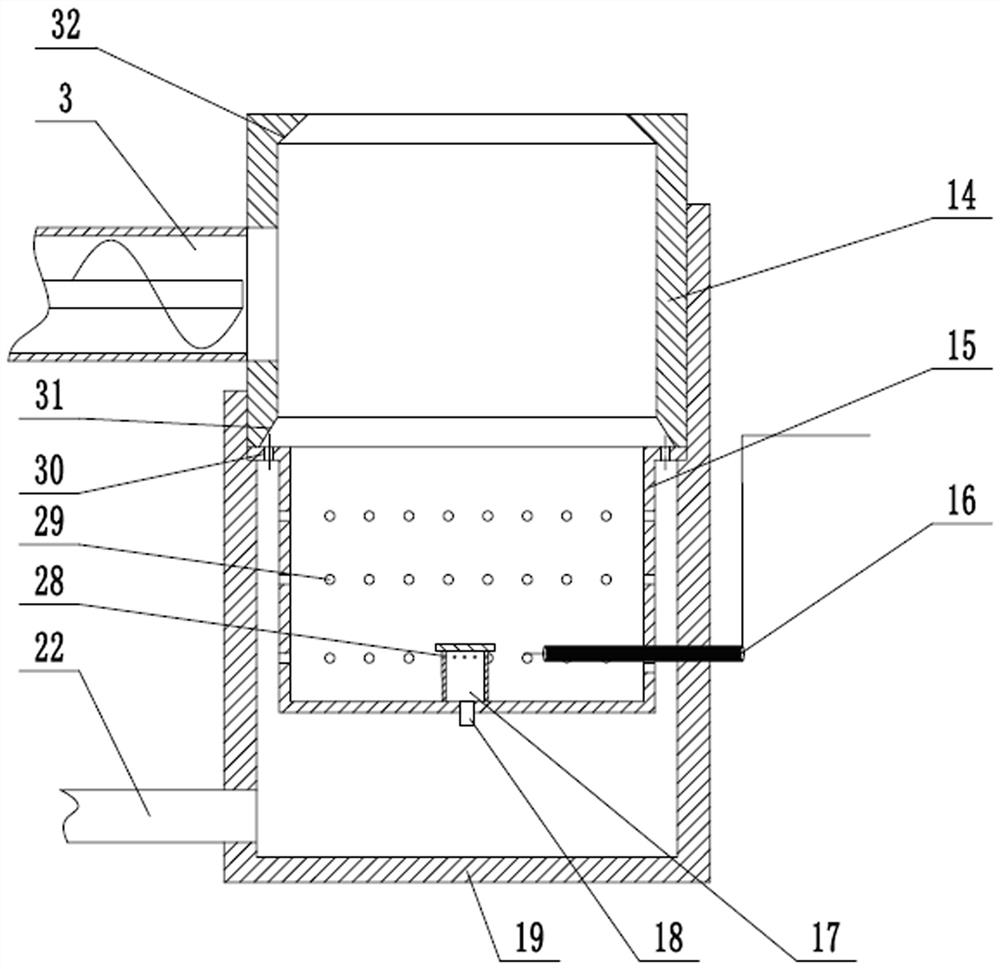

[0029] An energy-saving stove integrated with fuel oil and biomass particles, including a stove frame 1 and a stove body 9, the stove frame 1 is equipped with a stove shell 2, and the stove body 9 is installed on the stove frame 1 inside the stove shell 2 The inside of the stove body 9 is a furnace, and the rear side of the furnace is connected with a smoke exhaust channel 8, and the inner top of the furnace is used to place a pot, and the fuel tank 6 and the biomass particle box 7 are arranged on the upper rear of the furnace frame 1, The bottom of the fuel tank 6 is provided with an oil outlet 5, and an oil outlet valve 4 is installed on the oil outlet 5; the bottom of the biomass particle box 7 is provided with a discharge port, and a screw conveyor 3 is installed at the discharge port; The inner lower part of the stove body 9 is provided with a burner assembly, and the burner assembly includes an oxygen supply cylinder 19 sealed at the bottom, and the inner lower part of th...

Embodiment 2

[0037] An energy-saving stove integrated with fuel oil and biomass particles, including a stove frame 1 and a stove body 9, the stove frame 1 is equipped with a stove shell 2, and the stove body 9 is installed on the stove frame 1 inside the stove shell 2 The inside of the stove body 9 is a furnace, and the rear side of the furnace is connected with a smoke exhaust channel 8, and the inner top of the furnace is used to place a pot, and the fuel tank 6 and the biomass particle box 7 are arranged on the upper rear of the furnace frame 1, The bottom of the fuel tank 6 is provided with an oil outlet 5, and an oil outlet valve 4 is installed on the oil outlet 5; the bottom of the biomass particle box 7 is provided with a discharge port, and a screw conveyor 3 is installed at the discharge port; The inner lower part of the stove body 9 is provided with a burner assembly, and the burner assembly includes an oxygen supply cylinder 19 sealed at the bottom, and the inner lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com