A double-cam linkage high-speed clamping and tilting mechanism and its operation method

A double-cam, high-speed technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of large manual workload, decreased product qualification rate, low efficiency, etc., and achieve labor cost saving, labor cost saving, and stable rhythm. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

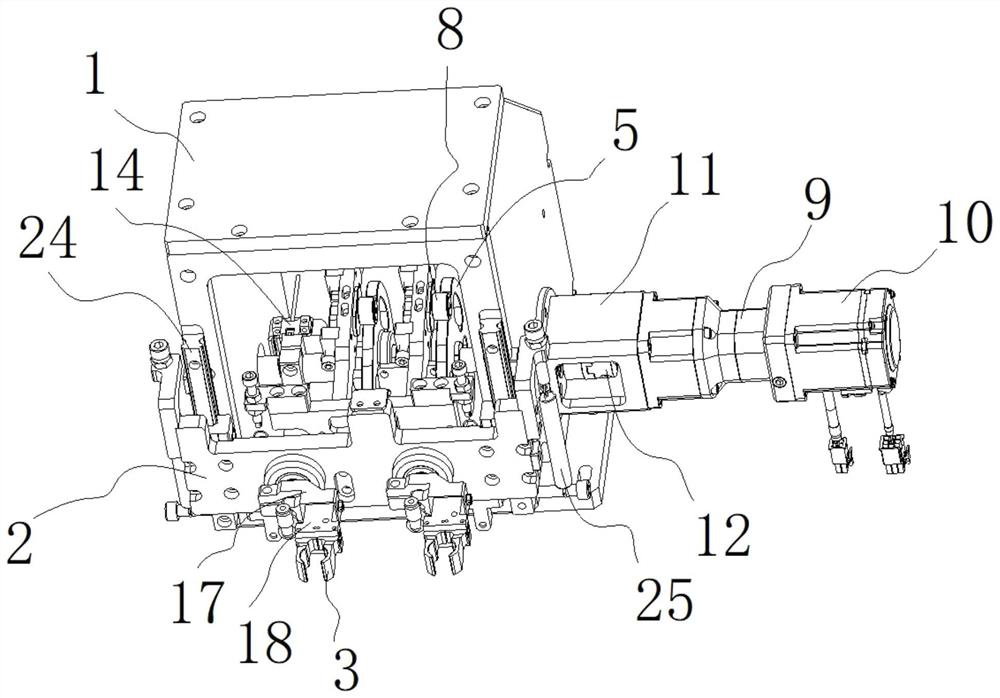

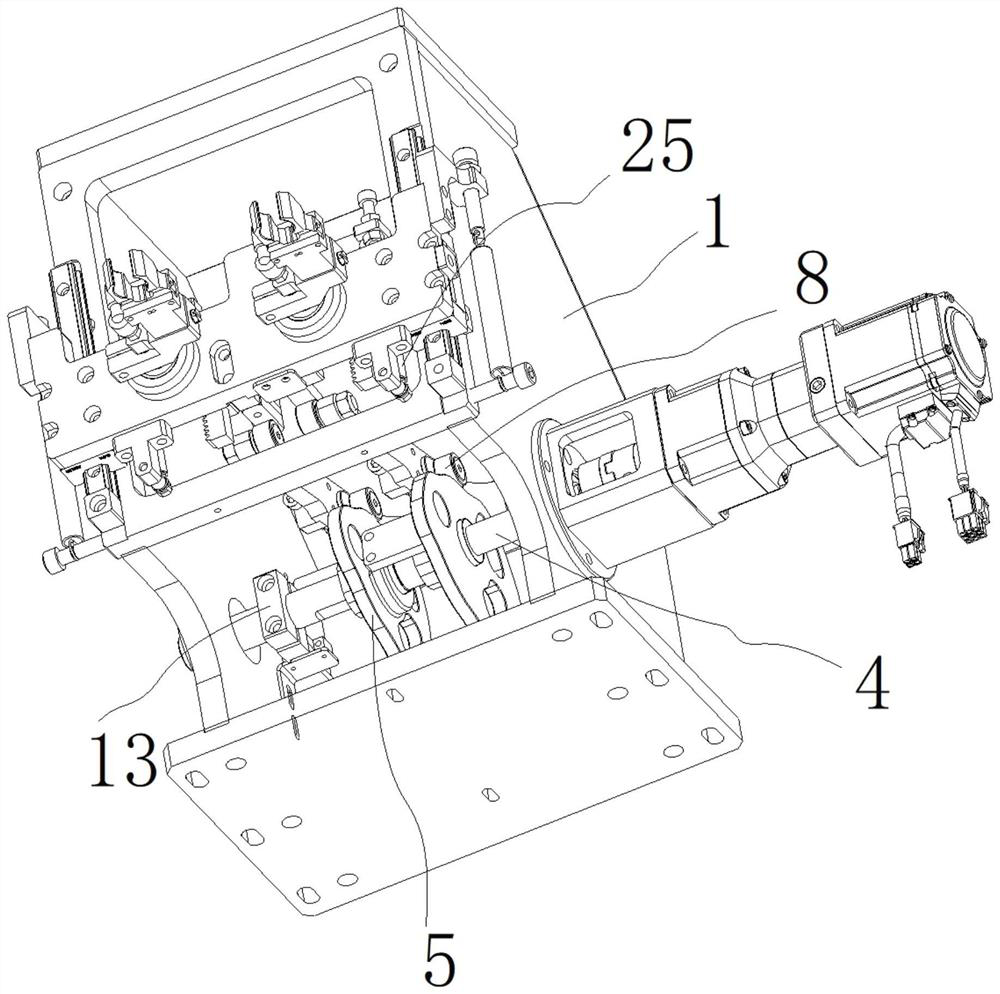

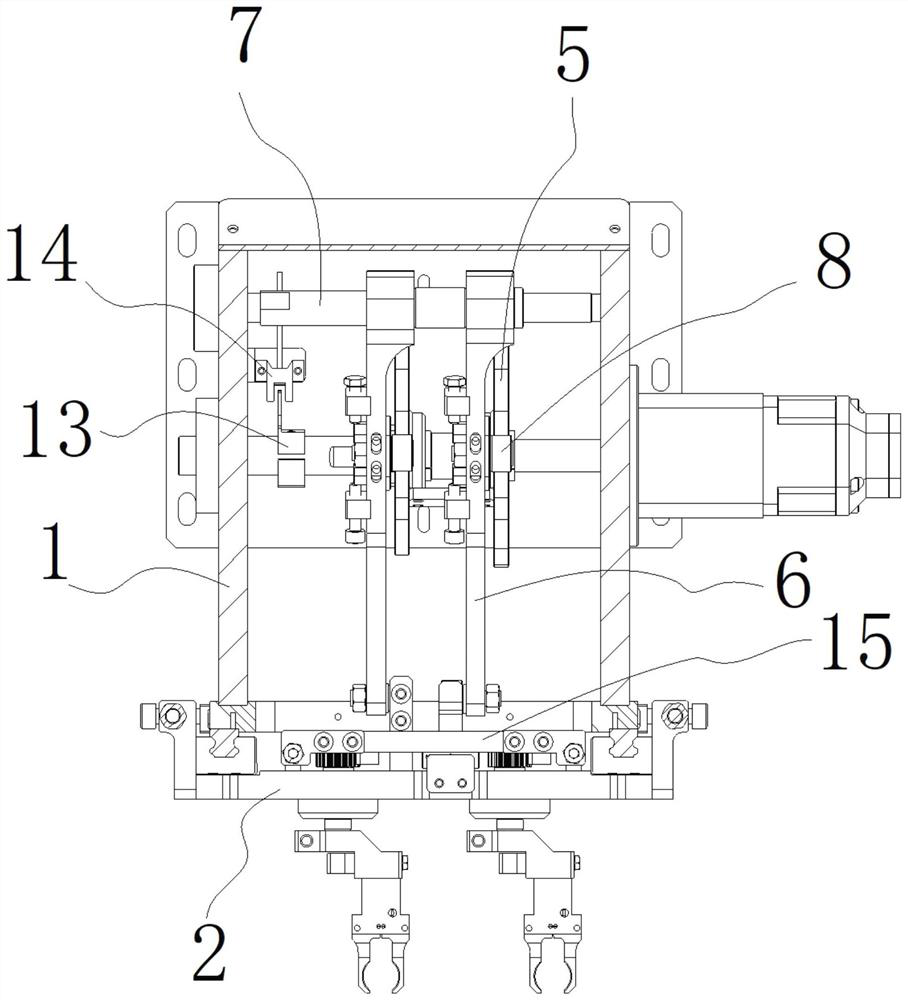

[0041] Embodiment 1: As shown in the figure, a double-cam linkage high-speed clamping and dislocation turning mechanism includes an operating frame 1, and the operating frame 1 is provided with a lifting plate 2 that can move up and down along the operating frame 1. The lifting plate 2 is provided with at least one reversible and clamping jaw 3 .

[0042] The lifting plate 2 and the clamping jaws 3 are respectively linked by a cam assembly, and the cam assembly drives the lifting plate 2 to move up and down, and the cam assembly drives the clamping jaws 3 to flip and grip.

[0043] The cam assembly includes a cam shaft 4 fixed to the operating frame 1. The cam shaft 4 is covered with a cam 5 that rotates with the cam shaft 4. The rotation of the cam 5 drives the rocker arm 6 to swing. The tail end of the rocker arm 6 The head of the rocker arm 6 swings up and down through the rotation and positioning of the rocker arm shaft 7 and the operating frame 1 .

[0044] The middle en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com