Combinable horizontal pipe type pressure flocculation device

A flocculation device and tube-type technology, which is applied in the fields of flocculation/sedimentation water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc. , good flocculation effect, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

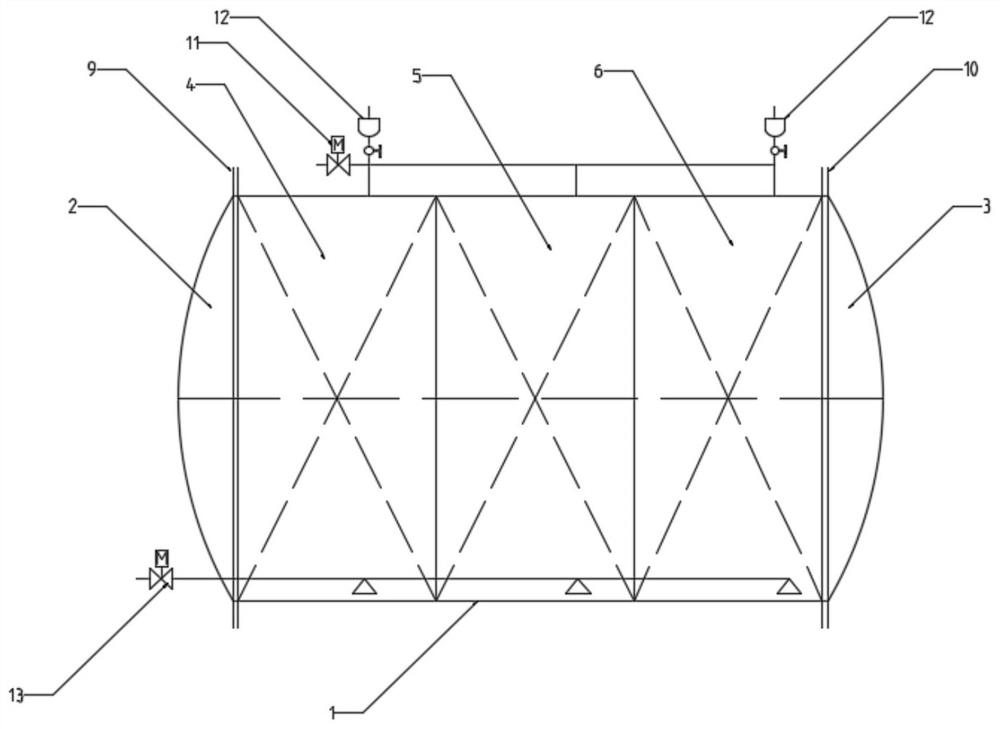

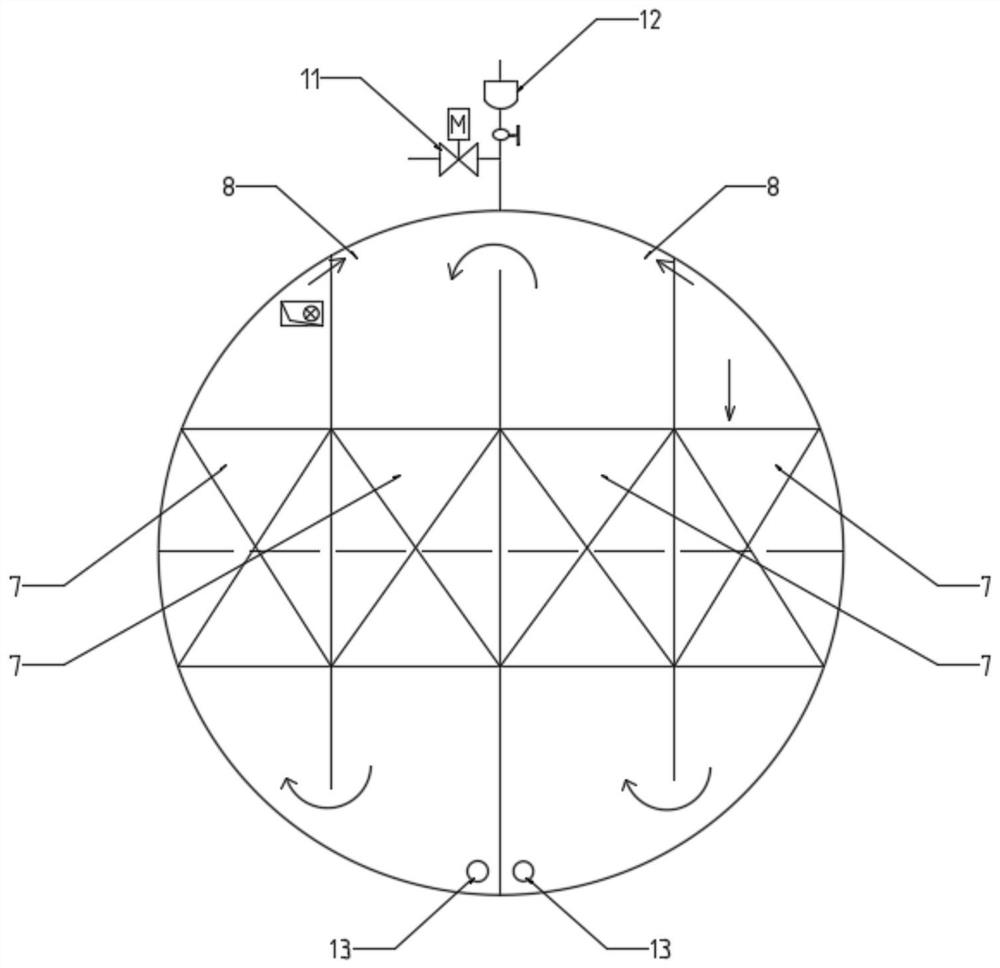

[0020] Specific embodiment 1, a combinable horizontal tubular pressure flocculation device, including the device body;

[0021] The device body includes a horizontal pipeline type pressure-bearing container body 1. The front and rear ends of the pressure-bearing container body 1 are respectively provided with a water inlet and a distribution port 2 and a water outlet 3. There are three flocculation reactions between the water inlet and distribution port 2 and the water outlet 3 Zone, including the first flocculation reaction zone 4, the second flocculation reaction zone 5 and the third flocculation reaction zone 6. The flocculation reaction zone is equipped with a micro-vortex flocculator 7. According to different flow rates and flocculation parameters, the internal flocculation The horizontal tubular pressure flocculation device suitable for the reaction zone can be combined flexibly to meet the requirements of parameters such as the appropriate flocculation time and the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com