A kind of highly active, low residue, degradable chain extender and preparation method thereof

A technology of chain extender and degradable resin, applied in the field of high activity, degradable chain extender and its preparation, low residue field, can solve the problems of difficult to achieve grafting rate, high monomer residue, difficulty in feeding, etc., to achieve broad application Prospect and industrial value, high epoxy content, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

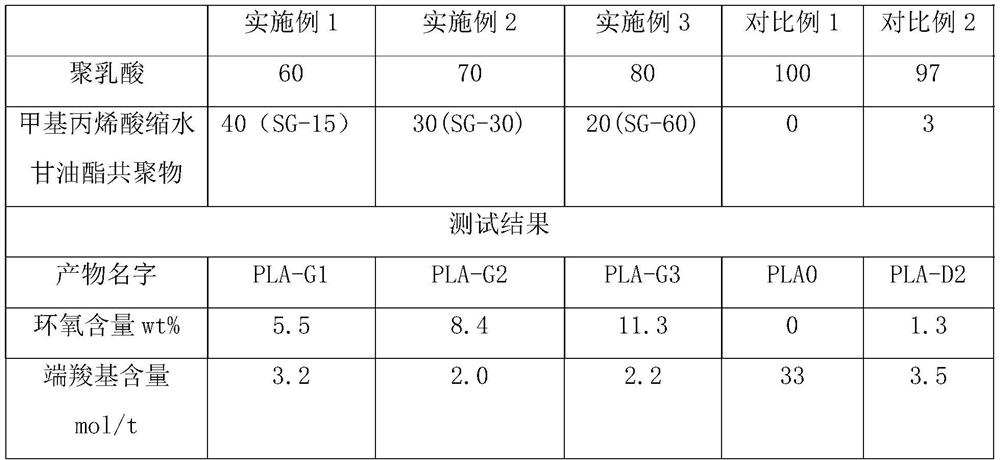

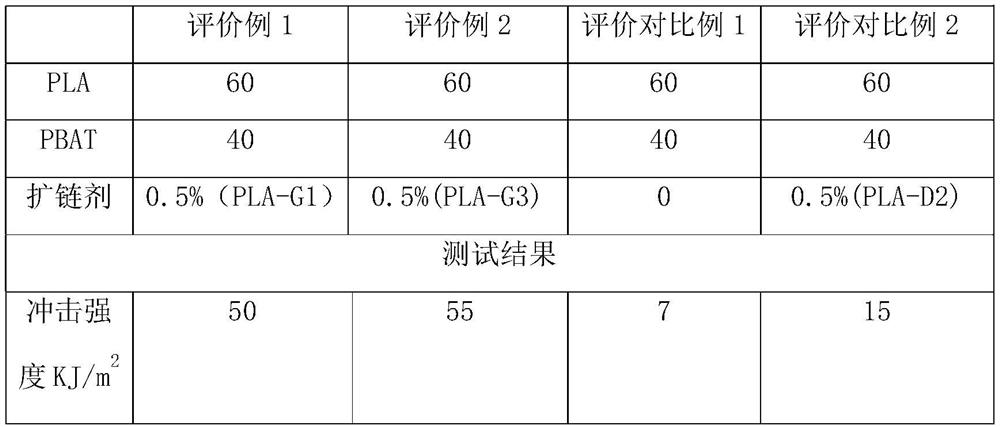

Embodiment 1

[0042] Weigh 60% of polylactic acid resin and 40% of glycidyl methacrylate copolymer SG-15 as mixed material by weight percentage; add the mixed material to the twin-screw extruder for melt extrusion, and granulate to obtain granular products (i.e. PLA-g-GMA copolymer material). In this scheme, the temperature of the co-rotating twin-screw extruder is 140°C, 160°C, 180°C, 200°C, 200°C, 200°C, 200°C, 220°C, 200°C, 200°C, 200°C, 190°C. The length-diameter ratio of the twin-screw was 35, and the screw speed was 300 rpm. A melt grafting reaction is carried out. After dicing and post-processing, a poly(lactic acid)-based graft product is obtained. The epoxy content and terminal carboxyl group concentration of the samples are shown in Table 1.

Embodiment 2

[0044] Take by weight 70% of polylactic acid resin, 30% of glycidyl methacrylate copolymer SG-30 as mixed material; add mixed material to twin-screw extruder for melt extrusion, granulation to obtain granular product (i.e. PLA-g-GMA copolymer material). In this scheme, the temperature of the co-rotating twin-screw extruder is 140°C, 160°C, 180°C, 200°C, 200°C, 200°C, 200°C, 220°C, 200°C, 200°C, 200°C, 180°C. The length-diameter ratio of the twin-screw was 45, and the screw speed was 400 rpm. A melt grafting reaction is carried out. After dicing and post-processing, a poly(lactic acid)-based graft product is obtained. The epoxy content and terminal carboxyl group concentration of the samples are shown in Table 1.

Embodiment 3

[0046] Take by weight polylactic acid resin 80%, glycidyl methacrylate copolymer SG-60 20% as mixed material; add mixed material to twin-screw extruder for melt extrusion, granulation to obtain granular product (i.e. PLA-g-GMA copolymer material). In this scheme, the temperature of the co-rotating twin-screw extruder is 140°C, 150°C, 180°C, 200°C, 200°C, 200°C, 200°C, 220°C, 200°C, 200°C, 200°C, 180°C. The length-diameter ratio of the twin-screw was 55, and the screw speed was 500 rpm. A melt grafting reaction is carried out. After dicing and post-processing, a poly(lactic acid)-based graft product is obtained. The epoxy content and terminal carboxyl group concentration of the samples are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| collision energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com