Fabricated hollow outer wall structure and mounting method

A wall structure, prefabricated technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of escaping crowd injury, insufficient strength of hollow block walls, distortion and deformation, etc., to reduce damage, reduce The effect of the overall breakaway time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

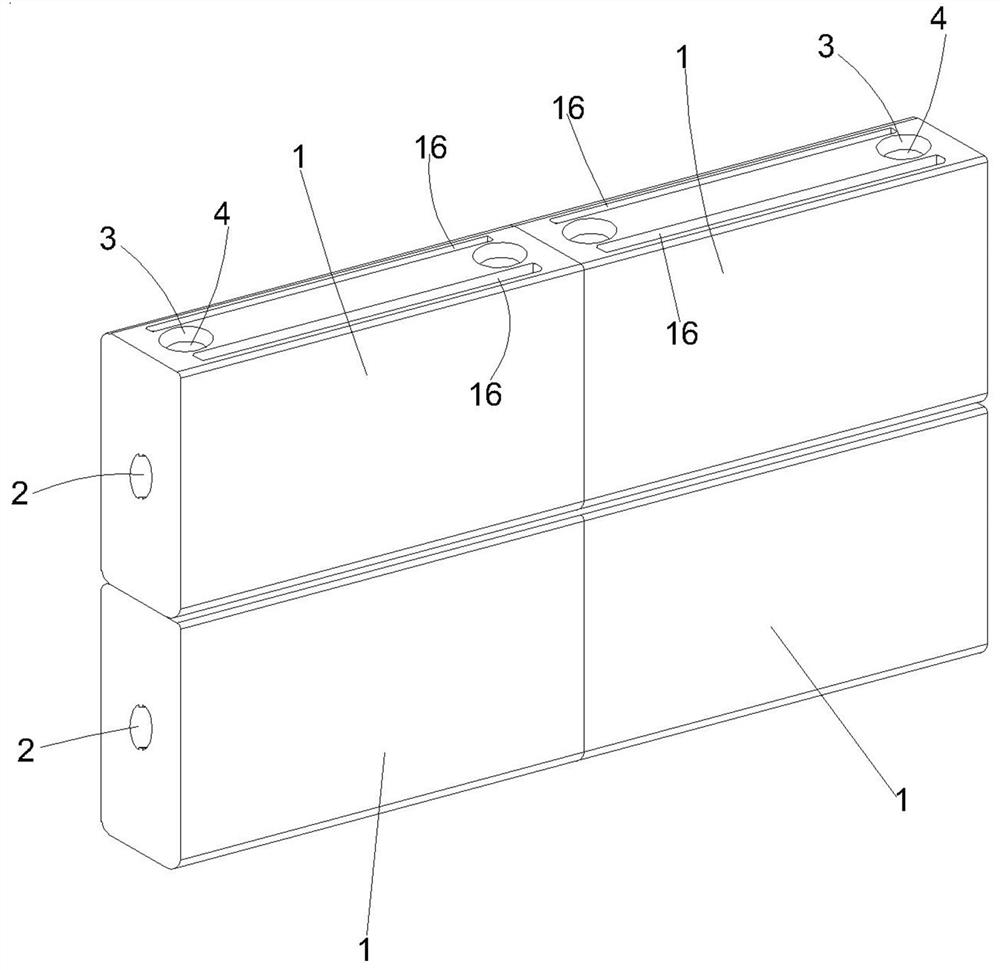

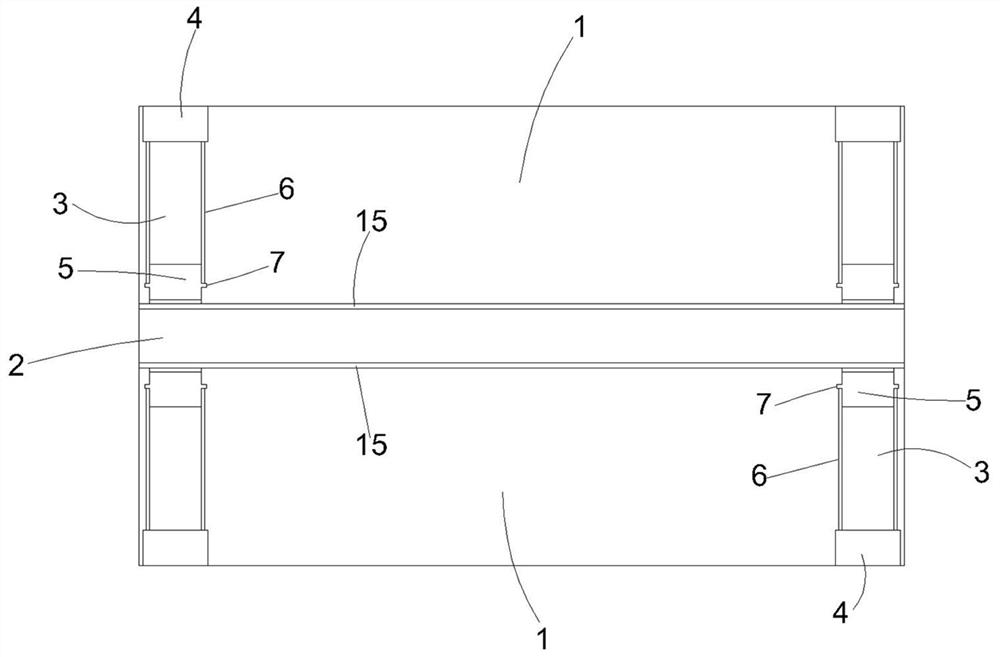

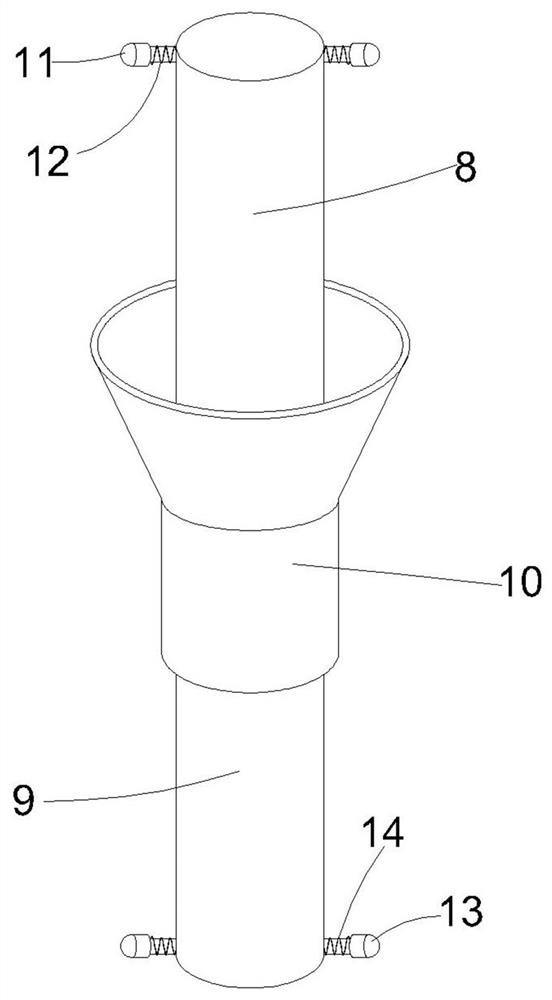

[0054] A prefabricated hollow outer wall structure and installation method, the structure of which is as follows Figure 1-Figure 12 As shown, it includes a block body 1, and also includes a block fixing device matched with the adjacent block body 1; the block body 1 is provided with a block anti-seismic device 10 matched with the block fixing device; the block body 1 is provided with an adjusting sliding mechanism matched with the block fixing device on the inner sides of the opposite sides. The adjustment sliding mechanism includes 4 groups of vertical sliding chambers arranged on the inner side of the block body 1 and a horizontal sliding chamber 2 perpendicular to the vertical sliding chamber 4 in the block body 1; any 4 groups of vertical sliding chambers include A pair of vertical sliding cavities 4 that are axisymmetric to the block body 1, a pair of vertical guide chute 6 that is axisymmetric to the vertical sliding cavity 4 is provided on the inner side of any vertica...

Embodiment 2

[0072] A prefabricated hollow outer wall structure and its installation method and method are different from Embodiment 1 in that the movable hemispherical shell structure 107 includes three movable hemispherical shells 110 that are axially symmetrical to the anti-seismic sphere 106 .

Embodiment 3

[0074] A prefabricated hollow outer wall structure and its installation method and method are different from Embodiment 1 in that the movable hemispherical shell structure 107 includes four movable hemispherical shells 110 that are axially symmetrical to the anti-seismic sphere 106 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com