High-precision step surface shape measurement method and device based on spectral confocal

A spectral confocal and measurement method technology, applied in the field of high-precision step-by-step surface shape measurement methods and devices, can solve problems such as poor stability, low measurement accuracy, and long measurement time, achieve strong stability, realize three-dimensional shape, Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

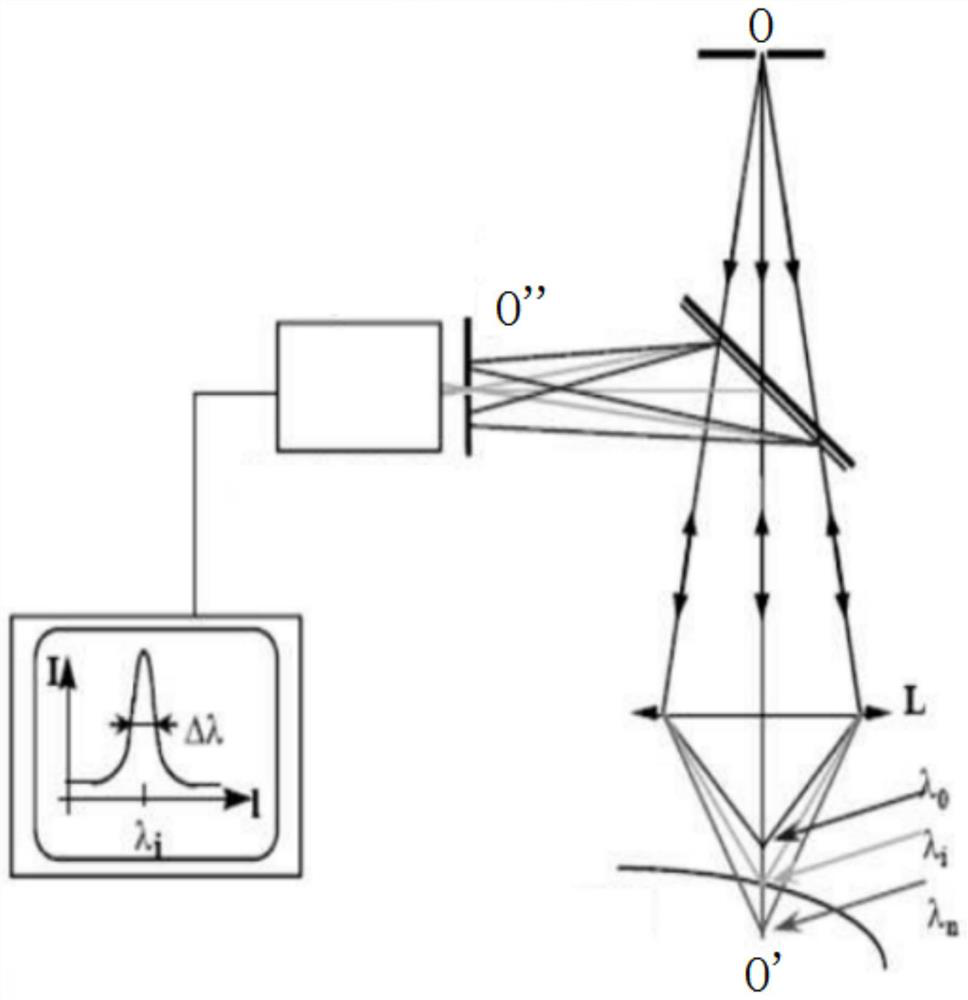

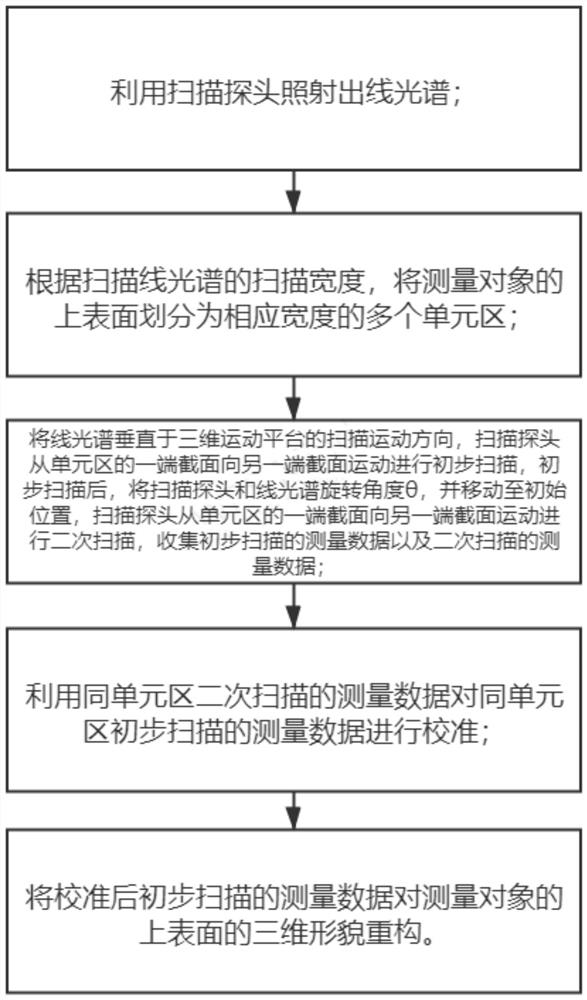

[0033] Such as figure 1 As shown, the embodiments of the present invention provide a high-precision step-by-step surface shape measurement method based on spectral confocal, including:

[0034] Step 1, using the scanning probe to irradiate the line spectrum;

[0035] Step 2, according to the scan width of the scan line spectrum, the upper surface of the measurement object is divided into a plurality of unit areas of corresponding width;

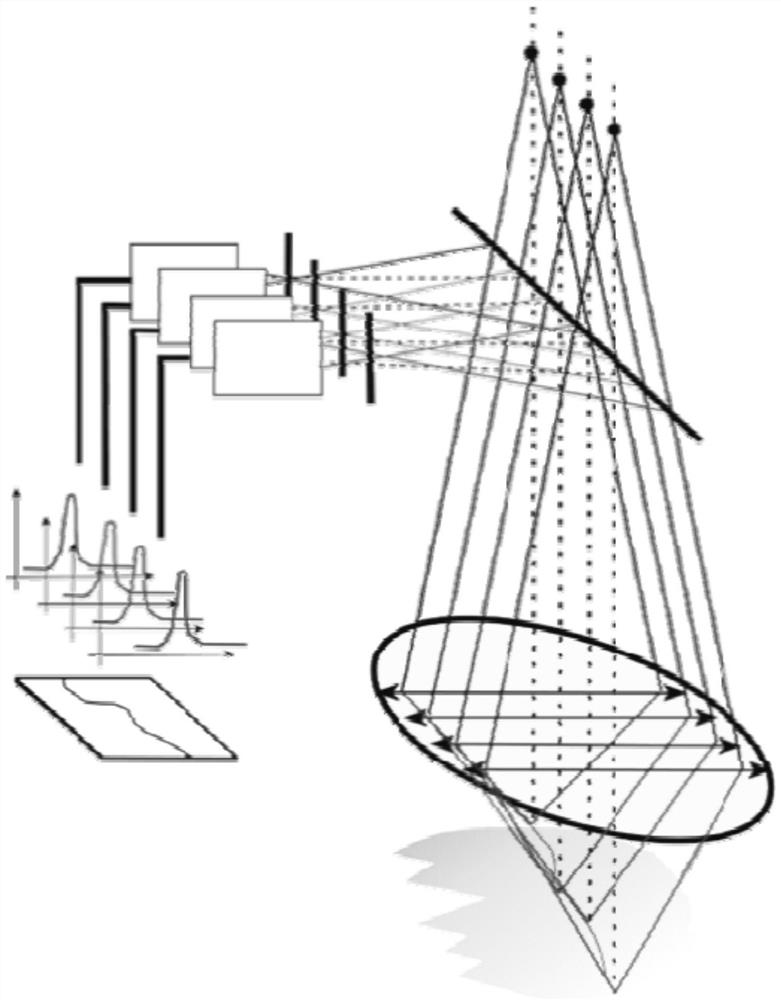

[0036] Step 3: Scan each unit area separately by moving the scanning probe; when scanning the unit area, the line spectrum is perpendicular to the scanning movement direction of the three-dimensional motion platform, and the scanning probe moves from one end section of the unit area to the other end section for preliminary Scanning, after preliminary scanning, rotate the scanning probe and the line spectrum by an angle θ, and 0°<θ<180°, in this embodiment, θ=90°, and move to the initial position, the scanning probe is cross-sectional from on...

Embodiment 2

[0043] Such as Figure 8 As shown, the embodiments of the present invention provide a high-precision step-by-step surface profile measurement device based on spectral confocal, including: a measurement platform 1, a three-dimensional motion platform is arranged on the measurement platform 1, and the three-dimensional motion platform is set There are X-direction slide table 2, Y-direction slide table 3 and Z-direction slide table 4, said Z-direction slide table 4 is provided with an angle adjustment mechanism 5, and the bottom of said angle adjustment mechanism 5 is provided with a scanning probe 6, said The scanning probe 6 is provided with a line spectrum displacement measurement system, and the line spectrum displacement measurement system irradiates a line spectrum 7 .

[0044] The high-precision step-by-step surface shape measurement device based on spectral confocal described in the above-mentioned embodiments of the present invention, the measurement platform is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com