Preparation method of resistance-type stress-strain composite sensing material

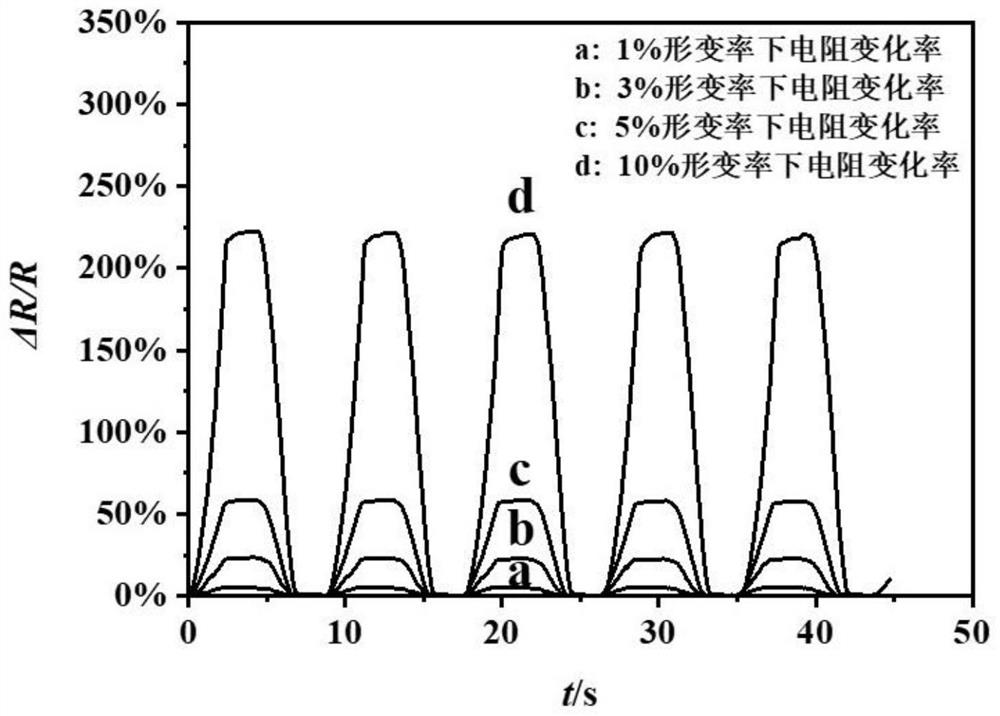

A technology of stress-strain and composite sensing, which is applied in the measurement of the properties and forces of piezoelectric resistance materials, nanotechnology for materials and surface science, and measurement of electric/magnetic solid deformation. Problems such as low utilization rate and high preparation cost can achieve the effect of controllable shape, variable composition and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

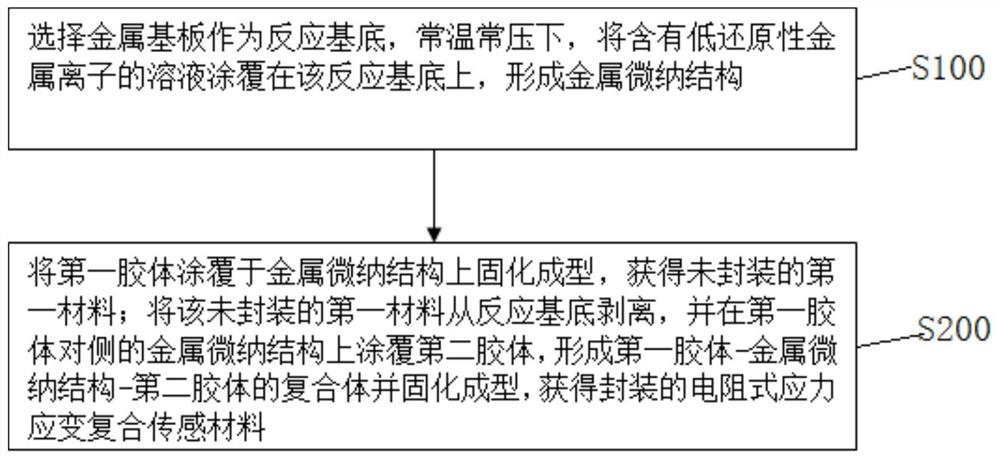

[0027] In one embodiment, such as figure 1 As shown, the present disclosure provides a method for preparing a resistive stress-strain composite sensing material, comprising the following steps:

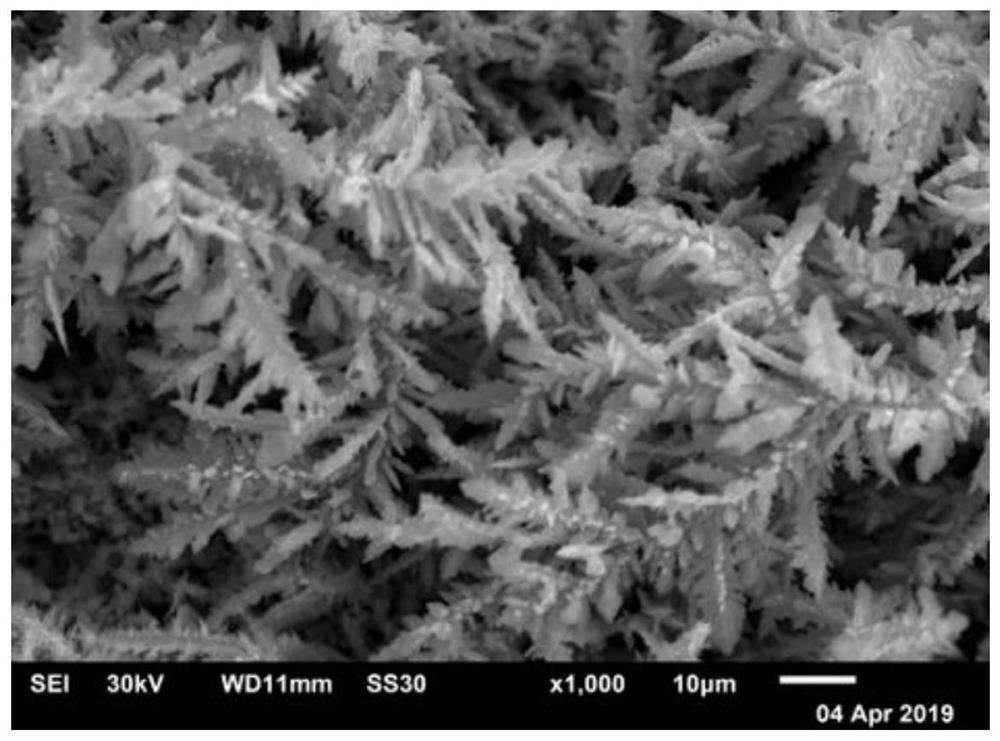

[0028] S100: select a metal substrate as a reaction substrate, and apply a solution containing low reducing metal ions on the reaction substrate at normal temperature and pressure to form a metal micro-nano structure;

[0029] In this step, the reaction substrate is placed in the reaction vessel, and the solution containing low reducing metal ions is drip-coated on the reaction substrate with a dropper. Since the metal ions can undergo in-situ displacement reactions with the metal ions in the reaction substrate, Thus forming a metal micro-nano structure.

[0030] It should be understood that the low reducibility here is a relative concept, that is, the metal ions in the solution have lower reducibility than the metal contained in the metal substrate. Only when this condition is met, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com