Preparation method of graphene-based dual-channel flexible polymorphic stress sensor

A sensor and graphene technology, applied in the direction of instruments, measuring force, measuring devices, etc., can solve the problem that the sensor is susceptible to interference, and achieve the effect of optimizing the stress detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

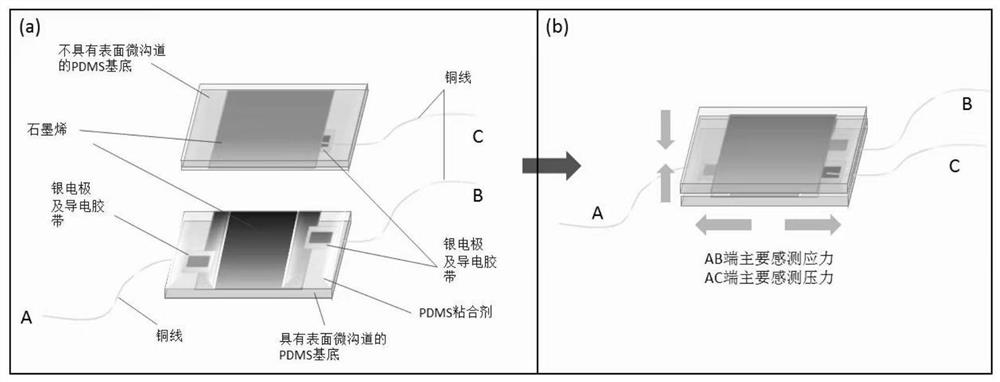

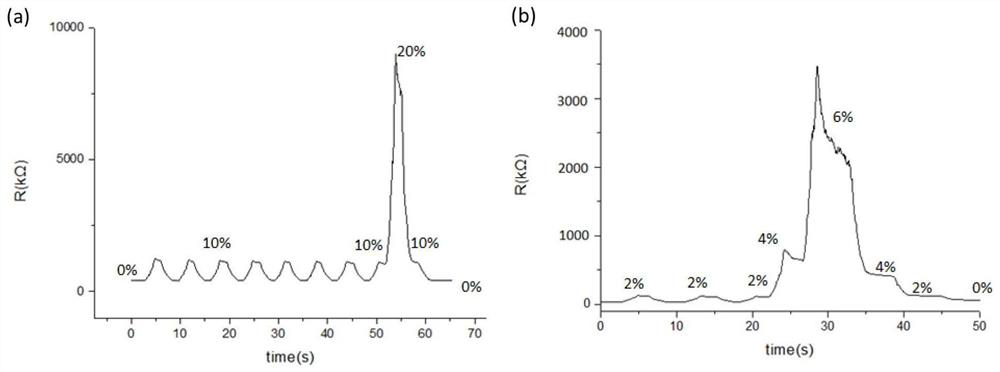

[0020] This embodiment provides a graphene dual-channel wearable multi-state stress sensor applied to palm movement monitoring, and the wearable sensor is attached to the jaw of a human body. The specific implementation method is as follows:

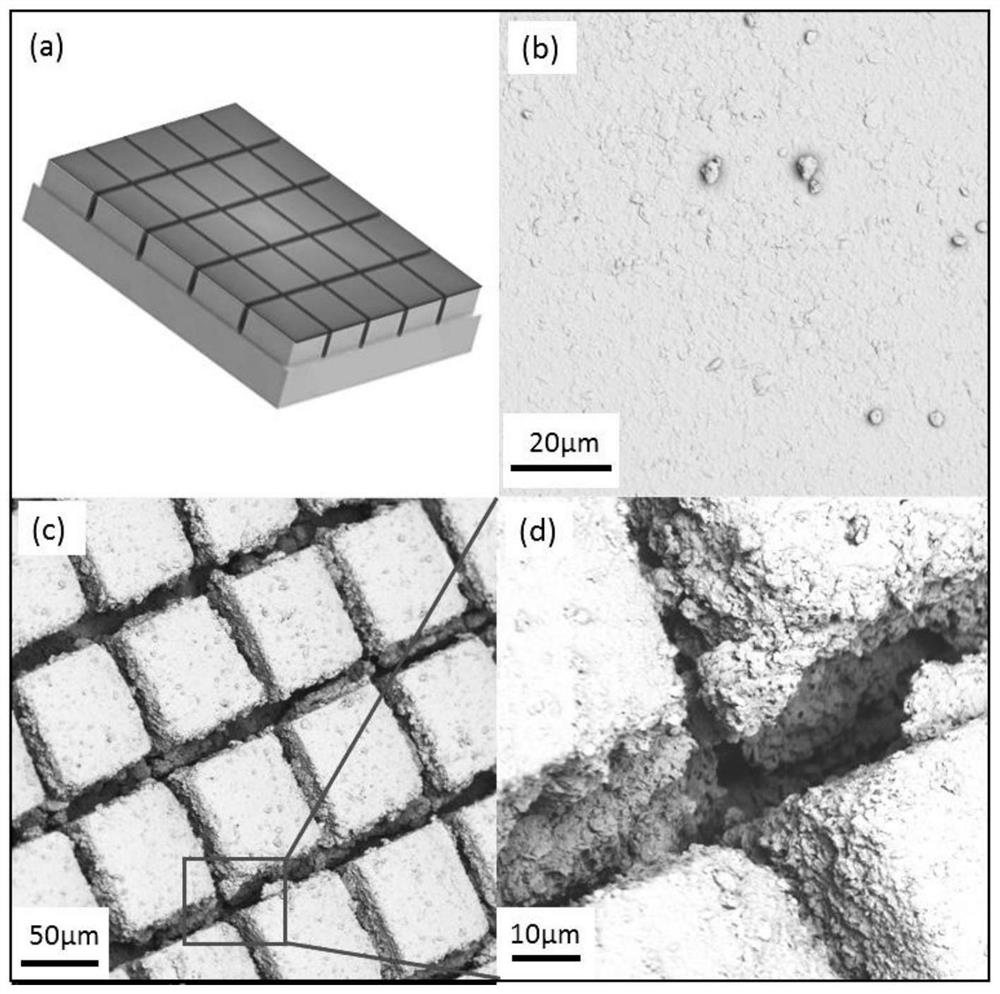

[0021] (1) Preparation of PDMS substrate

[0022] Use l-edit to draw a square grid pattern with a line width of 30 μm and a grid side length of 100 μm. The total area of the pattern is 1.5cmx1.5cm. A mask is prepared by photolithography for subsequent dry etching. The silicon wafer was dry-etched with an etching depth of 50 μm, and a silicon wafer having a square groove array with a side length of 100 μm and a depth of 50 μm was obtained after degelling.

[0023] Mix epoxy resin structural glue (PDMS A glue) and acrylate structural glue (PDMS B glue) at a volume fraction of 10:1, and stir evenly with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com