Ultrasonic phased array detection device and method for automobile third-generation hub bearing outer ring

An ultrasonic phased array and hub bearing technology, which is used in measurement devices, the use of sonic/ultrasonic/infrasonic waves to analyze solids, and the testing of mechanical components to improve detection efficiency, improve imaging accuracy and computing speed, and enhance detection sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

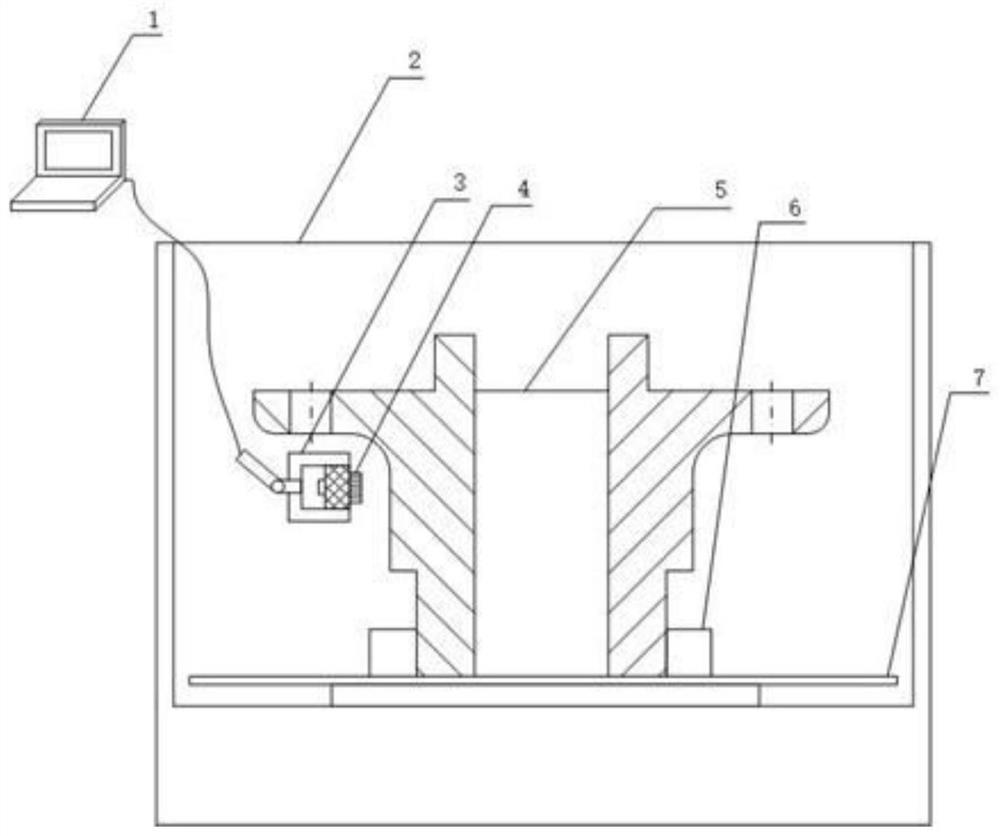

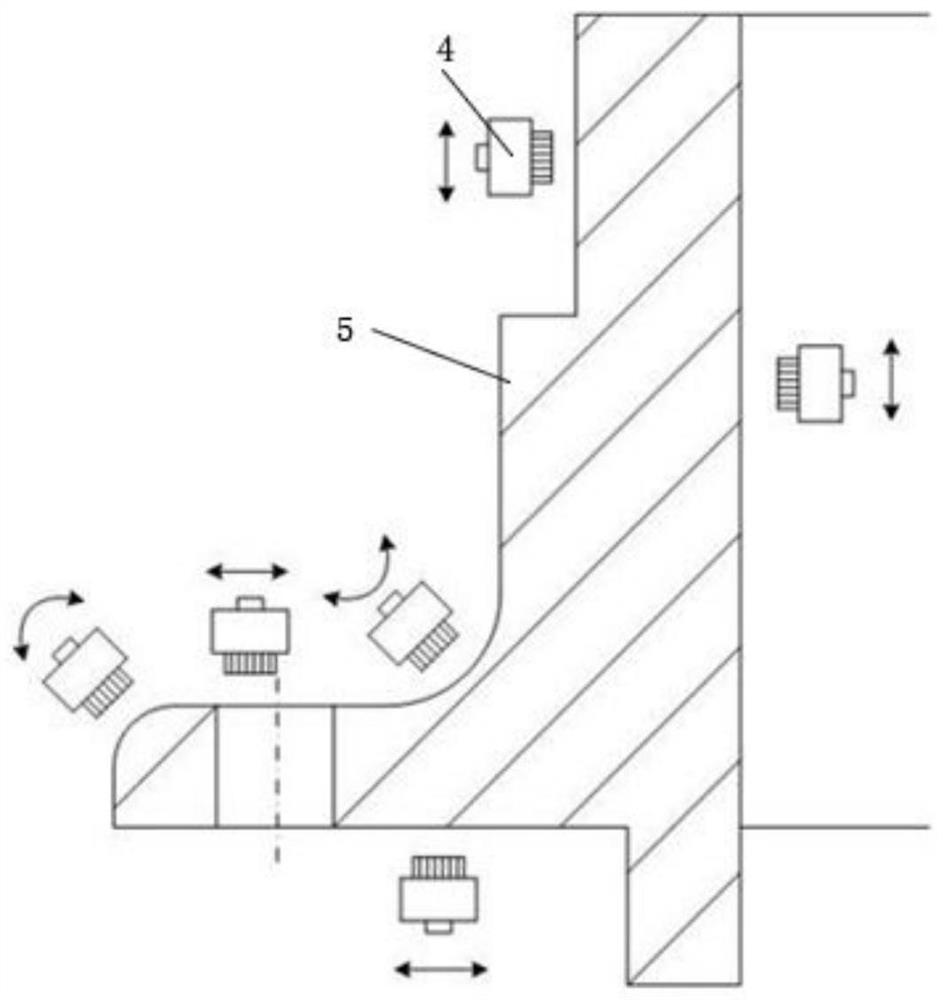

[0030] Such as figure 1 As shown, the ultrasonic phased array detection device for the outer ring of the third-generation wheel hub bearing of the automobile includes an ultrasonic detector 1, a water tank 2, a six-degree-of-freedom manipulator 3, an ultrasonic phased-array probe 4, and a rotating support. The ultrasonic detector passes through the six-degree-of-freedom manipulator Connected with the ultrasonic phased array probe, the rotating support includes a four-jaw chuck 6 and a rotating tray 7. The rotating tray is installed inside the water tank, and the four-jaw chuck is installed on the rotating tray, which is used to clamp the outer surface of the wheel hub bearing to be tested. Circle 5.

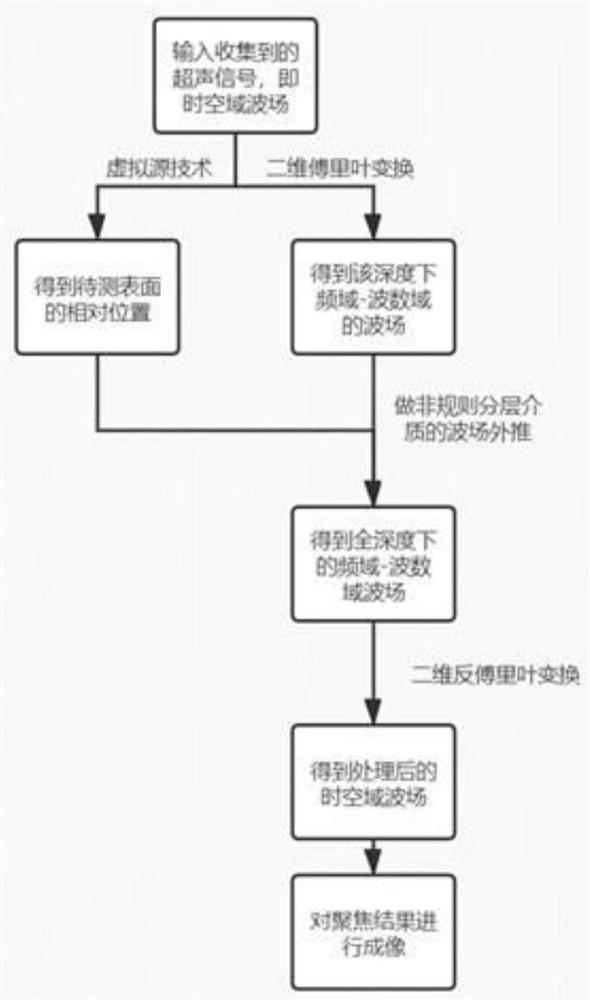

[0031] Such as image 3 As shown, the present invention adopts the water immersion method to place ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com