A collaborative robust optimization design method for composite support structures with topology and materials

A support structure and composite material technology, applied in design optimization/simulation, computer-aided design, calculation, etc., can solve problems that affect collaborative robust optimization design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

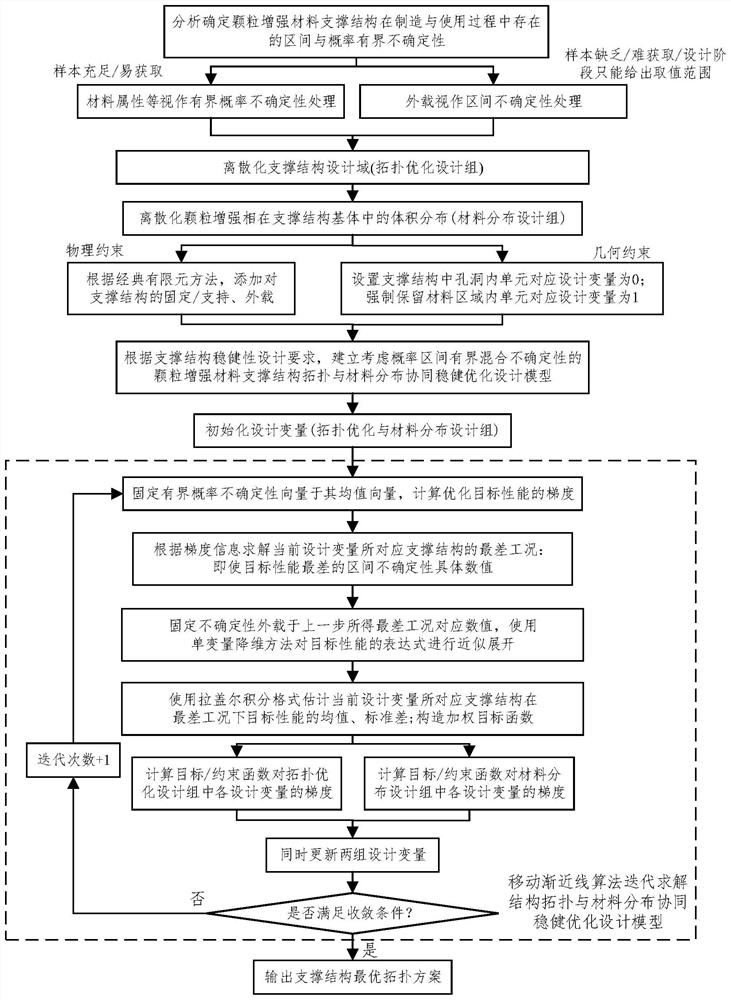

[0078] The information involved in the figure is the actual application data of the present invention in the topology and material collaborative robust optimization design of the cutter head support structure in a certain type of shield machine, figure 1 It is a flow chart of the composite material support structure topology and material collaborative robust optimization design.

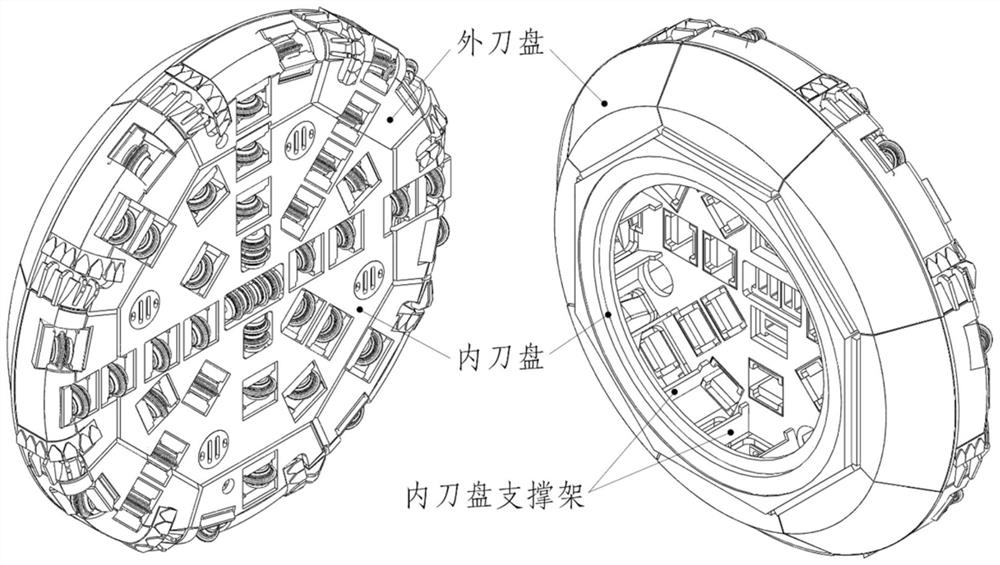

[0079] 1. to figure 2 The cutterhead support structure of a certain type of shield machine made of high-strength low-alloy steel material reinforced with SiC particles with a maximum allowable volume fraction of 2% is used as the research object, and the uncertainty of the support structure in the process of manufacturing and service is considered:

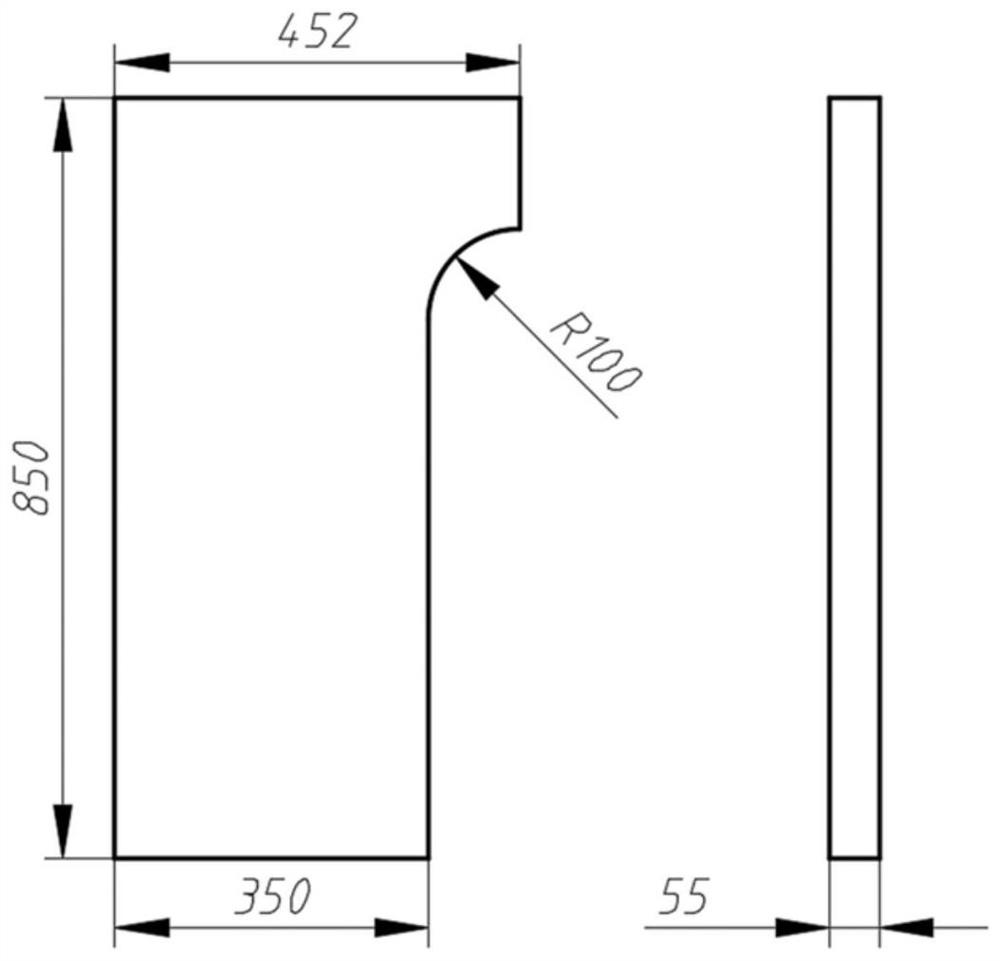

[0080] 1.1) image 3 is the relevant dimensions of the initial design of the cutter head support structure in the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com