Cover plate structure, chip structure and airtight chip structure

A chip structure and airtight technology, applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of large volume and high cost of airtight packaging, and achieve the effect of small size and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

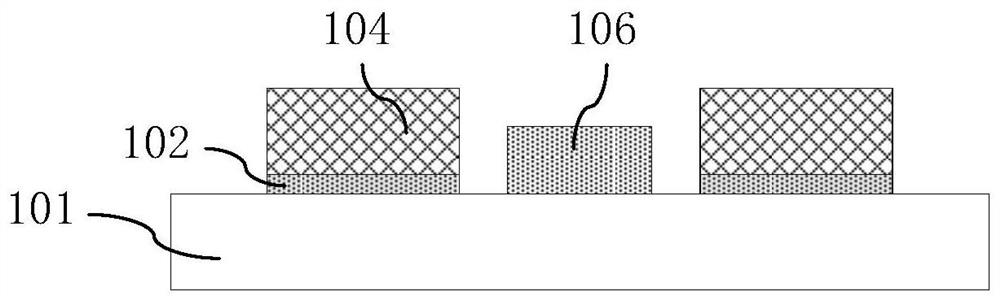

[0030] Such as figure 1 as shown, figure 1 It is a cover plate structure provided by Embodiment 1 of the present invention, including a cover plate disc 101, a first metal layer 102 is provided on the front side of the cover plate disc 101, and a The first circuit patterns 104 are electrically connected to obtain a cover wafer.

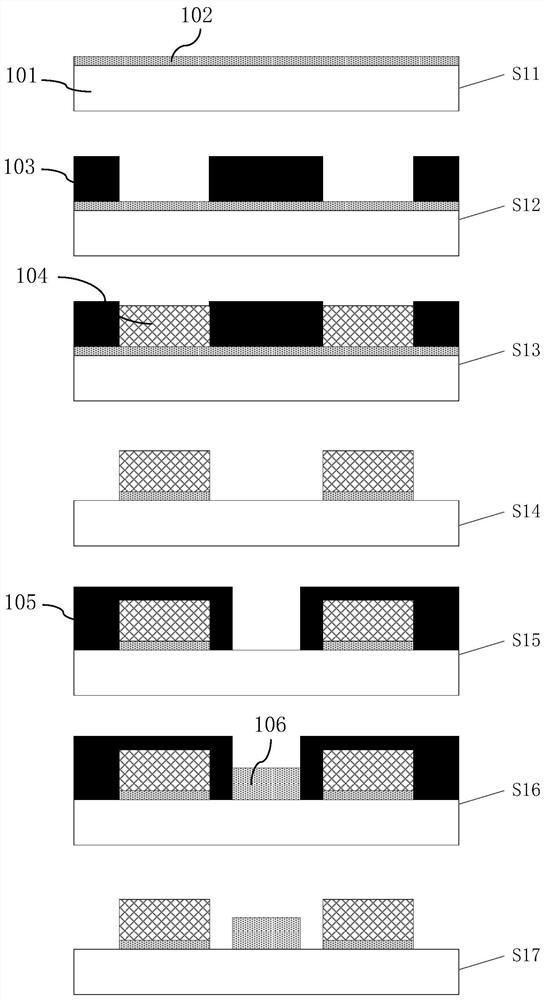

[0031] Specifically, such as figure 2 As shown, the cover plate structure is packaged by the following steps:

[0032] Step S11, making the first metal layer 102 on the front side of the cover plate 101: Electroplating the first metal layer 102 on the front side of the cover plate 101 by electroless copper plating, sputtering or vapor deposition of Ti, TiW, Cr, Co, etc. barrier layer and adhesion layer, the material of the cover plate 101 can be silicon, glass, metal and other wafer materials;

[0033] Step S12, making a first mask 103 on the first metal layer 102 that wraps the area to be sealed or the sensing area of the chip: electroplating ...

Embodiment 2

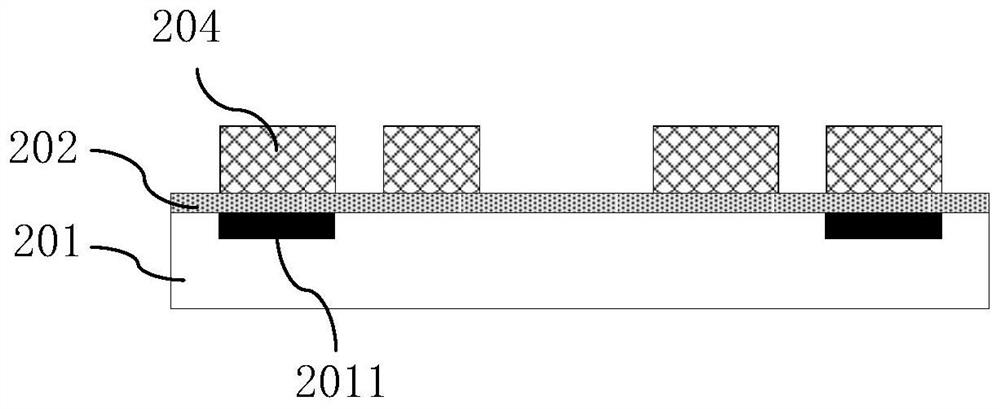

[0045] Such as image 3 as shown, image 3It is a chip structure provided by Embodiment 2 of the present invention, including a chip 201, a second metal layer 202 is provided on the front side of the chip 201, and a second metal layer 202 is provided at a position corresponding to the bonding pad 2011 of the chip 202 and the first circuit pattern of the cover wafer. There is a third circuit pattern 204 electrically connected to the second metal layer 202, resulting in a chip wafer.

[0046] Specifically, as Figure 4 As shown, the chip structure is packaged by the following steps:

[0047] Step S21, making the second metal layer 202 on the front of the chip 201: electroplating the second metal layer 202 on the front of the chip 201 by electroless copper plating, sputtering or vapor deposition of metals such as Ti, TiW, Cr, Co, etc., to act as a barrier layer and the adhesion layer, the chip 201 is a chip that completes processes such as application-specific integrated circu...

Embodiment 3

[0055] Such as Figure 5 as shown, Figure 5 It is a structural schematic diagram of an airtight chip structure provided by Embodiment 3 of the present invention, including the aforementioned cover structure, the aforementioned chip structure, and the substrate 303, and the cover wafer 302 of the cover structure The front surface of the chip wafer 301 of the chip structure is electrically connected through the first metal layer and the second metal layer, so that the first circuit pattern of the cover wafer 302 wraps the area to be sealed or the sensing area 3011 of the chip wafer 301 , the back of the chip wafer 301 is attached to the front of the substrate 303, and the substrate 303 is electrically connected to the pad 3012 of the chip wafer 301, and the cover wafer 302, the chip wafer 301 and the substrate 303 are embedded in the organic resin 304 Inside.

[0056] Specifically, as Figure 6 As shown, the hermetic chip structure is packaged by the following steps:

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com