MEMS device airtightness packaging method

An encapsulation method and air tightness technology, applied in the field of MEMS processing, can solve the problems of vacuum degree limitation, difficult control, device damage, etc., and achieve the effect of small internal stress and large bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following specific examples help to understand the characteristics and advantages of the present invention, but the implementation of the present invention is by no means limited to the described examples.

[0036] A specific embodiment of the hermetic packaging method of the present invention includes as Figure 6 to Figure 12 Process steps shown:

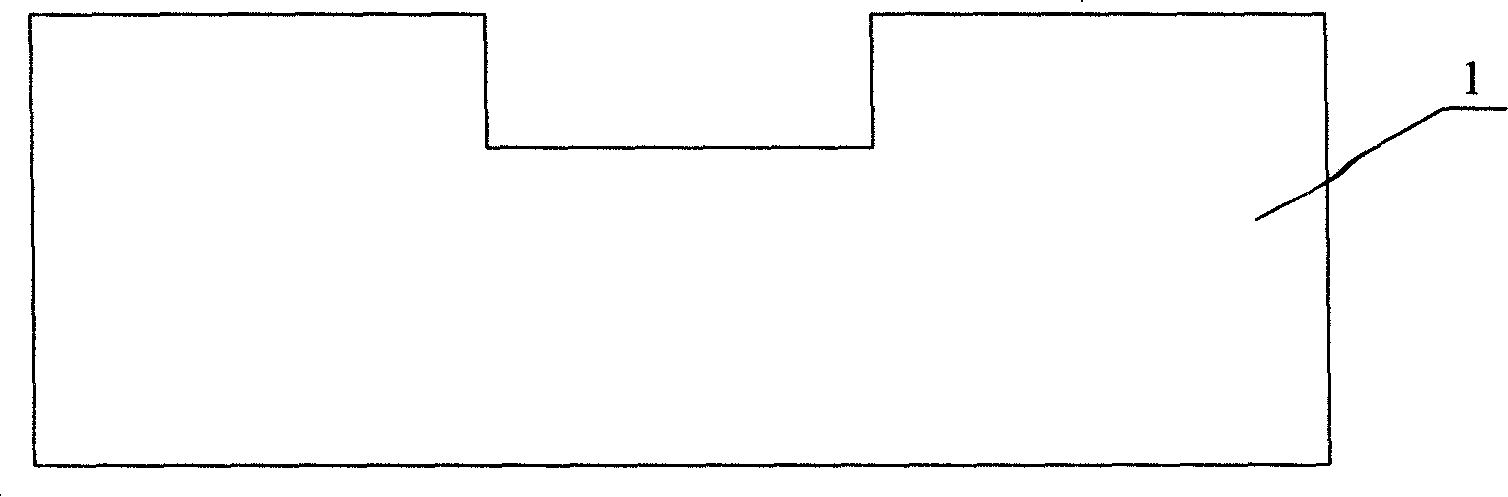

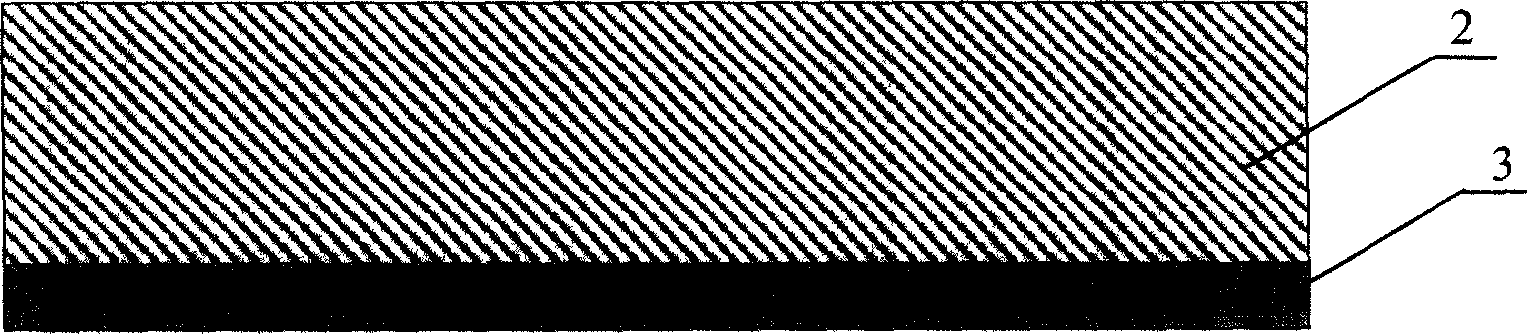

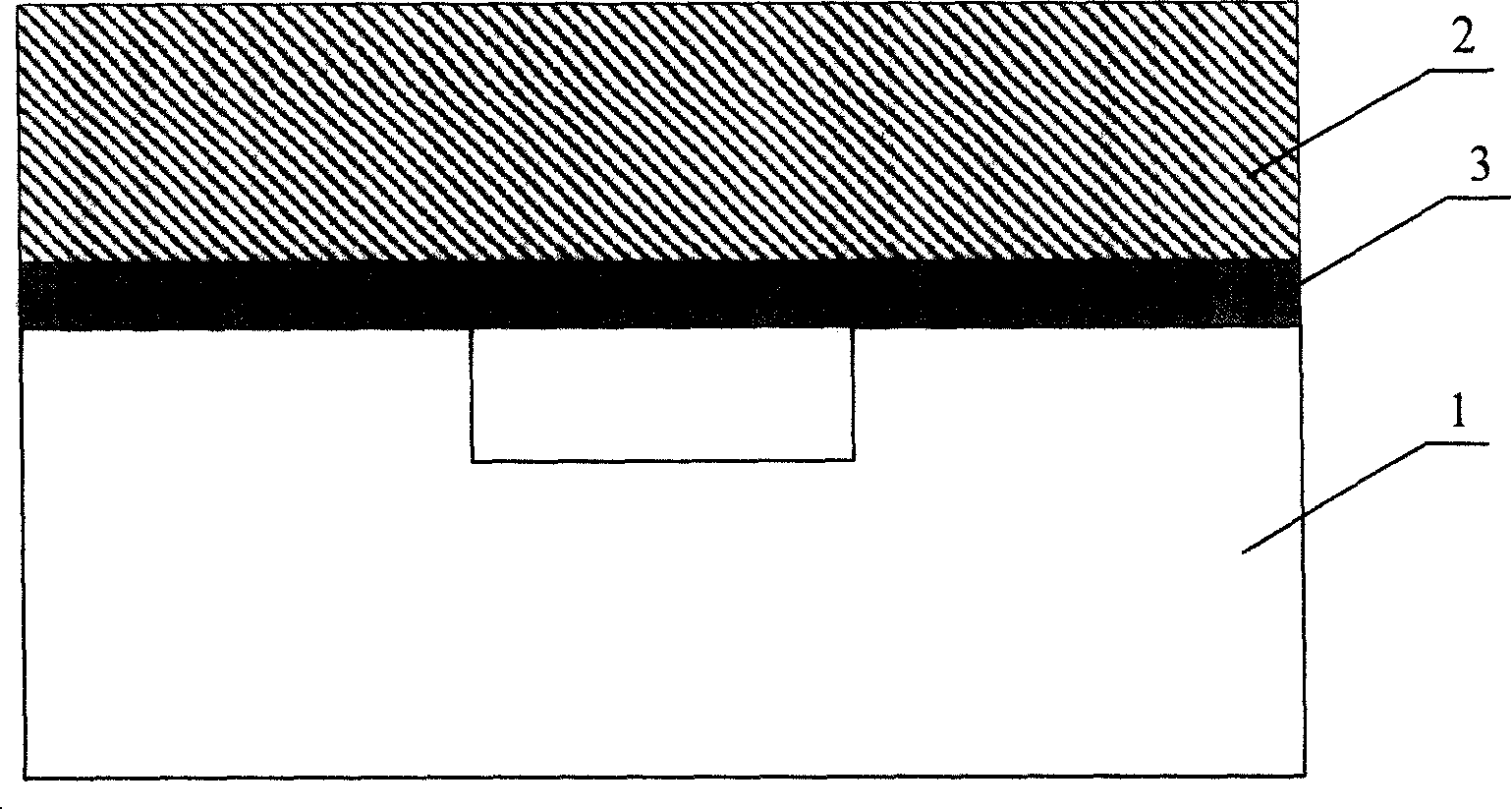

[0037] 1. Preparation of the chamber and pre-preparation of the top cover

[0038] see Image 6 , the material of substrate A for processing cavity grooves is glass, and the designed cavity is etched with HF through the mask plate. The substrate B used as the top cover is a silicon wafer. First, a silicon dioxide layer 5 and a silicon nitride layer 6 are thermally grown on the silicon wafer, and then photoetched on the silicon nitride according to the size and shape of the groove on the substrate A. Etching defines the pattern of the silicon nitride film.

[0039] When the photoresist outside the silicon cap is remo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com