Auxiliary empty package detection device of carton packaging machine

A technology of packaging machinery and detection device is applied in the field of auxiliary empty bag detection device of carton packaging machinery, which can solve the problems of reducing production efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

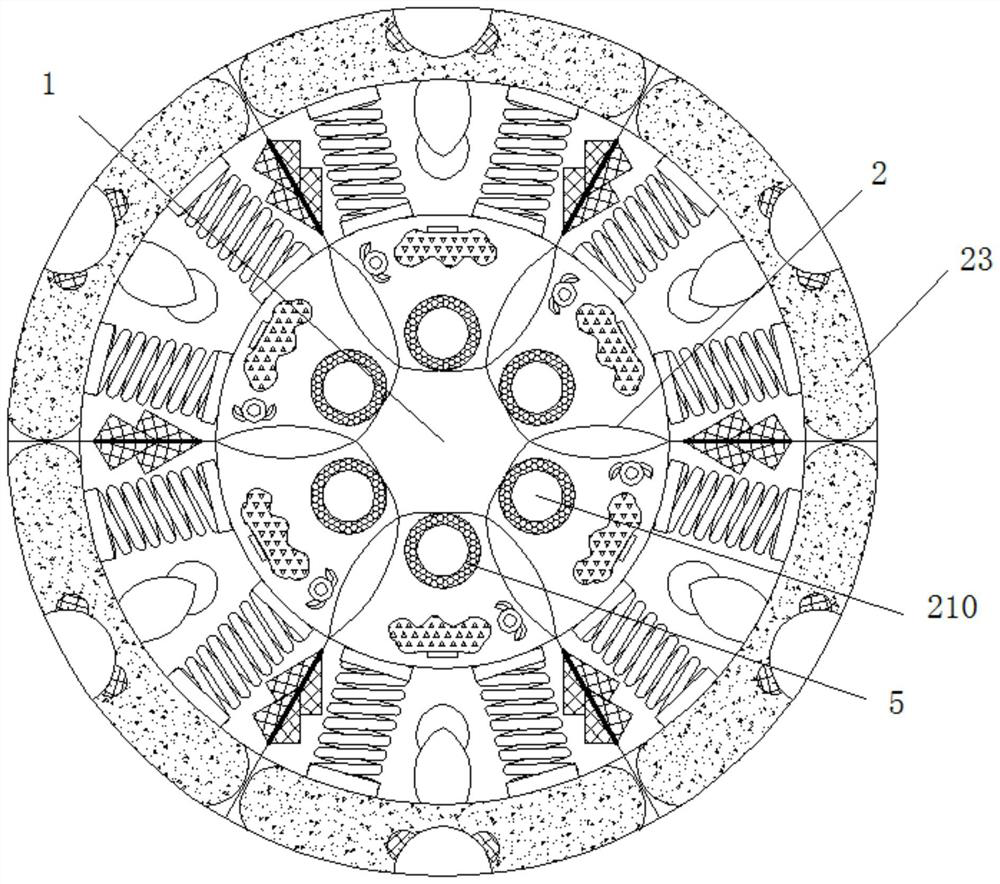

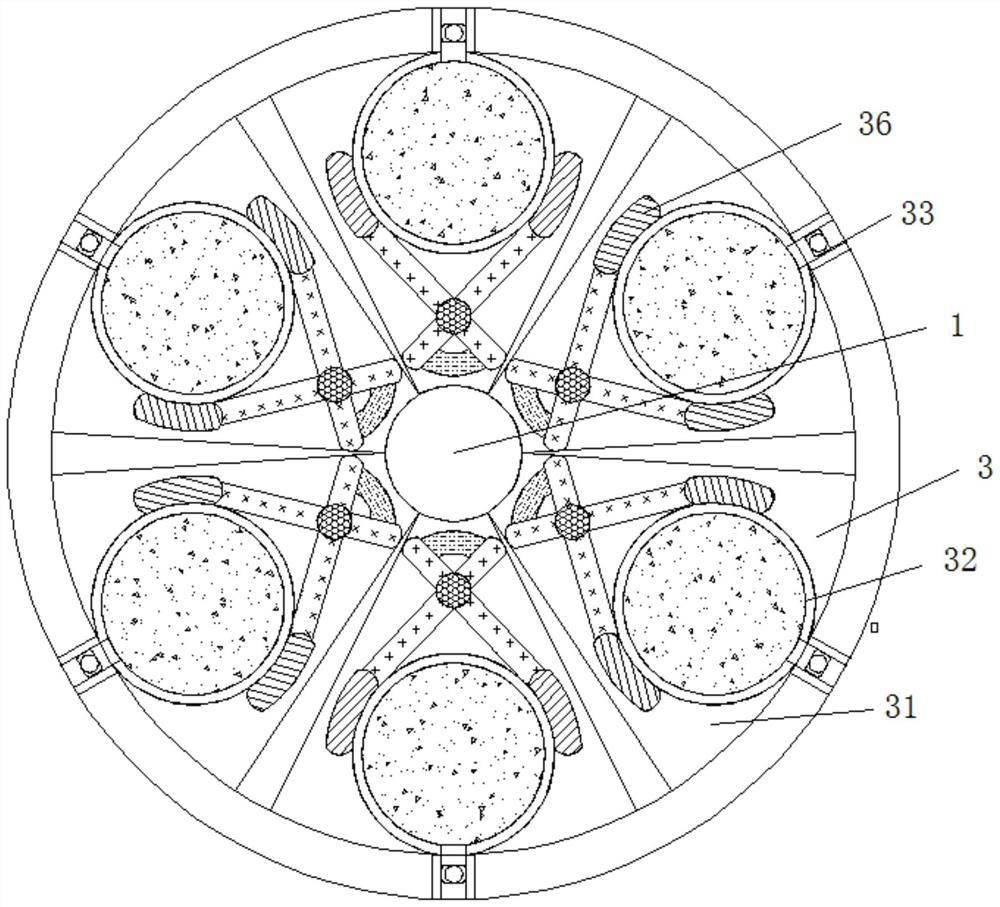

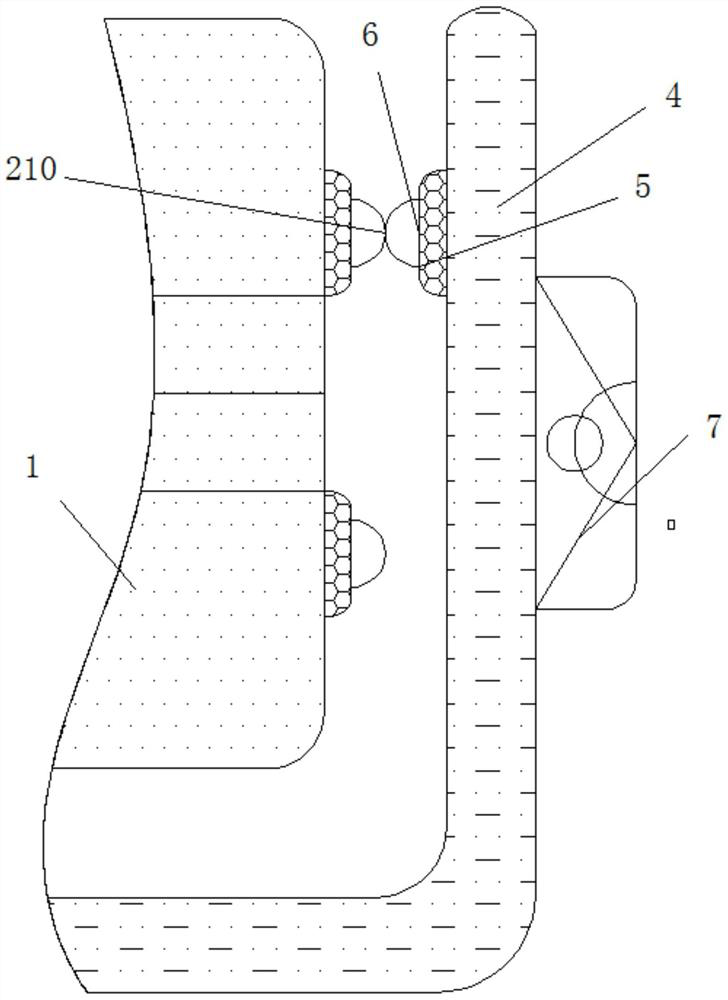

[0027] see Figure 1-4 , a carton packaging mechanical auxiliary empty package detection device, including a rotating roller shaft 1, also includes a detection component 2, a marking component 3, an equipment housing 4, an elastic pad 5, a moving contact 6, an alarm 7, a rotating roller The inside of the shaft 1 is fixedly connected with the detection component 2, the inside of the rotating roller shaft 1 is fixedly connected with the marking component 3, the outer side of the rotating roller shaft 1 is fixedly connected with the equipment shell 4, and the inside of the equipment shell 4 is fixedly connected with the elastic pad 5, the elastic pad The inner side of the block 5 is fixedly connected with the movable contact 6, and the outer side of the equipment casing 4 is fixedly connected with the alarm 7;

[0028] The detection assembly 2 includes a mounting groove 21, a return spring 22, a magnet push block 23, a photoresistor 24, an electromagnet 25, a dielectric plate 26,...

Embodiment 2

[0030] see Figure 1-5 , a carton packaging mechanical auxiliary empty package detection device, including a rotating roller shaft 1, also includes a detection component 2, a marking component 3, an equipment housing 4, an elastic pad 5, a moving contact 6, an alarm 7, a rotating roller The inside of the shaft 1 is fixedly connected with the detection component 2, the inside of the rotating roller shaft 1 is fixedly connected with the marking component 3, the outer side of the rotating roller shaft 1 is fixedly connected with the equipment shell 4, and the inside of the equipment shell 4 is fixedly connected with the elastic pad 5, the elastic pad The inner side of the block 5 is fixedly connected with the movable contact 6, and the outer side of the equipment casing 4 is fixedly connected with the alarm 7;

[0031]The detection assembly 2 includes a mounting groove 21, a return spring 22, a magnet push block 23, a photoresistor 24, an electromagnet 25, a dielectric plate 26, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com