High-temperature-resistant composite filtrate reducer for seawater drilling fluid and preparation method of high-temperature-resistant composite filtrate reducer

A technology of fluid loss reducer and drilling fluid, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of difficulty in obtaining fluid loss reduction effect, poor high temperature resistance performance, etc., and achieve excellent fluid loss reduction performance. and thermal stability, excellent filtration performance, and easy biodegradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A high temperature resistant composite fluid loss reducer for seawater drilling fluid, characterized in that, based on the total mass of the composite fluid loss reducer, the composite fluid loss reducer comprises polymer A-A-C 85wt% and sodium nitrohumate 15wt%.

[0035] Wherein, based on the total mass of the polymer A-A-C, the polymer A-A-C is made of the following raw materials in weight percentage: 20wt% of 2-acrylamide-2-methylpropanesulfonic acid, 30wt% of acrylamide, modified plant source Agent 48wt%, initiator 2wt%.

[0036] The plant-derived modifying agent is nano-microcrystalline cellulose extracted from bagasse, and its preparation method includes the following steps,

[0037] S1: Prepare H with a mass concentration of 65% 2 SO 4 solution;

[0038] S2: Using a high-speed pulverizer to repeatedly pulverize the plant material so that the particle size of the material is 1-3 mm; add 10 times the mass of distilled water to the pulverized material, and stir ...

Embodiment 2

[0047] The preparation method is the same as in Example 1, except that the amount of each component in Example 2 is: based on the total mass of the polymer A-A-C, the polymer A-A-C is made of the following raw materials in weight percentage: 2-acrylamide- 18wt% of 2-methylpropanesulfonic acid, 25wt% of acrylamide, 55wt% of plant-derived modifier, and 2wt% of initiator.

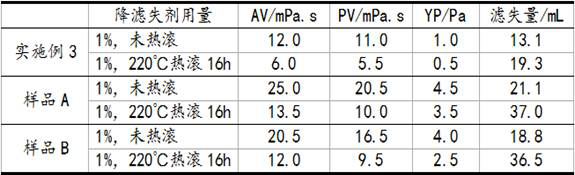

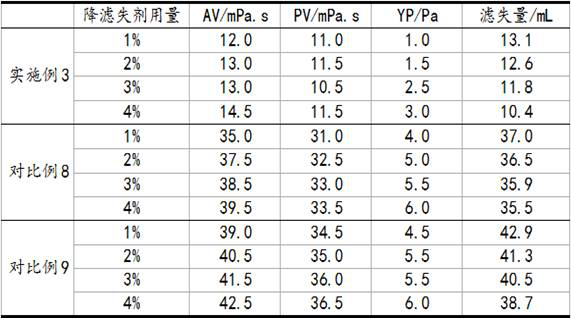

Embodiment 3

[0049] The preparation method is the same as in Example 1, except that the amount of each component in Example 3 is: based on the total mass of the polymer A-A-C, the polymer A-A-C is made of the following raw materials in weight percentage: 2-acrylamide- 25wt% of 2-methylpropanesulfonic acid, 30wt% of acrylamide, 43wt% of plant-derived modifier, and 2wt% of initiator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com