Rust remover, preparation process for rust remover and metal surface rust removal method

A technology of preparation process and derusting agent, which is applied in the field of derusting and derusting agents on metal surfaces, can solve the problems of high cost of inorganic pickling process, difficulty in completely removing rust, and endangering the health of staff, so as to solve the problem of acid mist Emission problems, increase corrosion resistance, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

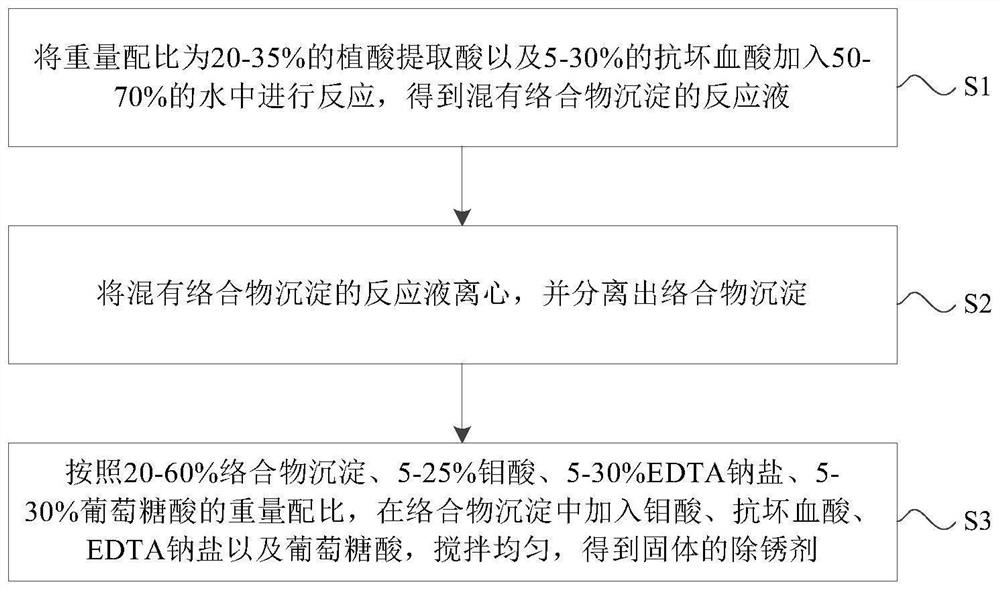

Method used

Image

Examples

Embodiment 1

[0049] Add 20% phytic acid extraction acid and 30% ascorbic acid into 50% water in a weight ratio, and react for 4 hours, and keep the temperature of the water at 65° C. during the reaction. After the full reaction, the reaction solution mixed with complex precipitates was cooled to normal temperature, put into a centrifuge, and centrifuged at a speed of 2000r / min for 1.5 hours, and the supernatant was discarded after centrifugation to separate the complex precipitates.

[0050] According to the weight proportion of 20% complex precipitation, 25% molybdic acid, 30% EDTA sodium salt, 25% gluconic acid, add molybdic acid, ascorbic acid, EDTA sodium salt and gluconic acid in the isolated complex precipitation, Stir evenly to obtain solid rust remover 1.

Embodiment 2

[0052] Add 35% of phytic acid extraction acid and 5% of ascorbic acid into 60% of water, react for 5 hours, and keep the temperature of water at 80° C. during the reaction. After the full reaction, the reaction solution mixed with the complex precipitate was cooled to normal temperature, put into a centrifuge, and centrifuged at a speed of 3000r / min for 1 hour, and the supernatant was discarded after centrifugation to separate the complex precipitate.

[0053] According to the weight proportion of 60% complex precipitation, 5% molybdic acid, 30% EDTA sodium salt, 5% gluconic acid, add molybdic acid, ascorbic acid, EDTA sodium salt and gluconic acid in the isolated complex precipitation, Stir evenly to obtain solid rust remover 2.

Embodiment 3

[0055] Add 25% of phytic acid extracting acid and 10% of ascorbic acid into 70% of water by weight, and react for 5 hours. During the reaction, the temperature of the water is kept at 76°C. After the full reaction, the reaction liquid mixed with the complex precipitate was cooled to normal temperature, put into a centrifuge, and centrifuged at a speed of 2500r / min for 1 hour, and the supernatant was discarded after centrifugation to separate the complex precipitate.

[0056] According to the weight ratio of 33% complex precipitation, 15% molybdic acid, 22% EDTA sodium salt, 30% gluconic acid, add molybdic acid, ascorbic acid, EDTA sodium salt and gluconic acid in the isolated complex precipitation, Stir evenly to obtain solid rust remover 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com