Assembly type PC column-column tenon type bolt connection joint

A connection node, prefabricated technology, applied in the direction of columns, piers, pillars, etc., can solve the problem of low connection and assembly rate of prefabricated columns, reduce on-site secondary processing work, ensure on-site construction quality, and shear bearing capacity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

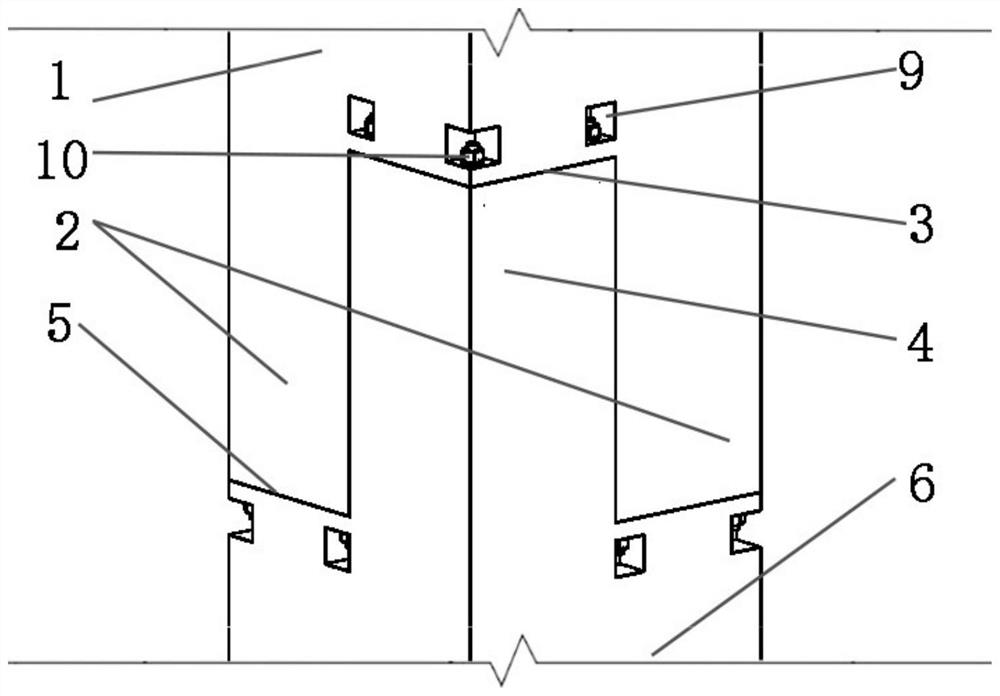

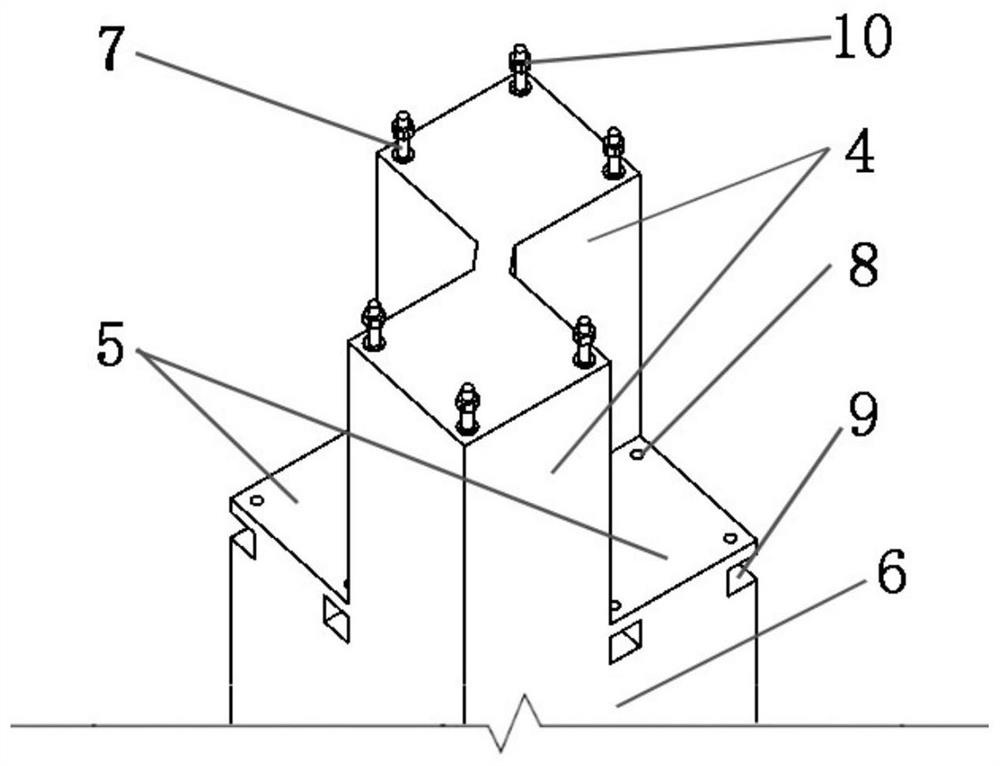

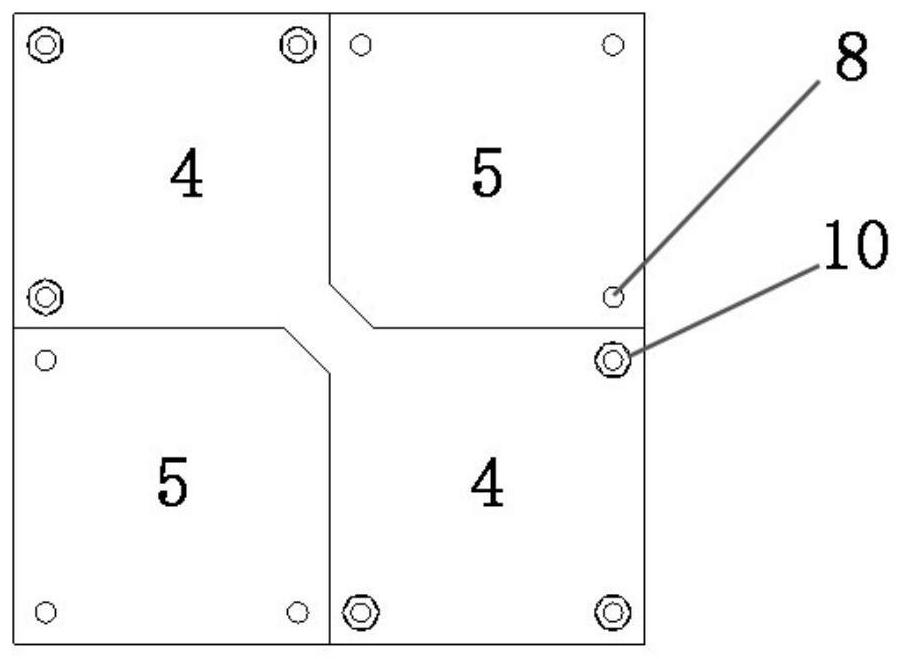

[0024] A prefabricated PC column-column mortise bolt connection node, comprising an upper concrete column 1 and a lower concrete column 6, the bottom of the upper concrete column 1 is intersected with an upper tenon 2 and an upper mortise 3, and the lower concrete column 1 The top of the column 6 is provided with a lower tenon 4 and a lower mortise 5 intersecting in the diagonal direction;

[0025] The upper concrete column 1 is integrally formed with the upper tenon 2, the lower concrete column 6 is integrally formed with the lower tenon 4, and there is no transitional connector in the middle to enhance the overall shear resistance.

[0026] Each angle near the edge of the column at the end of the upper tenon 2 and the lower tenon 4 is reserved with reinforcing bars 7 extending out, and the extending parts of the reinforcing bars 7 are provided with threads....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com