Action execution system based on body type judgment

A technology of action execution and body shape, applied in the direction of image data processing, current slaughter/stunning, instruments, etc., can solve problems such as lack, and achieve the effect of easy operation, reliability and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

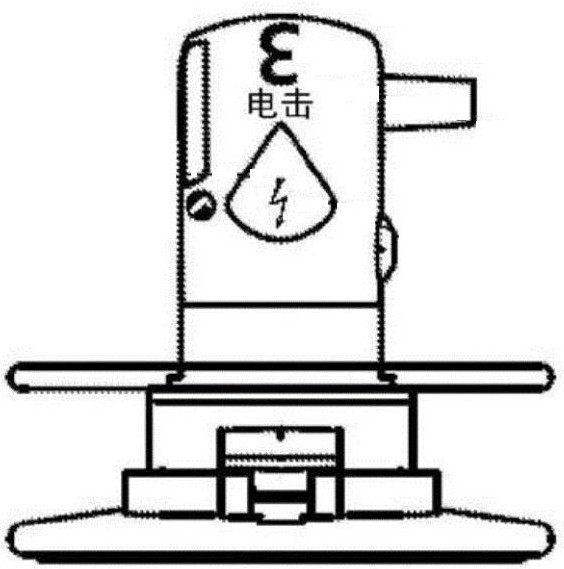

Image

Examples

Embodiment Construction

[0027] The implementation of the body shape judgment based action execution system of the present invention will be described in detail below with reference to the accompanying drawings.

[0028] Cattle (Latin scientific name: Bovine), belonging to the cattle family, is a family under the Bovine subfamily. Bison with 56 chromosomes, yellow cattle with 60 chromosomes, and large-faced cattle with 58 chromosomes can cross and have fertile offspring. They are mammals, prone to Robertsonian translocation (mitochondrial fusion), changing the number of chromosomes, reducing fertility, herbivorous, some species For domestic animals (including cattle, cattle, buffalo and yak). The body is stout, and some bulls have a pair of horns on their heads. Cattle can help humans in agricultural production.

[0029] The common characteristics of bovine animals are strong physique; they have legs suitable for long-distance running; there are 4 toes on the feet, but the side toes are more degener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com