Method for regulating selective generation of oxidation active matter of iron-based Fenton catalyst

An oxidation activity and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem that active species cannot be selectively controlled, and achieve metal dissolution. Low content, stable structure, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

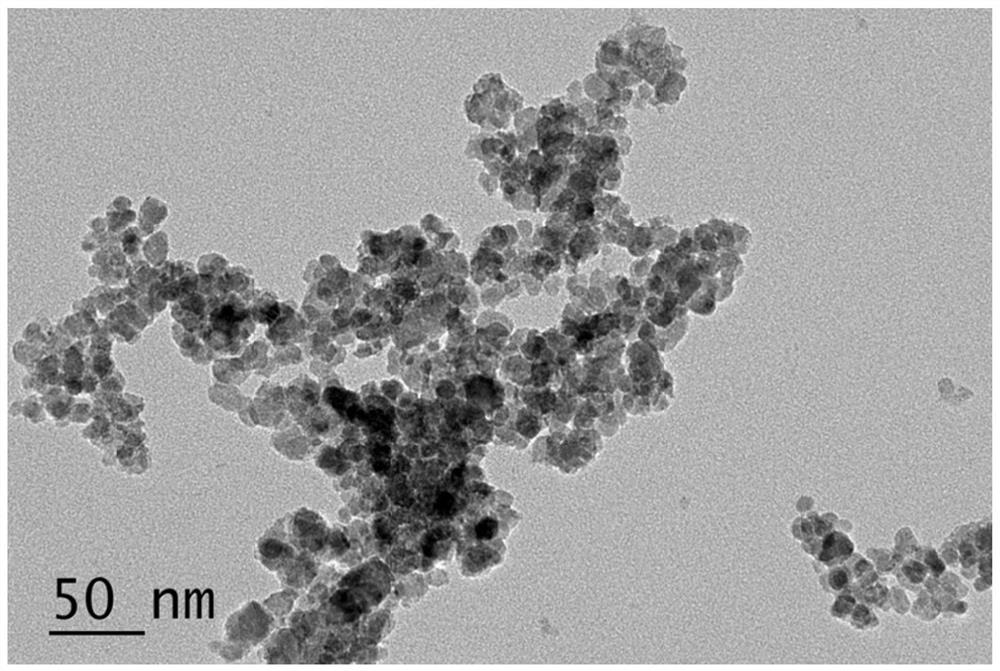

[0049] This embodiment provides a method for regulating the selective generation of oxidation active substances of iron-based Fenton catalysts, wherein the preparation process of iron-based Fenton catalysts is as follows:

[0050] 1) 0.1M Ti(SO 4 ) 2 and 1.0M Fe(ClO 4 ) 3 Dissolved in 10% methanol solution to obtain solution X;

[0051] 2) Add 1.0M NH 4 The OH solution was added dropwise to the solution X, and the mechanical stirring at 300rpm was continuously mixed during the dropping process to obtain a suspension Y with a pH of 7;

[0052] 3) Place the suspension Y in a water bath at 60°C for 300rpm and mechanically stir for 1h, then let stand for 1h;

[0053] 4) Place the suspension Y in a tube furnace with an initial temperature of 60°C and a heating rate of 15°C / min to 300°C for 3 hours;

[0054] 5) The obtained material was washed with deionized water, centrifuged, and vacuum-dried at 50° C. for 12 hours to obtain an iron-based Fenton catalyst.

[0055] In the ir...

Embodiment 2

[0059] This embodiment provides a method for controlling the selective generation of oxidation active substances of iron-based Fenton catalysts, wherein the preparation process of iron-based Fenton catalysts is basically the same as that of Example 1, the difference being: 1) 0.1M Ti(SO 4 ) 2 and 0.5MFe(ClO 4 ) 3 Dissolved into 10% methanol solution to obtain solution X.

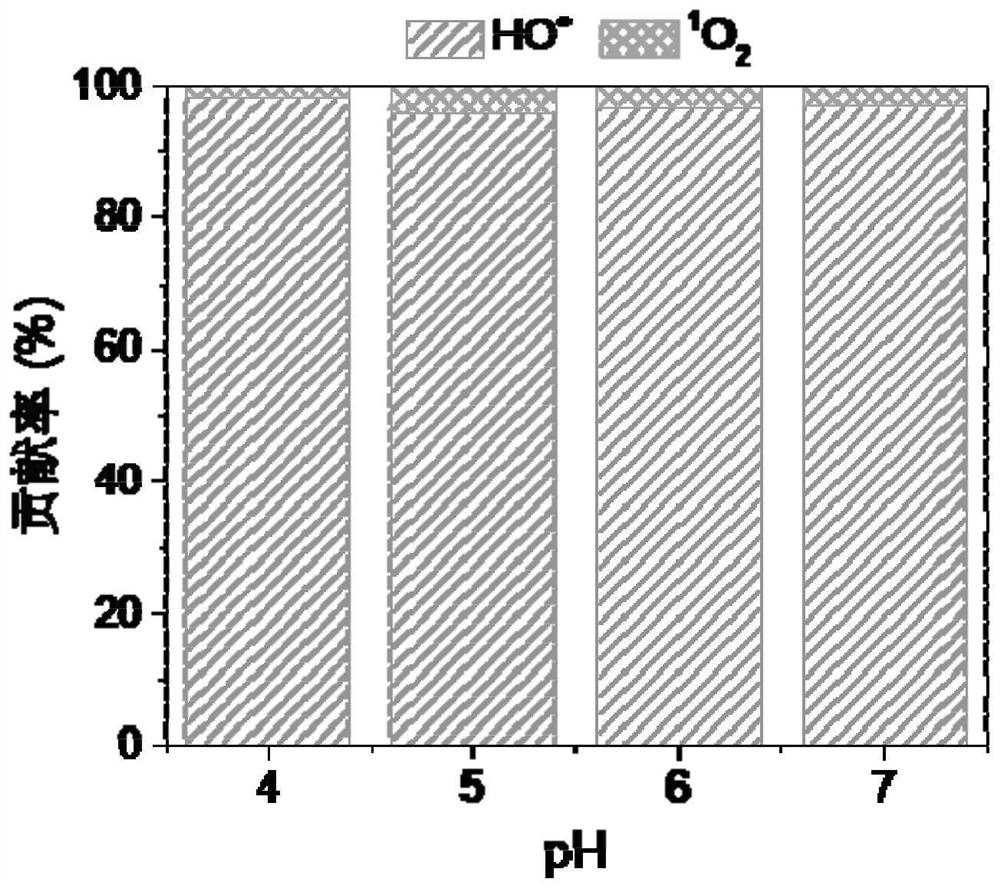

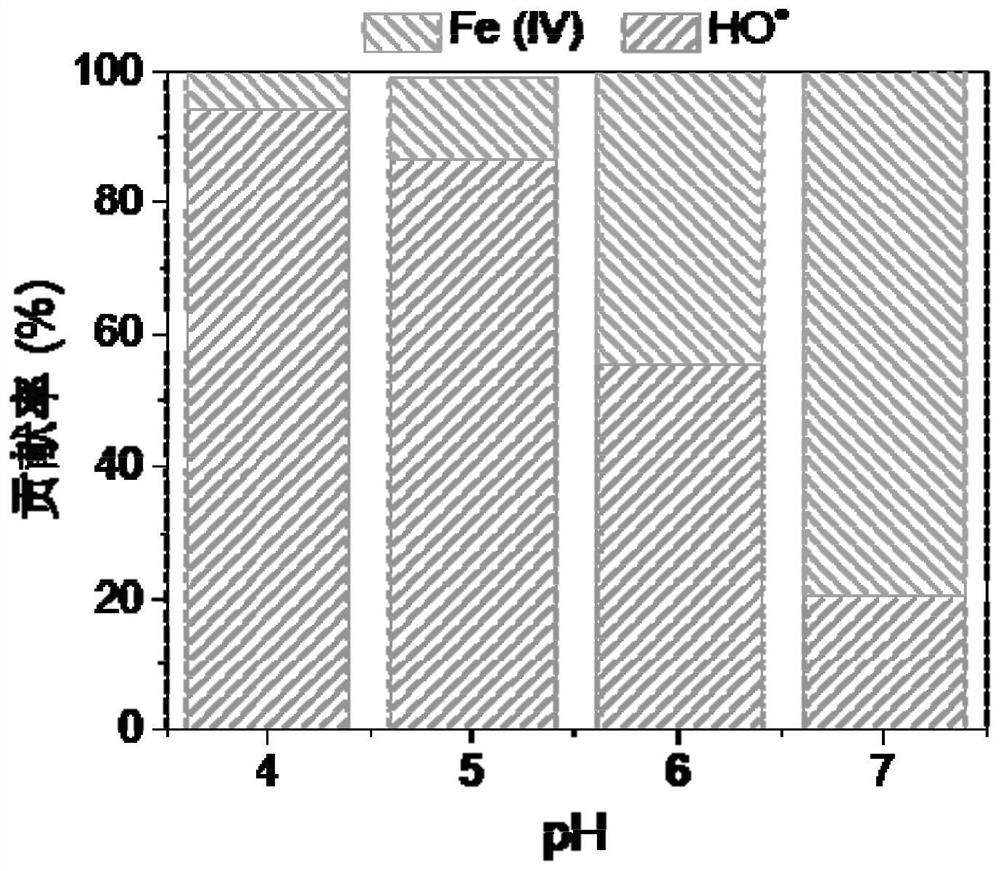

[0060] Therefore, in the iron-based Fenton catalyst of this example, A1 / B1=5:1, and the degradation rate data of bisphenol A are shown in Table 1. image 3 HO in this example · and the contribution rate of Fe(IV) / Fe(V) to the degradation of bisphenol A. The contribution rate of Fe(IV) / Fe(V) in the system reaches 80% at pH=7, indicating that the oxidation active species generated by the catalyst at pH=7 is dominated by Fe(IV) / Fe(V) Contribution, that is, the generated oxidation active species is mainly Fe(IV) / Fe(V), which can be used as a catalyst to catalyze the generation of oxidation active species as...

Embodiment 3

[0062] This embodiment provides a method for controlling the selective generation of oxidation active substances of iron-based Fenton catalysts, wherein the preparation process of iron-based Fenton catalysts is basically the same as that of Example 1, the difference being: 1) 0.1M Ti(SO 4 )2 and 0.1MFe(ClO 4 ) 3 Dissolved into 10% methanol solution to obtain solution X.

[0063] Therefore, in the iron-based Fenton catalyst of this example, A1 / B1=1:1, and the degradation rate data of bisphenol A are shown in Table 1. Figure 4 HO in this example · and the contribution rate of Fe(IV) / Fe(V) to the degradation of bisphenol A. The contribution rate of Fe(IV) / Fe(V) in the system reaches 89% at pH=7, indicating that the oxidation active species generated by this catalyst at pH=7 is mainly played by Fe(IV) / Fe(V) Contribution, that is, the generated oxidation active species is mainly Fe(IV) / Fe(V), which can be used as a catalyst to catalyze the generation of oxidation active specie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com