Band sawing machine with saw blade self-cleaning function

A self-cleaning, band sawing machine technology, applied in the direction of sawing machine, sawing machine accessories, metal sawing equipment, etc., can solve the problem of precision if it is not effective, and achieve simple structure, convenient operation, quality and precision sexually apparent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

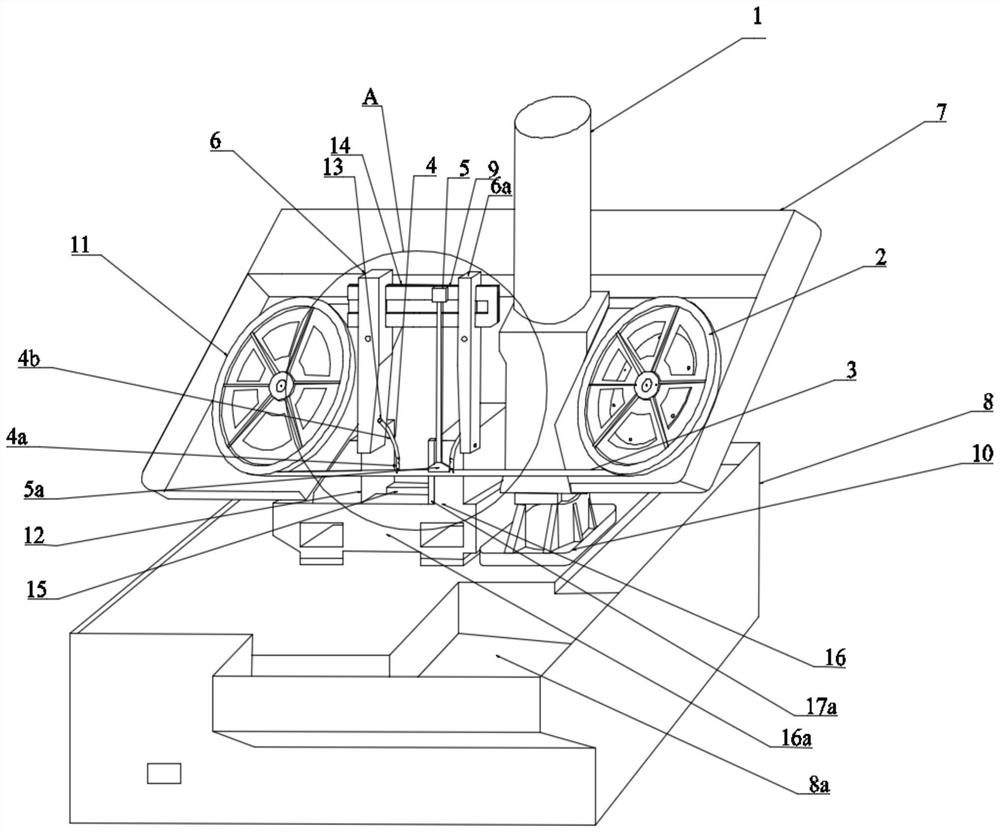

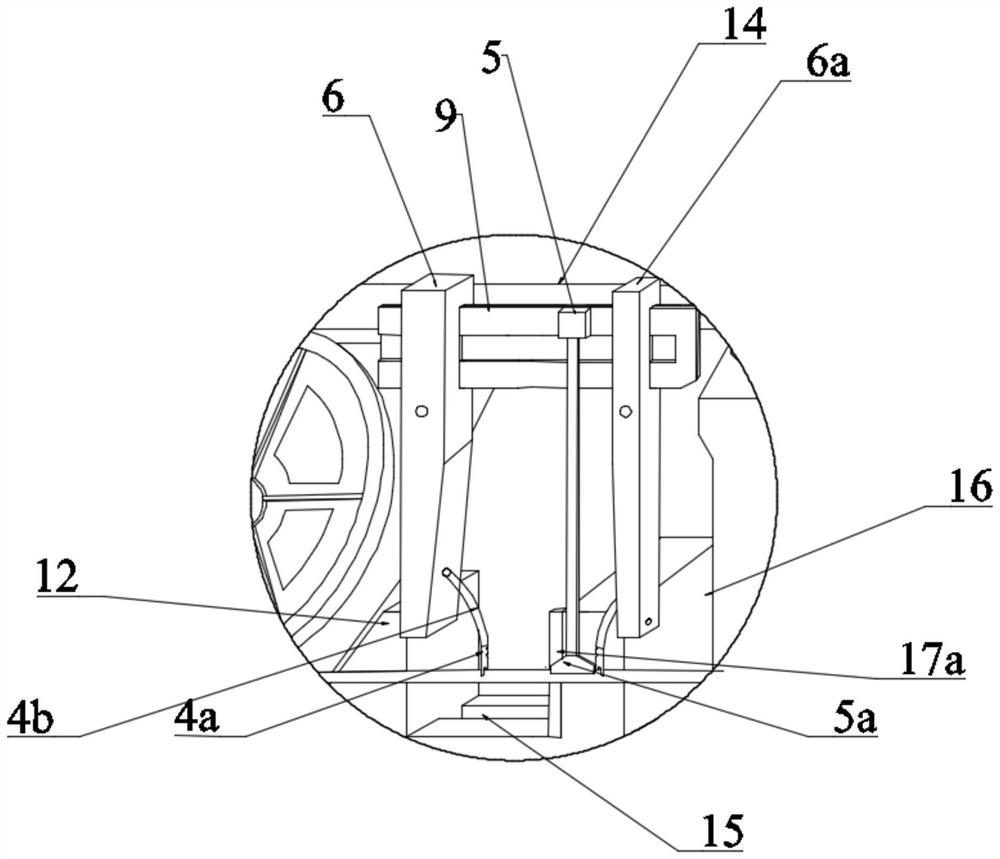

[0024] See Figure 1-6 The present invention provides a technical solution:

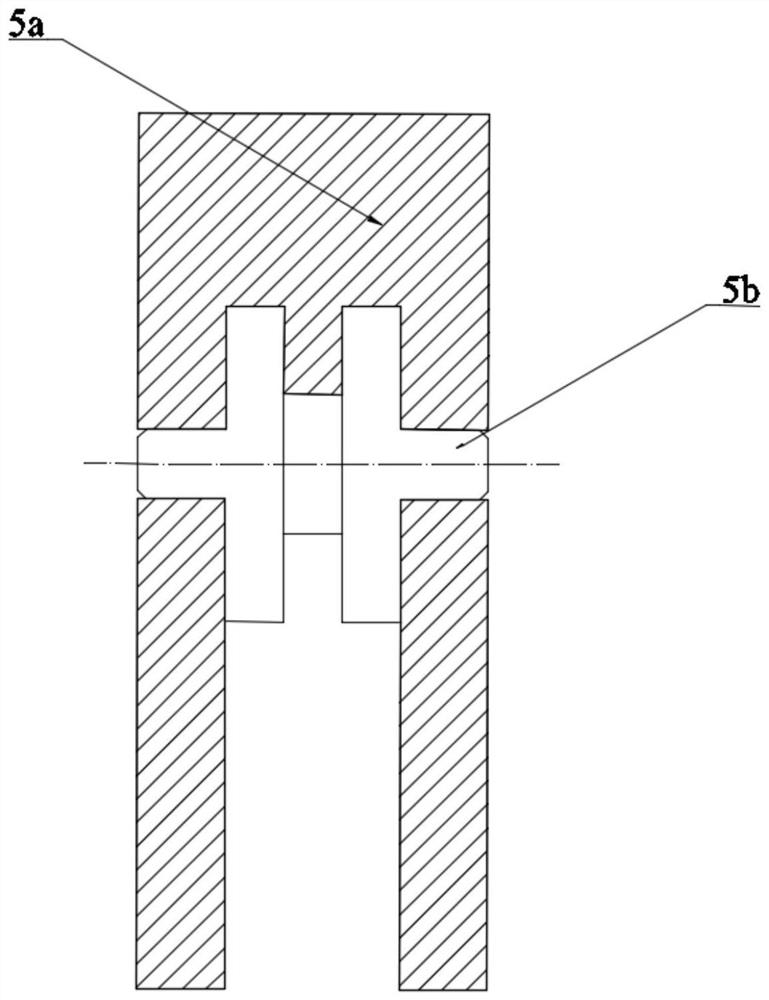

[0025] Such as figure 1 The cutting device includes a substantial cutting structure composed of the drive wheel 2 and the driven wheel 11 and the saw blade 3, and the active wheel and the driven wheel are mounted on the tool holder 7, and the drive wheel 2 rotates the drive power, from The action of supporting and transmission of the wheel, such as Figure 6As indicated, the active wheel 2 and the driven wheel 11 are in the hub end surface of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com