Surface smearing device of carton board printer

A printing press and carton board technology, which is applied in the field of surface coating devices for carton board printing presses, can solve the problems of poor coating effect, decreased glue coating effect, slippage of glue rollers, etc., so as to achieve fast coating effect, improve coating effect, The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

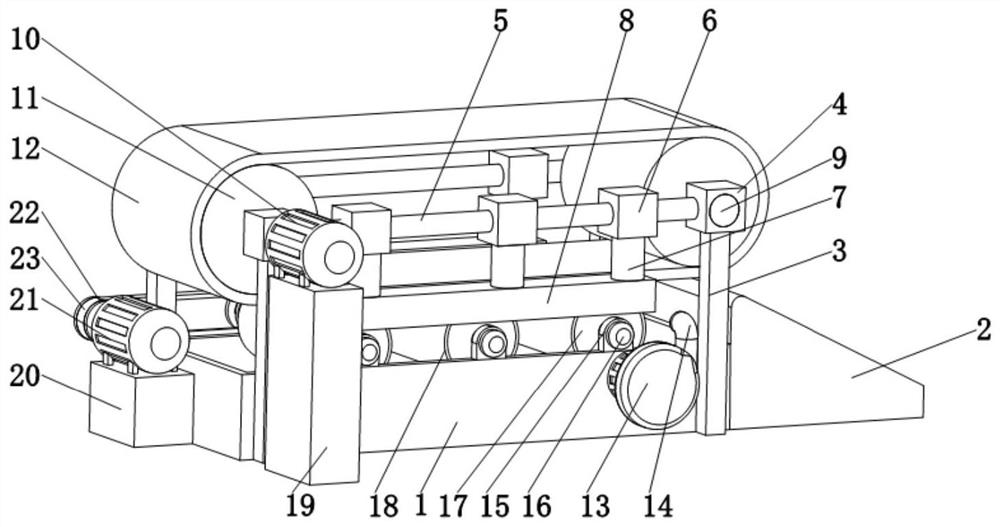

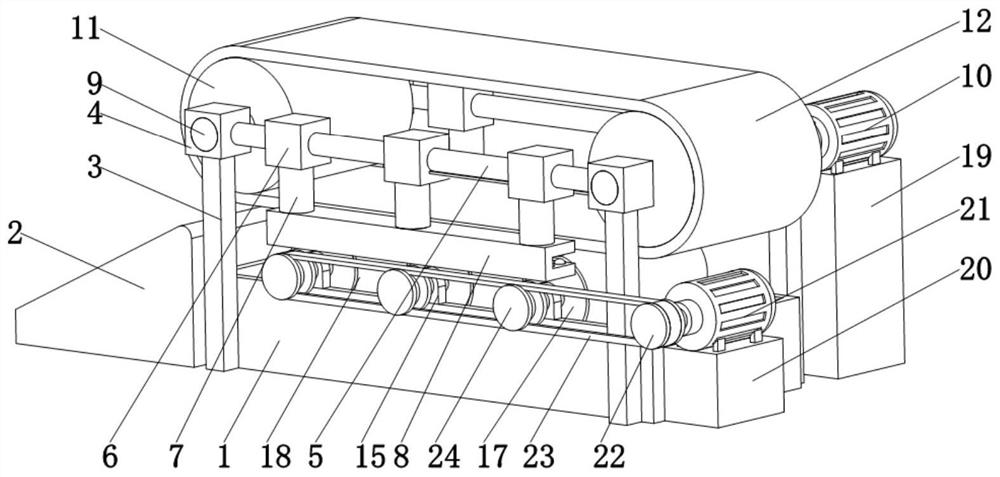

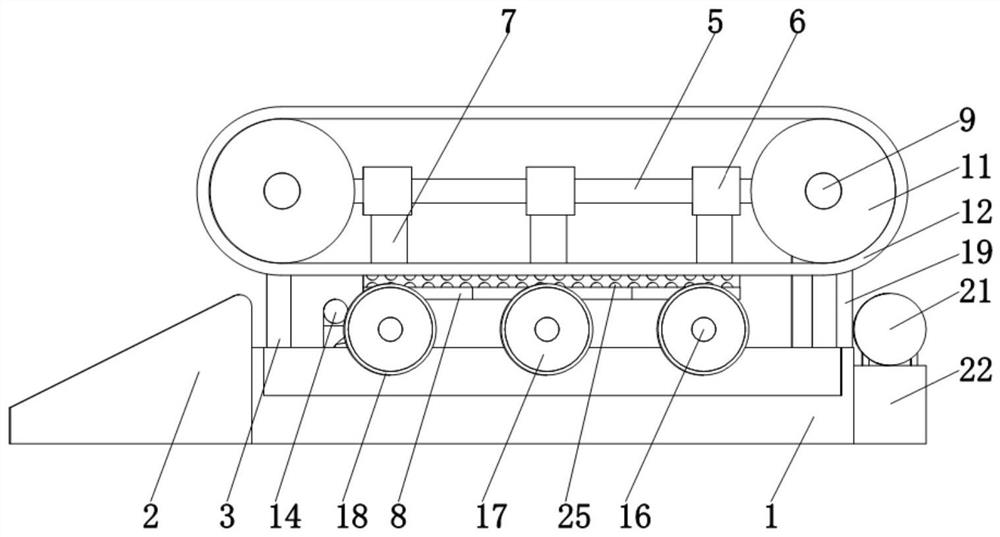

[0029] Such as Figure 1 to Figure 6 As shown, the present invention provides a surface smearing device for a carton board printing machine, comprising a glue tank 1, the right side of the glue tank 1 is fixedly equipped with a feeding port 2, and the left and right ends of the front and rear sides of the glue tank 1 are all fixed. Support frame 3 is installed, and the top of four support frames 3 is fixedly equipped with support block 4, two support frames 3 corresponding to the front and rear sides and support block 4 are a group, and each group of support block 4 is fixedly installed with Cross bar 5, the left and right ends of cross bar 5 outer surfaces all are fixedly installed with fixed block 6, and the bottom of fixed block 6 is fixedly installed with telescopic rod 7, and telescopic rod 7 adopts electric telescopic rod, is convenient to adjust and control;

[0030]The bottom of the telescopic rod 7 is fixedly connected with an auxiliary frame 8, which is used to limit...

Embodiment 2

[0043] Since the surface of the carton board has a certain amount of small pieces of paper sticking to it after production, when the conveyor belt 12 drives the carton board forward through friction for a long time, the upper surface of the conveyor belt 12 is easy to stick to the small pieces of paper and is easily compacted. It causes slipping when driving the carton boards to move, which is not conducive to the normal transmission of the carton boards; and when the roller 17 is in contact with the carton boards for a long time, small paper scraps will stick to the surface and it will easily cause the roller 17 to slip after being compacted. , affecting the uniformity of smearing glue on the carton board. To solve the above problems, such as Figure 7 As shown, a cleaning plate 808 is provided between the balls 25 of the upper frame 801 and the balls of the lower frame 802; The length of the frame 8 is to improve the cleaning effect of the cleaning plate 808 on the conveyor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com