Unmanned aerial vehicle battery reloading platform based on manipulator and reloading method

A technology of manipulators and mobile batteries, which is applied in charging stations, motor vehicles, electric vehicles, etc., can solve the problems of time-consuming and labor-intensive batteries, and achieve the effect of saving manpower and material resources, eliminating time waste, and the process of changing batteries for drones is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

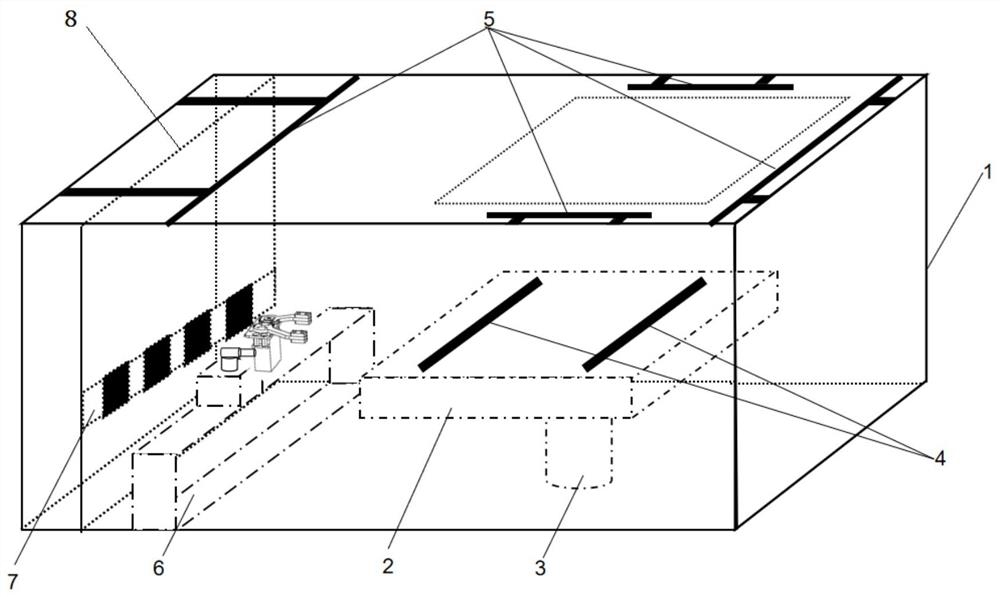

[0039] An unmanned aerial vehicle battery replacement platform, including a control system, a battery replacement inner cabin 1 with a landing opening 8 formed on the top, a biaxial correction device arranged on the landing opening 8, and a battery replacement inner cabin 1 The lifting device, the battery replacement device 6 and the battery management device 7, wherein:

[0040] The biaxial correction device includes four correction rods 5 corresponding to the four sides of the landing opening 8 and four linear drive structures 3 correspondingly driving each correction rod 5;

[0041] The lifting device includes a landing platform 2 for the landing of the drone and a lifting drive structure for driving the landing platform 2;

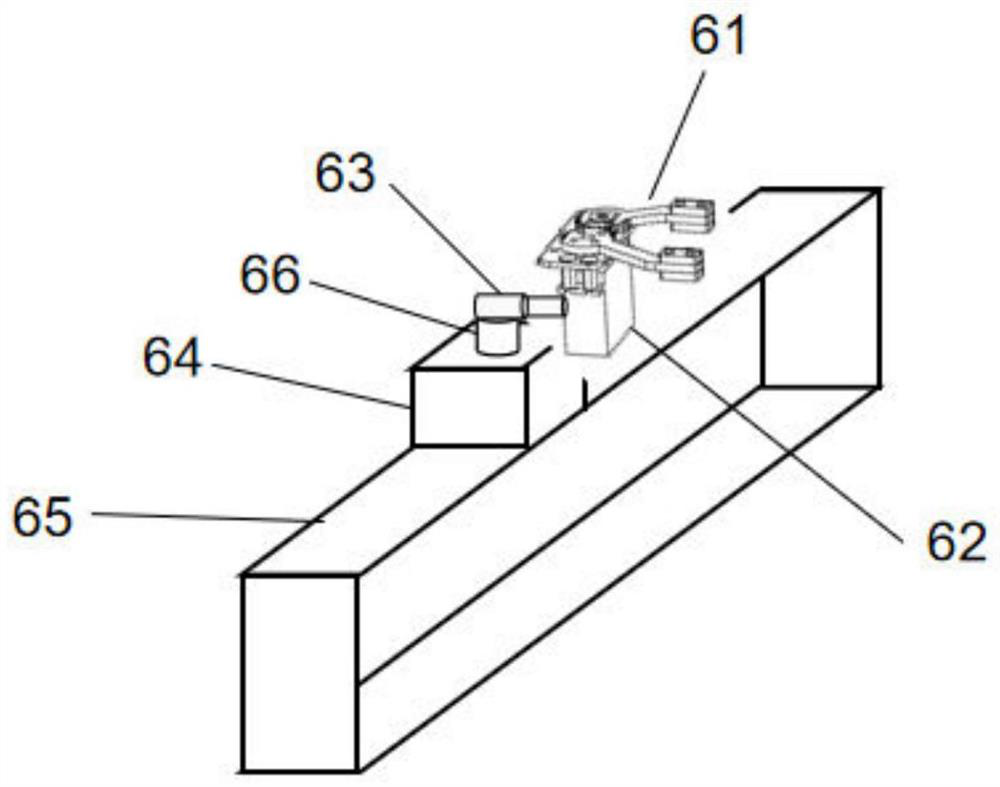

[0042] The lifting device is opposite to the battery management device 7 and is respectively located on both sides of the battery replacement device 6. The battery replacement device 6 includes a Y-axis driving structure, an X-axis driving structure dr...

Embodiment 2

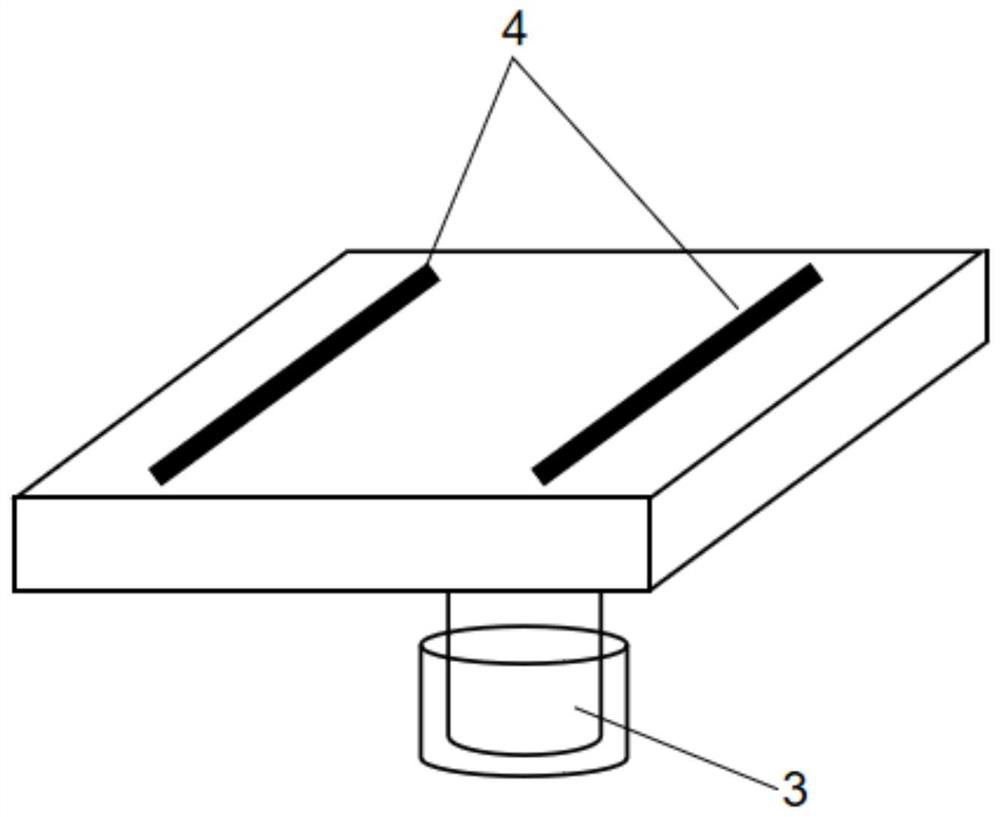

[0053] In order to ensure that the unmanned aerial vehicle lands on the landing platform 2 more accurately, and prevent the unmanned aerial vehicle from following up during the process of disassembling or inserting the battery, two strips are formed on the upper surface of the landing platform 2 to connect with the unmanned aerial vehicle. The corresponding drop grooves 4 of the two bars of the drop frame. The distance between the two landing grooves 4 is the same as the distance between the two bars of the landing gear. The UAV corrects its position under the action of the correction rod 5 until the landing gear at the bottom of the UAV falls into the landing groove 4 to form a positioning .

[0054] More preferably, the inner diameter and length of the landing groove are respectively the same as the thickness and length of the two rods of the landing gear. This ensures that when the UAV is on the landing platform 2, the two rods of the landing gear can be well snapped into ...

Embodiment 3

[0061] In order to ensure the smooth operation of the battery replacement device 6 , two fingers of the manipulator 61 are fixed with a block, and the block can be correspondingly inserted into the slots on both sides of the battery case. Realize the function of fixing the battery when clamping.

[0062] The two sides of the top of the battery shell of the UAV are provided with square card slots, which can be embedded with the blocks of the manipulator, and the bottom of the battery of the UAV is provided with contact electrodes, which can be connected to the rechargeable battery box .

[0063] In order to ensure the smooth operation of this replacement platform, the following is an introduction to each drive structure:

[0064] The linear driving structure 3 is an electric lifting rod, the X-axis driving structure is an X-axis electric push rod 63, and the fixed part of the manipulator 61 is fixed on the driving end of the X-axis electric push rod 63 through a fixed block 62...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com