Method for eliminating heat treatment mixed crystals of W9Cr4V2Mo steel bearing part

A technology of parts and mixed crystals, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of inconspicuousness and improvement of mixed crystals, and achieve the effect of eliminating mixed crystals and improving mixed crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

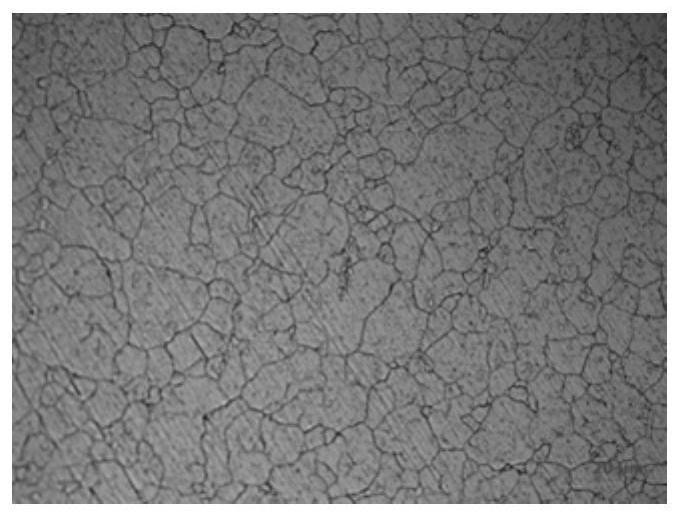

Image

Examples

specific Embodiment approach 1

[0011] Specific implementation mode 1: In this implementation mode, a method for eliminating heat-treated mixed crystals of W9Cr4V2Mo steel bearing parts is specifically carried out according to the following steps:

[0012] W9Cr4V2Mo steel bearing parts need to be annealed before mixed crystals appear after quenching in a vacuum air quenching furnace. The annealing process is: preheating → complete austenitization → primary isothermal → incomplete austenitization → secondary isothermal → cooling .

[0013] The mixed crystal structure of W9Cr4V2Mo steel is caused by structure inheritance or component segregation, so blocking the structure inheritance and further homogenizing the distribution of carbides and alloying elements can eliminate the mixed crystal structure. Therefore, if it is found that there is a mixed crystal structure in the W9Cr4V2Mo steel after heating and quenching, the high temperature and short-time spheroidizing annealing process in this embodiment can grea...

specific Embodiment approach 2

[0015] Embodiment 2: This embodiment differs from Embodiment 1 in that: the annealing equipment is a vacuum air quenching furnace. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0016] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the heating rate from room temperature to the preheating stage is 8°C / min, the preheating temperature is 740-760°C, and the time is 2h. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com