A Method for Improving Wafer Jitter in Tunneling Oxide Growth Process

A tunneling oxide layer and process technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve wafer deformation, affect product silicon chip edge coverage yield, and wafer deformation ISSG process is difficult to solve, etc. problem, to achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

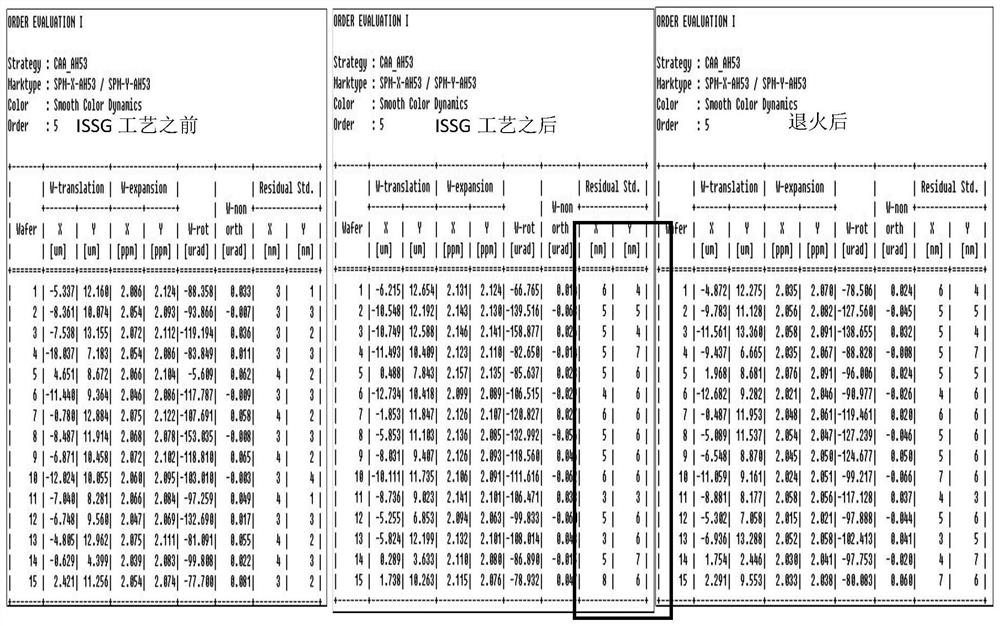

[0034] The invention provides a method for improving wafer shaking in the growth process of the tunnel oxide layer.

[0035] In the following, the present invention will be described in detail and specifically through specific examples, so as to better understand the present invention, but the following examples do not limit the scope of the present invention.

[0036] Such as Figure 8 As shown, a method for improving wafer jitter in the tunnel oxide growth process of the present invention comprises the following steps:

[0037] S1 performing a tunneling oxide layer growth process on a semiconductor substrate;

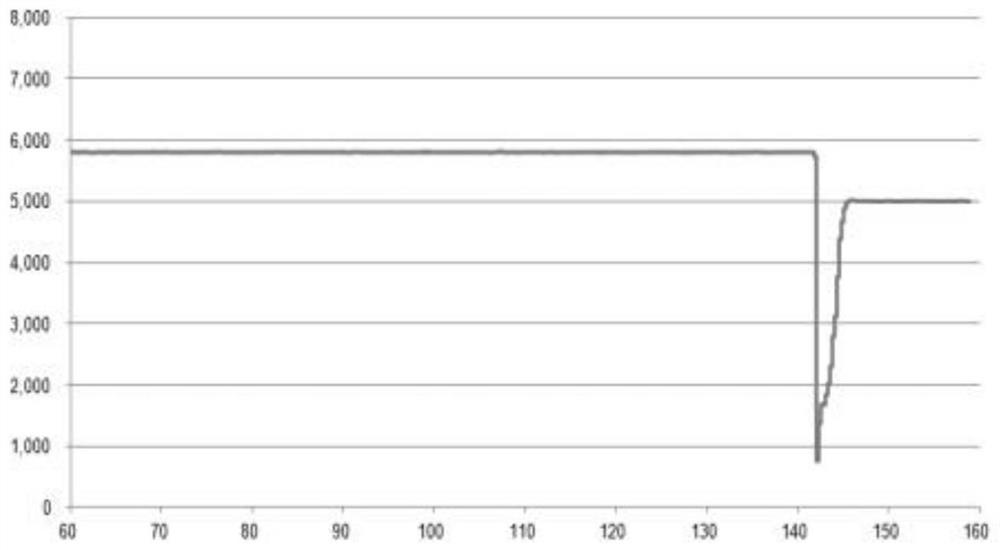

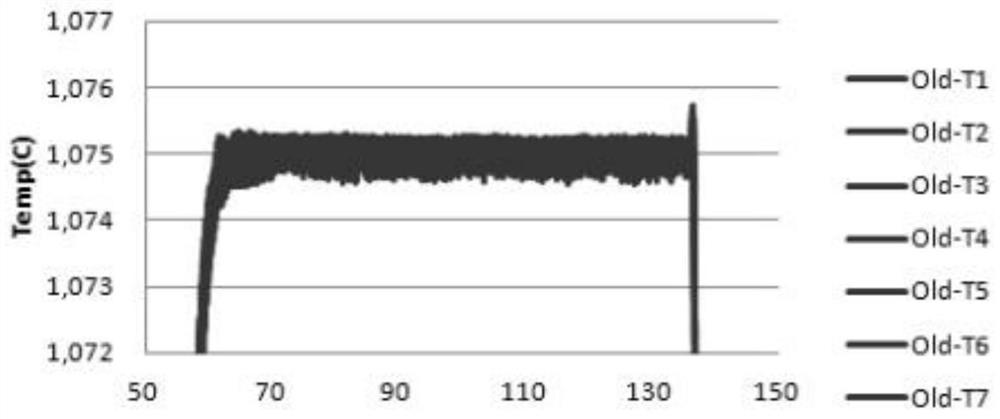

[0038] S2 performing an annealing process on the semiconductor substrate that has undergone the tunneling oxide layer growth process in step S1: heating the reaction chamber, and simultaneously feeding hydrogen and oxygen to keep the pressure in the reaction chamber constant;

[0039] S3 annealing reaction for a certain period of time;

[0040] S4 stops heating the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com