Silicon carbide substrate annealing process and silicon carbide substrate annealing equipment

A technology of silicon carbide substrate and annealing process, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of SiC surface roughening, increasing process time consumption and tape-out cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

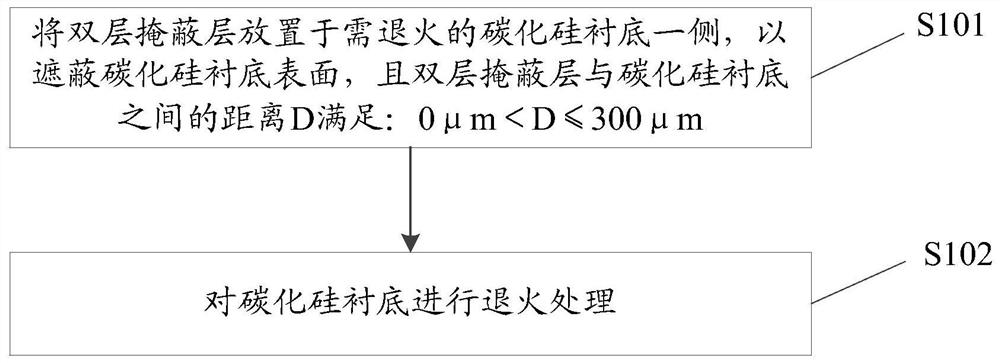

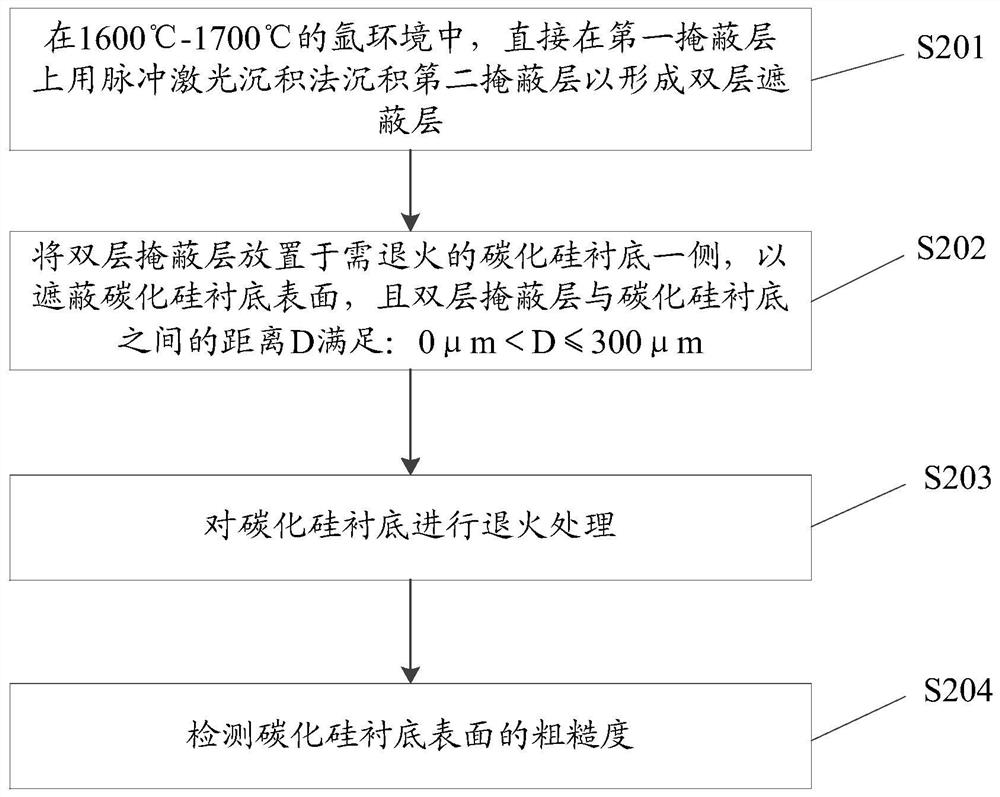

[0032] In order to solve this problem, the industry proposes a solution to the Si atom evaporation phenomenon that occurs during the annealing of p-type (Al ion implantation to SiC to achieve p-type doping) SiC substrate: PLD (pulsed laserdeposition) on the surface of p-type SiC Pulse laser deposition) first deposit a layer of AlN masking layer on the surface of SiC, and then deposit a layer of BN masking layer on the surface of AlN. After annealing, the double masking layer AlN / BN needs to be removed. BN is removed by ion bombardment first, and then AlN is corroded by KOH solution. These two removal steps not only increase the process time, but also increase the tape-out cost. This patent proposes an improved method for SiC annealing AlN / BN double-layer masking, which can not only significantly reduce the time consumption of the process, but also reduce the cost. The following will clearly and completely describe the technical solutions in the embodiments of the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com