Automatic phosphating device and phosphating production process

An automatic and technological technology, applied in the direction of metal material coating process, chemical instruments and methods, cleaning methods and appliances, etc., can solve the problems of low efficiency and labor, so as to improve cleaning efficiency, avoid low efficiency and improve service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

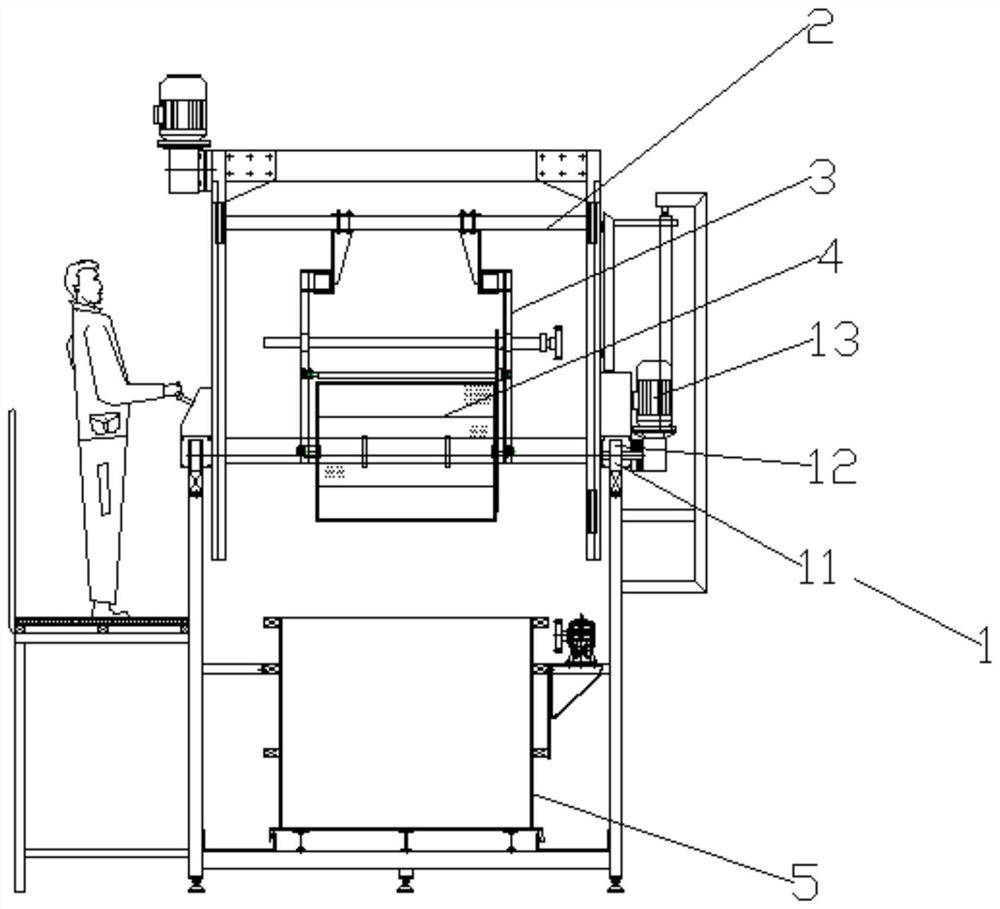

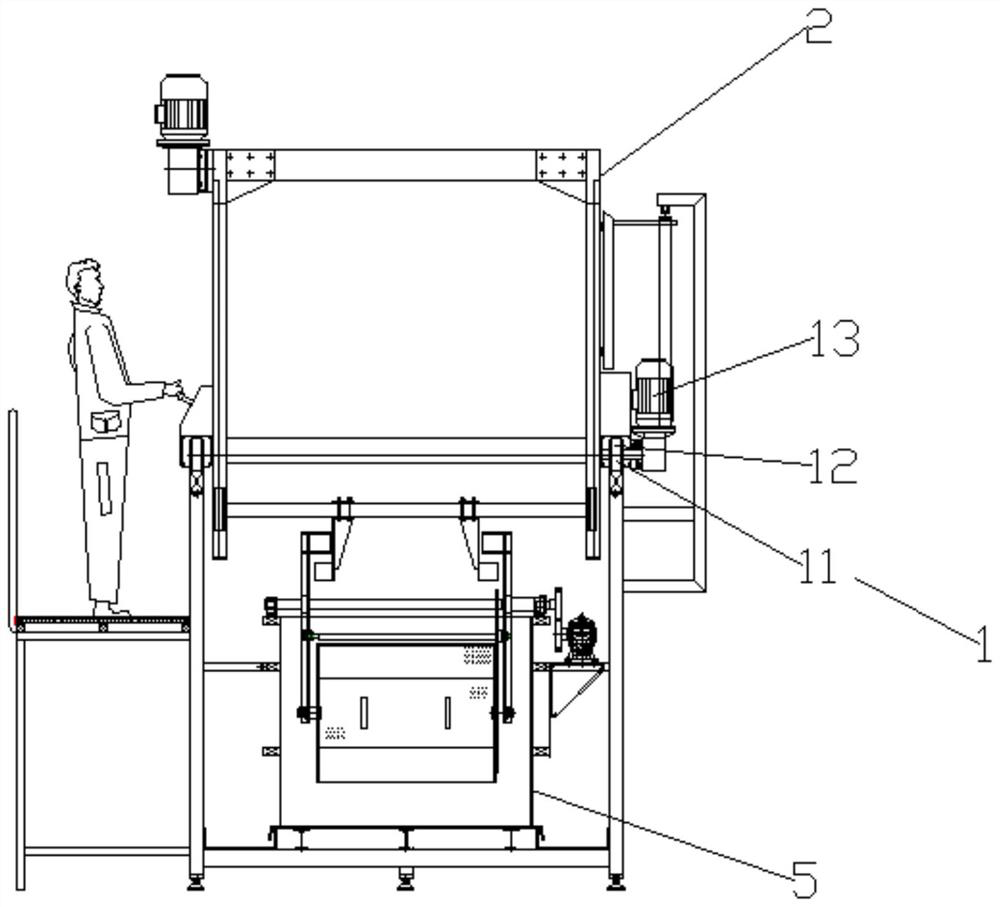

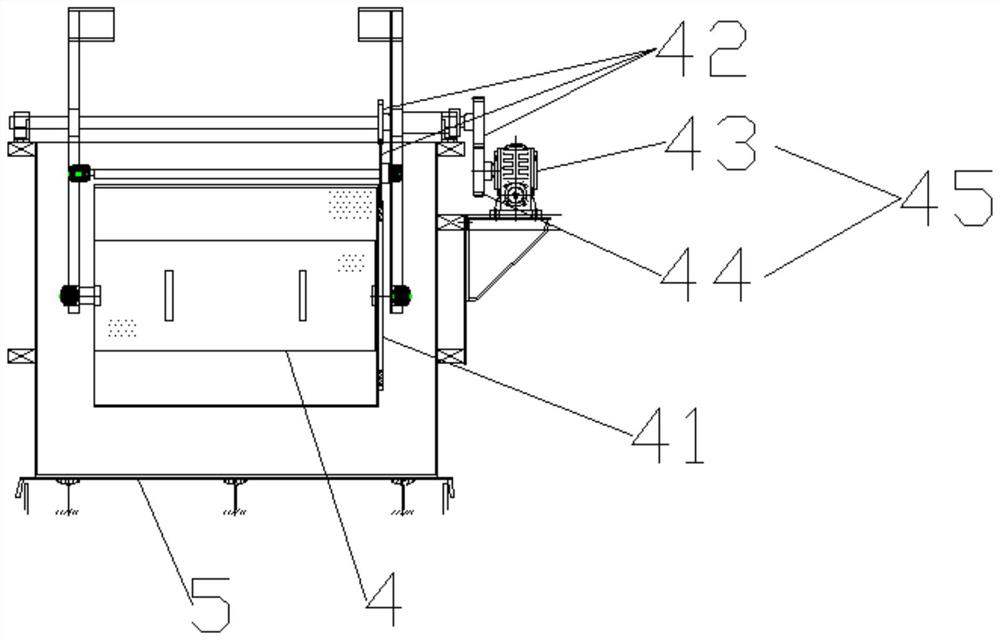

[0050] The automatic phosphating device provided by the present invention includes a horizontal moving mechanism 1, and the horizontal moving mechanism 1 includes a guide rail 11, a slide block 12 and a horizontal drive mechanism 13, the slide block 12 is arranged on the guide rail 11, and the slide The block 12 is connected with the lifting mechanism 2, and the horizontal driving mechanism 13 drives the lifting mechanism 2 to reciprocate on the guide rail 11;

[0051] The bottom of the horizontal moving mechanism 1 is provided with 12 phosphating process pools 5, and the 12 phosphating process pools 5 are connected successively, including the first degreasing pool, the second degreasing pool, the first washing pool, the second washing pool, The exchange tank, the surface adjustment tank, the first phosphating tank, the second phosphating tank, the third phosphating tank, the third washing tank, the hot water cleaning tank and the drying tank are used for degreasing and washing...

Embodiment 2

[0071] The difference between this embodiment 2 and embodiment 1 is that: the lifting mechanism 2 is provided with two groups, and the two groups of lifting mechanisms 2 realize the exchange of the drum frame 3 through the exchange slot. By setting two groups of lifting mechanisms 2, the two groups of lifting mechanisms 2 are responsible for Six phosphating process pools 5 can improve phosphating efficiency.

Embodiment 3

[0073] The difference between this embodiment 3 and embodiment 1 is: the phosphating process tank also includes a pickling tank, a third washing tank and a fourth washing tank;

[0074] Before the clear water washing 2 and the surface adjustment treatment of embodiment 1, the hexagonal drum 4 with the product to be phosphated is moved to the top of the pickling pool by the horizontal moving mechanism 1, and the lifting mechanism 2 will be equipped with the product to be phosphated. The hexagonal drum 4 is put into the pickling pool for derusting treatment, the treatment time is 1min, and then the lifting mechanism 2 will lift the hexagonal drum 4 containing the product to be phosphated;

[0075] Then:

[0076] The horizontal moving mechanism 1 moves the hexagonal drum 4 containing the product to be phosphating to the top of the fourth washing tank, and the lifting mechanism 2 puts the hexagonal drum 4 containing the product to be phosphating into the fourth washing tank for ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com