Method for recovering PGMEA from electronic PGMEA waste solvent

A waste solvent and electronic technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylate, etc., can solve the problems of inability to remove waste solvent photoresist, low purity of PGMEA, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

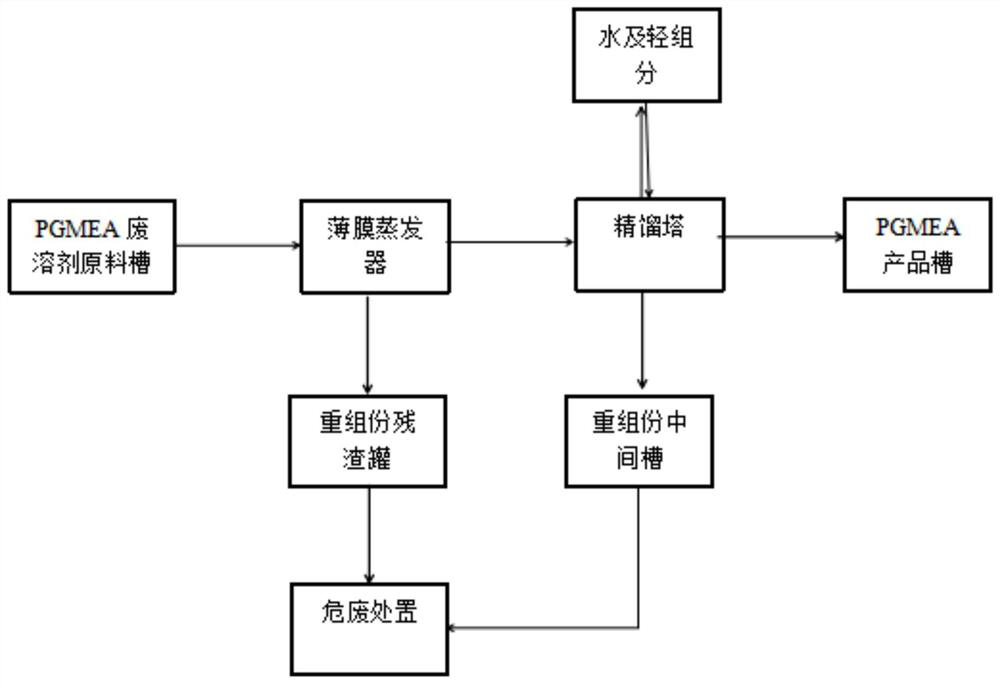

[0040] A method for reclaiming PGMEA from electronic PGMEA waste solvent, comprising the following steps:

[0041] Step 1, weight removal

[0042] Pump the electronic PGMEA waste solvent from the top of the vacuum thin film evaporator, and keep the vacuum inside the thin film evaporator at 5-15KPa. The thin-film evaporator is equipped with a steam jacket, and the electronic PGMEA waste solvent is heated by passing 0.6-0.8MPa steam into the steam jacket. The electronic PGMEA waste solvent will separate the waste solvent gas phase during the heating process, while the photoresist, metal metal salt and other soluble solid impurities in the electronic PGMEA waste solvent will remain in the thin film evaporator.

[0043] A gas phase tube is installed on the top of the thin film evaporator, and the generated waste solvent gas phase is introduced into the condenser, and after condensation, the PGMEA semi-finished product is formed (keep the condensed PGMEA semi-finished product at 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com