Patents

Literature

45 results about "Stoddard solvent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

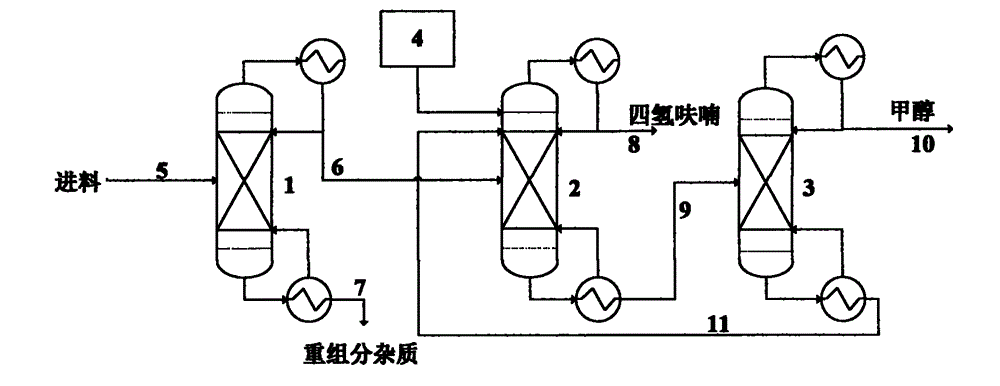

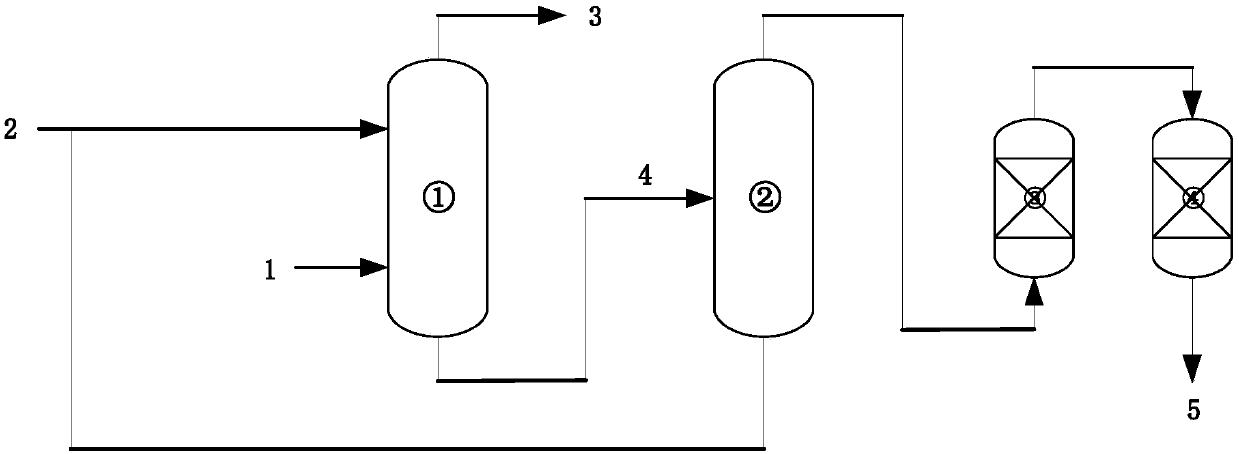

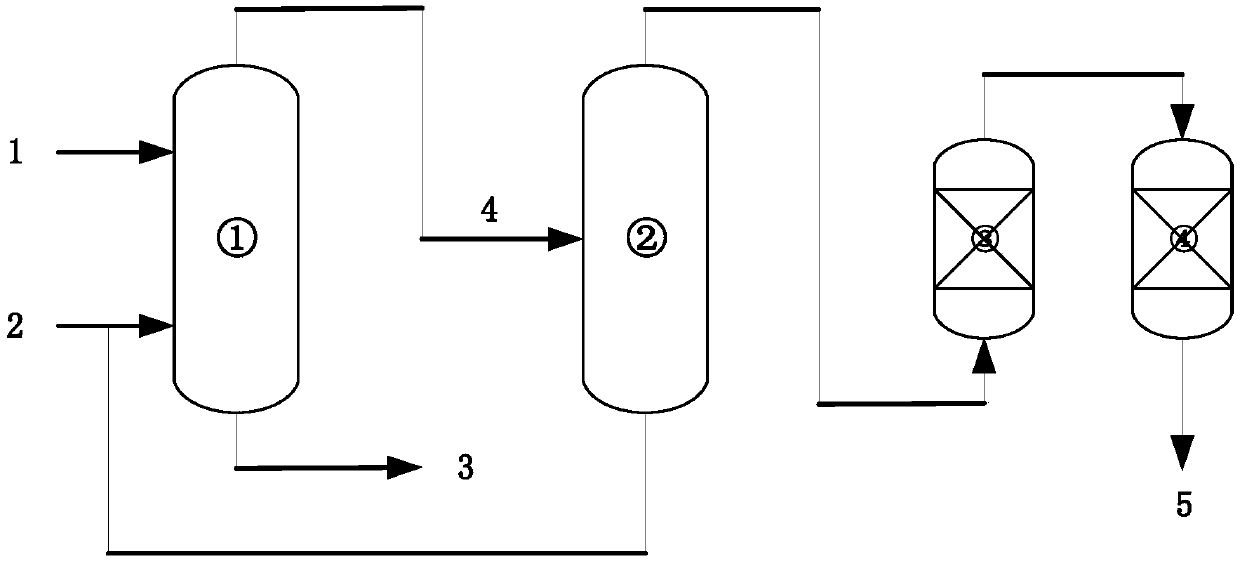

Recovery and separation method for solvent containing tetrahydrofuran-carbinol system

InactiveCN102911139AOrganic compound preparationHydroxy compound preparationLiquid wasteBoiling point

The invention relates to an extraction, rectification and separation method and an extraction, rectification and separation process for a solvent containing a tetrahydrofuran-carbinol system which take ethylene glycol as an extractions solvent, and take tetrahydrofuran and carbinol as products. In the drug synthesis process in the pharmaceutical industry, a great quantity of solvents containing the tetrahydrofuran, the carbinol and the like are used, and a mixed liquid waste is generated. Under the normal temperature and normal pressure, the boiling temperatures of the tetrahydrofuran and the carbinol are extremely similar (the boiling temperature of the tetrahydrofuran is 65.4 DEG C and the boiling temperature of the carbinol is 64.8 DEG C), so that the tetrahydrofuran and the carbinol are difficult to separate by adopting a common rectification operation. In addition, the tetrahydrofuran and the carbinol are good in intersolubility and can be well dissolved with great majority of organic or inorganic solvents so as to be incapable of being separated by an extraction operation. According to the method and the process, the waste solvent containing the tetrahydrofuran-carbinol system can be recovered by adopting an extraction and rectification manner, meanwhile, an extracting agent is recycled, so that the obtained tetrahydrofuran and carbinol products are high in purity, impurities are few, the recovered solvent can be recycled in the drug synthesis process, further not only is the cost of pharmacy process reduced, and also the pollution of the waste solvent to the environment is alleviated greatly.

Owner:EAST CHINA UNIV OF SCI & TECH

Process for separating tert-butyl acetate in medicine waste solvent through vacuum rectification by using super-gravity bed

InactiveCN107827750AReduce manufacturing costImprove recycling ratesOrganic compound preparationVacuum distillation separationAcetic acidReflux

The invention relates to a vacuum rectification method using a super-gravity bed as core separating equipment, and discloses a process for separating and recycling a waste solvent in the synthetic process of statins or other medicines and recovering tert-butyl acetate in the solvent. During operation, the waste solvent enters from a place located between the two-layer and three-layer rotors of thesuper-gravity bed, wherein the rotating speed is 1000r / min, the reflux ratio is 4-10, the vacuum degree at the top of a tower is 20kPa-70kPa, and the temperature of a tower kettle is controlled at 70DEG C-85 DEG C, a tert-butyl acetate product with higher purity can be recovered in the tower kettle, the purity can reach 95% or more, the residual amount of isoprene is less than 1%, and the moisture content is less than 1000ppm, thereby fully meeting the requirements of recycling; and compared with traditional tower-type rectification operation, the process provided by the invention has the advantages of having a simple technological procedure, low energy consumption, a small occupied area of equipment, and high recovery rate of the product tert-butyl acetate, and being capable of effectively improving economic benefits.

Owner:南京揽博环境技术有限公司 +1

Method for recovering tetrahydrofuran from waste solvent

The invention relates to the technical field of purification and recovery of hazardous waste solvents, in particular to a method for purifying and recovering tetrahydrofuran, and particularly relates to a method for recovering tetrahydrofuran from a waste solvent. The method comprises the following steps: preheating raw materials, feeding the preheated raw materials into a normal-pressure rectifying tower taking ethylene glycol as an extracting agent, obtaining an azeotrope of tetrahydrofuran and methanol at the tower top of the normal-pressure rectifying tower, and obtaining a product which is a mixture of water, methanol and ethylene glycol in a tower kettle. The mixture enters an extraction agent recovery tower, and the extraction agent is recovered and recycled. The azeotrope enters a high-pressure tower, tetrahydrofuran with relatively high purity is obtained at a tower kettle, azeotrope containing a small amount of tetrahydrofuran and methanol is obtained at the top of the high-pressure rectifying tower, and the azeotrope at the top of the high-pressure rectifying tower is sent to normal-pressure extractive distillation for circular distillation, so that the product recovery rate is increased.

Owner:JIANGSU YINGTIAN CHEM

Waste solvent treatment method

ActiveCN111747856AImprove protectionEmission reductionOrganic compound preparationHydroxy compound preparationDistillationProcess engineering

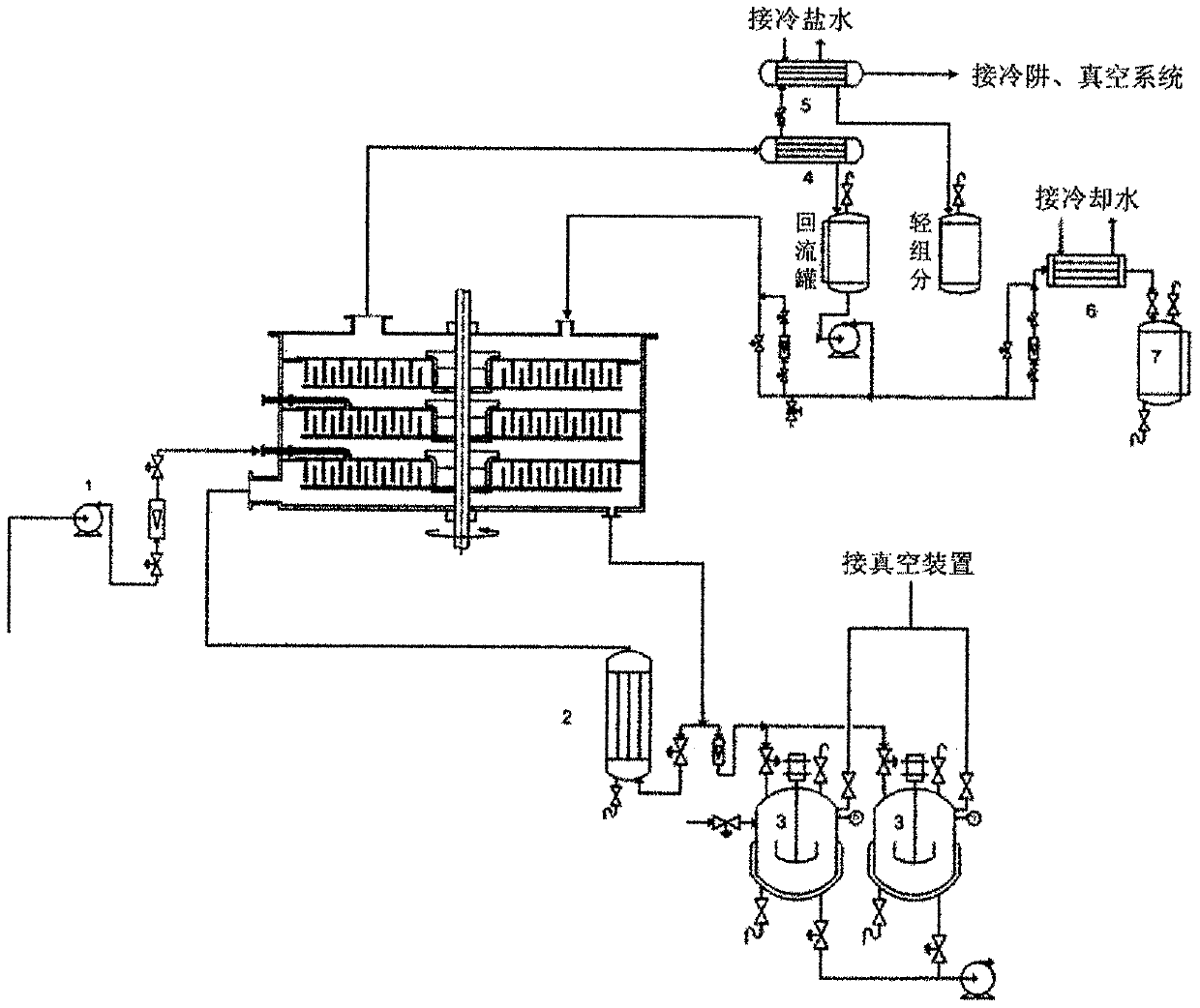

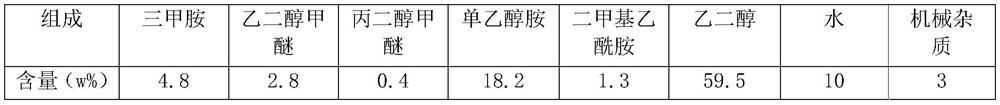

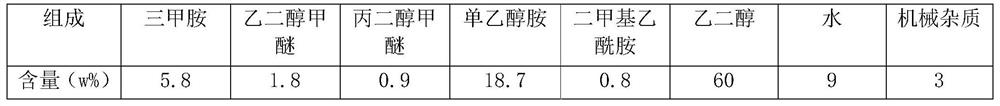

The invention relates to the field of waste liquid treatment, and discloses a waste solvent treatment method. The method comprises the following steps that: (1) reduced pressure distillation is performed, specifically, a cleaned waste solvent is introduced into an evaporator for reduced pressure distillation, after the steam of the waste solvent passes through the top of the evaporator, liquid enters a solvent receiving intermediate tank; (2) drying and recycling are performed, specifically, solid-liquid mixed impurities are : introduced into a dryer for heating, so that a gas-phase part of the solvent flows into the solvent receiving intermediate tank after being condensed; (3) primary reduced pressure rectification is performed, specifically, the solvent in the solvent receiving intermediate tank is introduced into a rectifying tower I, light component impurities are extracted from the tower top of the rectifying tower I, and a product mixture is extracted from the tower kettle of the rectifying tower I; and (4) secondary reduced pressure rectification is performed, specifically, the product mixture is introduced into a rectifying tower II, monoethanolamine is extracted from thetower top of the rectifying tower II, and ethylene glycol is extracted from the tower kettle of the rectifying tower II. With the method adopted, the problem that valuable components in the waste solvent are wasted due to the fact that the waste solvent is treated in an incineration mode in the prior art can be solved.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

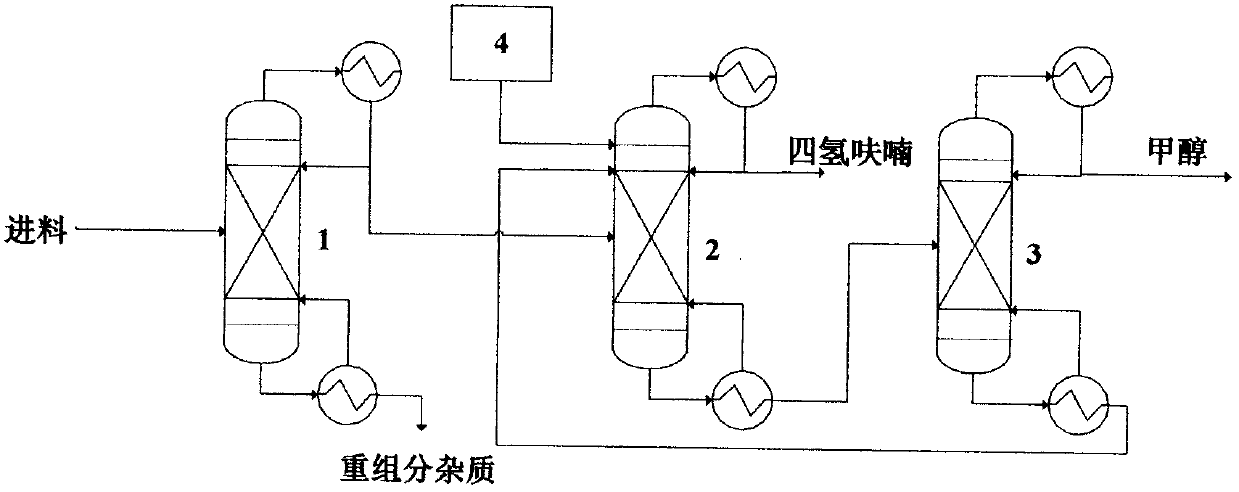

Tetrahydrofuran-methanol system-contained solvent recovering and separating method

InactiveCN107903223AOrganic compound preparationHydroxy compound preparationPharmaceutical SubstancesGlycol synthesis

The invention relates to a method and process for solvent extraction, rectification and separation of a tetrahydrofuran-methanol system using ethylene glycol as an extraction agent and tetrahydrofuran and methanol as products. Generally, pharmaceutical companies use a large amount of solvents such as tetrahydrofuran and methanol in the production process of pharmaceutical products, resulting in mixed waste liquid of solvents. Under normal temperature and pressure, the boiling points of tetrahydrofuran and methanol are very close (65.4°C for tetrahydrofuran and 64.8°C for methanol), so it is difficult to separate them by general rectification. In addition, tetrahydrofuran and methanol have good mutual solubility, and can be well miscible with most organic or inorganic solvents, so it is impossible to separate them by extraction. The present invention adopts the way of extraction and rectification to recover the waste solvent containing tetrahydrofuran and methanol system, and at the same time, the extractant is recycled, and the obtained tetrahydrofuran and methanol products have high purity and less impurities, and can be used for solvent recycling in pharmaceutical companies. It not only reduces the cost of the pharmaceutical process, but also greatly reduces the pollution of the waste solvent to the environment.

Owner:南京科慧化工技术服务有限公司

A method for purifying pgmea from pgmea waste liquid

ActiveCN104370742BReduce consumptionHigh recovery rateOrganic compound preparationCarboxylic acid esters separation/purificationDistillationKetone

The present invention disclosed a method of purifying PGMEA from PGMEA waste liquid. PGMEA waste liquid mainly contains PGME (propylene glycol methar ether), ketone compounds, benzene compounds, ethyl ester compounds, methoxycodes, and compounds, and methamphetamine.Water, solid resistance, electronic component and other impurities, the scope and content of waste liquids and content changes are widely changed. The PGMEA waste liquid generated by the invention for the electronic industry is initially filtered for the collected waste solvents.Impurities, after the settlement, the upper liquid enters the distilled tower with vacuum pumps to remove the low -boiling point and high boiling point impurities that are difficult to handle. The target products generated by the distilled tower enter the psychiatric tower to further distille, obtaining target products with a purity of more than 95%The maximum purity can reach 99%.The processing equipment mainly includes filter, sinking kettle, distillation tower, and distillation tower.

Owner:惠州TCL环境科技有限公司

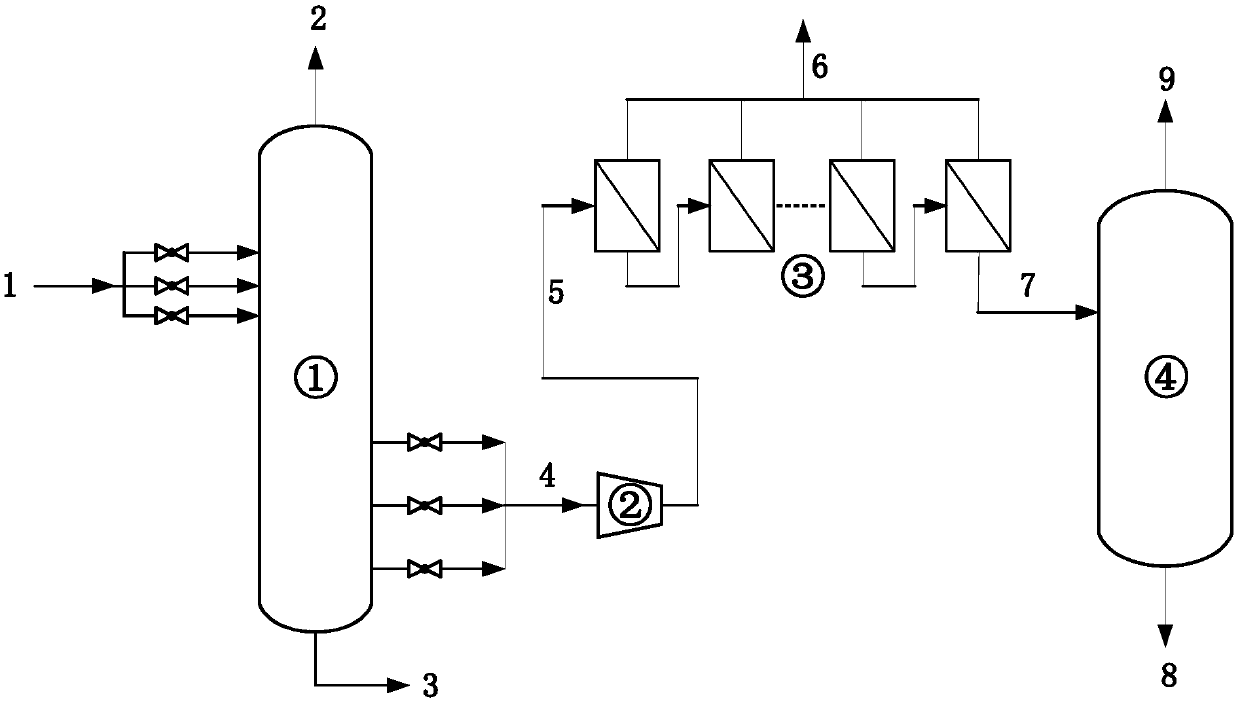

Recovery method of N, N-dimethylacetamide

PendingCN111100027AComply with solvent application requirementsSimple processCarboxylic acid amide separation/purificationDistillationProcess engineering

The invention provides a recovery method of N, N-dimethylacetamide. The method comprises the following steps: enabling a waste solvent to enter a distillation tower, carrying out side line gas phase extraction, pressurizing, directly introducing an obtained product into a membrane separation unit, and dehydrating, so as to obtain an N, N-dimethylacetamide product. According to the invention, through a distillation tower side line gas phase extraction and membrane separation coupling mode, the process is simplified, the process energy consumption is reduced, especially the material heating process before membrane separation is saved, the process is green, the reuse rate is high, the waste discharge amount is small, and the industrialization is favorably realized. Meanwhile, the product purity of the obtained N, N-dimethylacetamide is higher than 99.9%, the moisture content is lower than 200 ppm, and the requirement for solvent application is completely met.

Owner:CHINA PETROLEUM & CHEM CORP +1

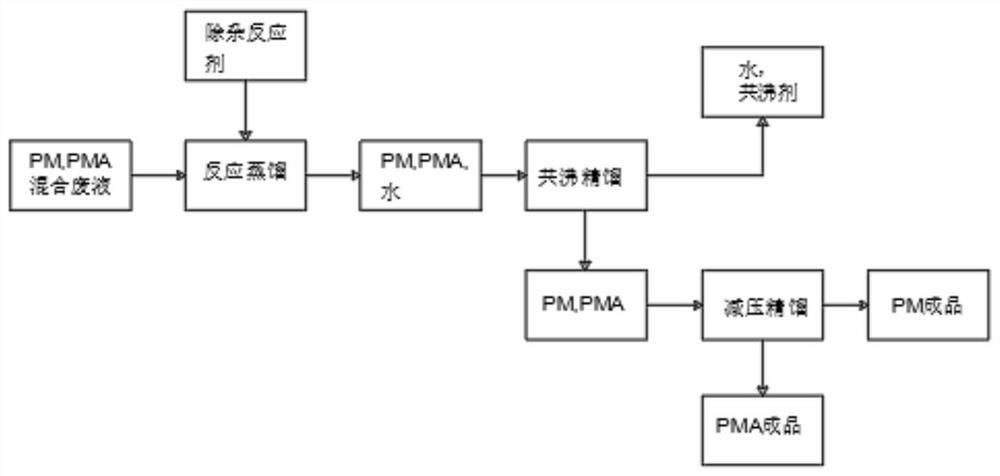

Method for recovering and purifying propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate from electronic waste liquid

InactiveCN113527072AEnable recyclingReduce pollutionEther separation/purificationOrganic compound preparationMonomethyl etherOrganic solvent

The invention discloses a method for recovering and purifying propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate from electronic waste liquid, and relates to the field of solvent recovery and purification. The method comprises the following steps: S1, taking mixed waste solvents propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate, adding an impurity removal reactant, and carrying out reaction through a mixing mechanism to remove impurities and other impurities; S2, adding the mixed solution of propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate into an organic solvent which forms azeotropy with water, distilling at the temperature lower than the boiling point of propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate, distilling out water and an entrainer, and reserving a mixture of propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate; and S3, obtaining an entrainer water azeotrope at the tower top. According to the method, the waste propylene glycol monomethyl ether and propylene glycol monomethyl ether acetate are recycled, the pollution degree of the waste solvent generated in electronic production to the environment is reduced, and the production cost is reduced.

Owner:四川熔增环保科技有限公司

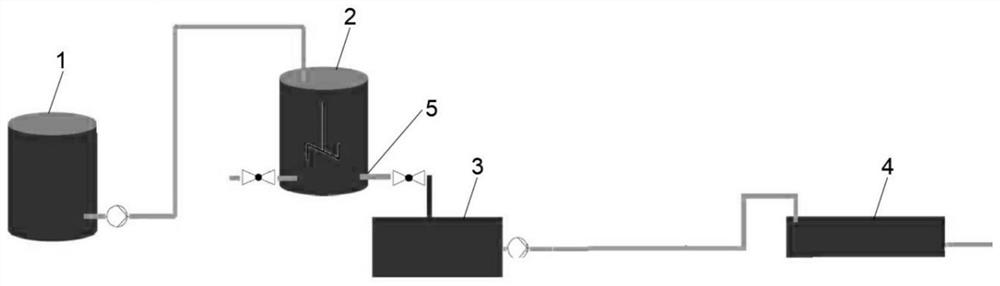

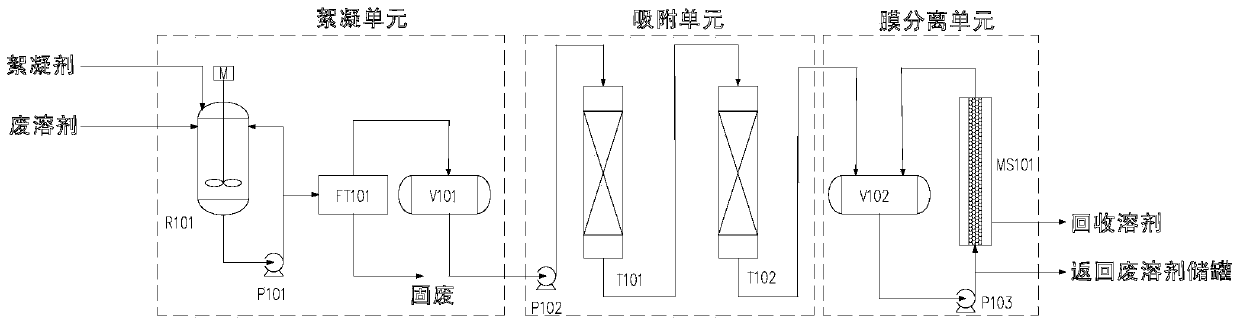

Recycling method of coating water-based colored paint waste solvent

The invention discloses a recycling method of a coating water-based colored paint waste solvent. The method comprises the following steps: adding a colored paint waste solvent into a reaction kettle (R101), adding a flocculant water solution into the reaction kettle (R101), sufficiently stirring, conveying to a filter (FT101), filtering out flocculated solid impurities, and feeding the clear liquid into a clear liquid tank (V101); sequentially conveying the clear liquid in the clear liquid tank (V101) to a primary adsorption tower (T101) and a secondary adsorption tower (T102), feeding the treated material into a mother liquid tank (V102), then feeding into a membrane separation device (MS101), filtering, extracting the filtrate obtained after filtering as a recovered solvent, and returning the recycled solvent to the mother liquid tank (V102). According to the invention, the recovery rate of the effective component in the colored paint waste solvent is greater than or equal to 85%, the hazardous waste decrement is greater than or equal to 85%, and the recovered solvent can be used for on-site robot color-changing cleaning and other related cleaning after a small amount of primarycolor paint cleaning agent is supplemented.

Owner:天津净润环保科技有限公司

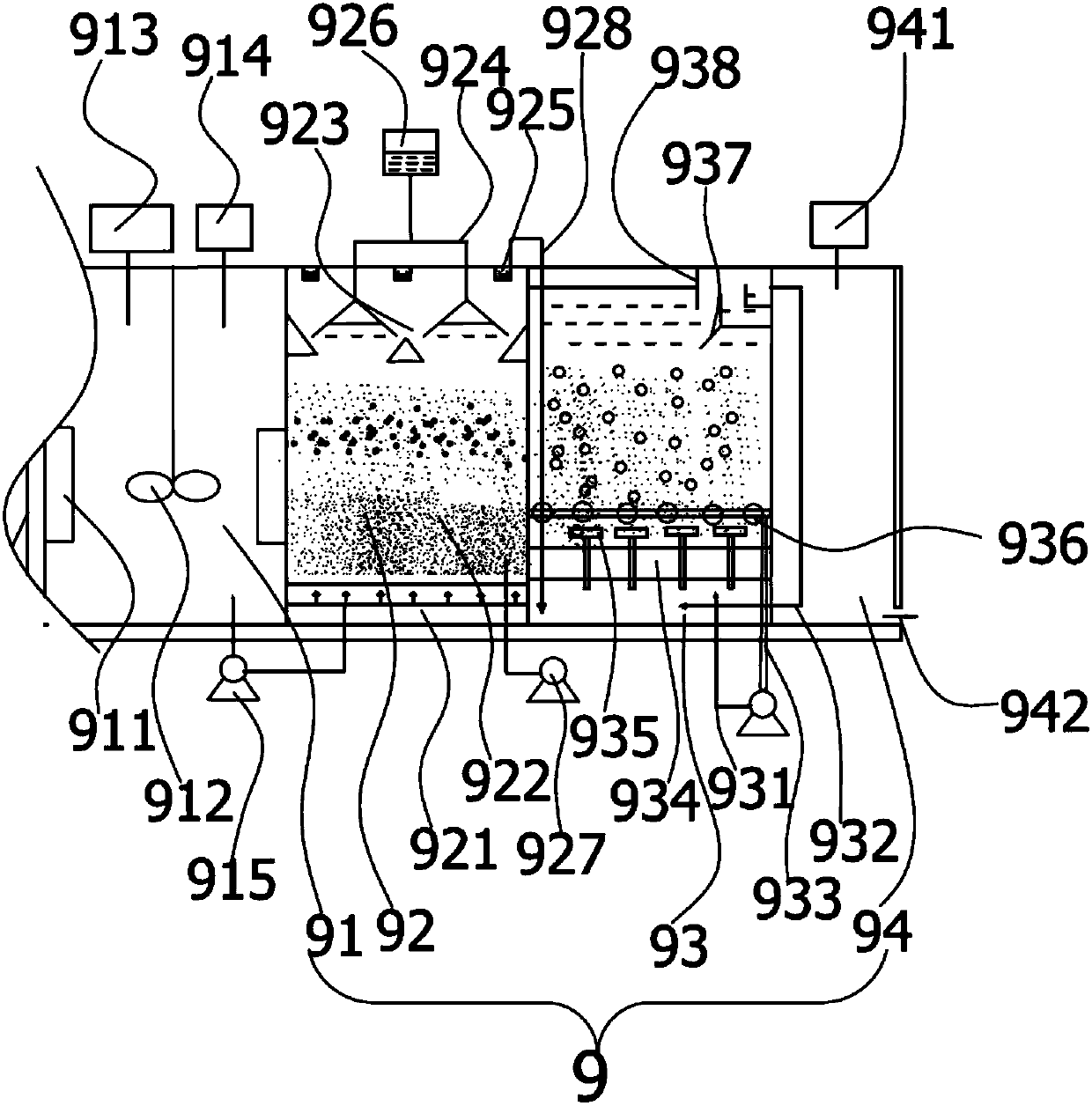

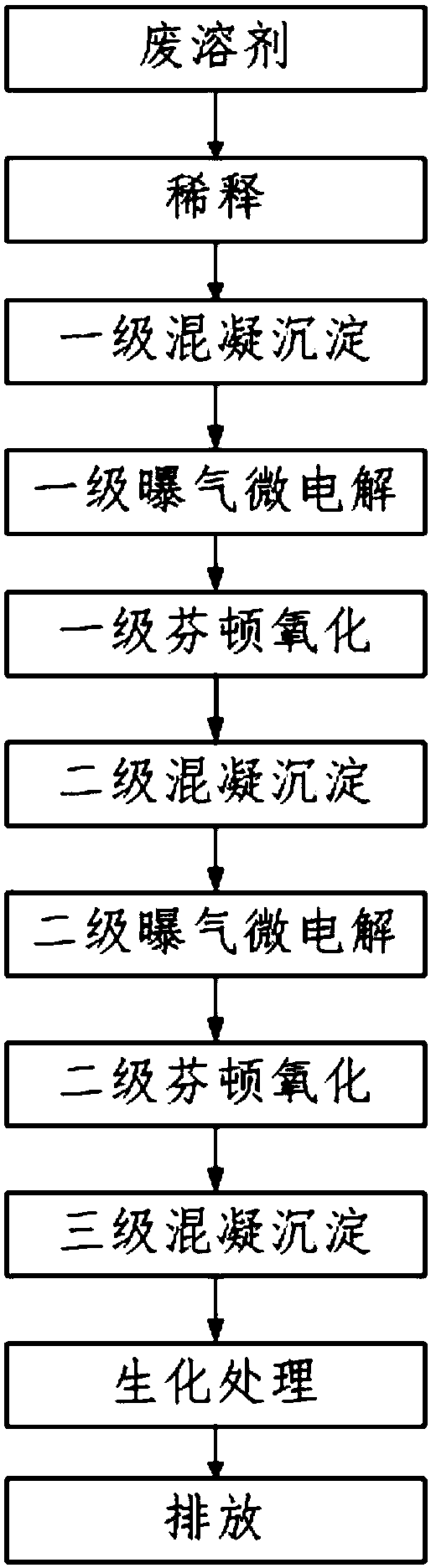

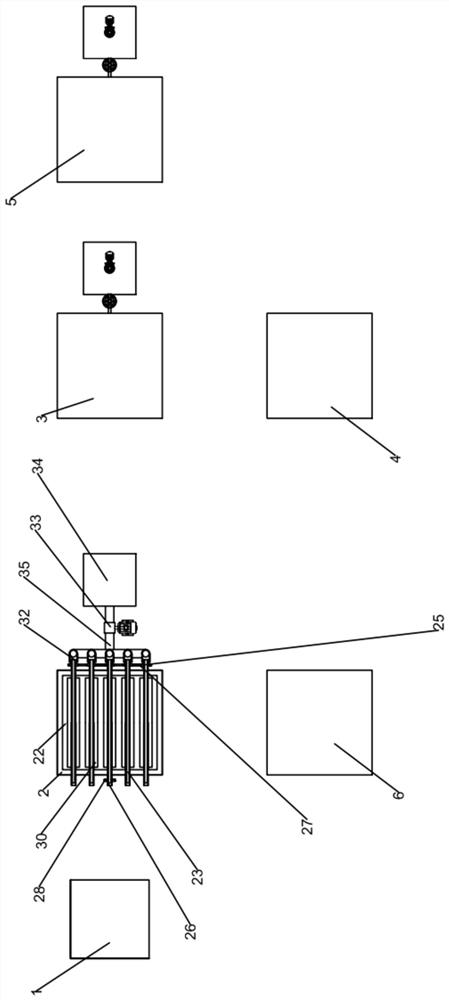

Method and device for carrying out integrated in-situ treatment on waste solvents

PendingCN107792996AImprove biodegradabilityReduce flammable and explosive safety hazardsWater treatment compoundsSpecific water treatment objectivesMicroorganismTreatment pond

The invention belongs to the field of waste water treatment, and relates to a device for carrying out integrated in-situ treatment on waste solvents. The device comprises an adjusting tank, a first stage coagulative precipitation tank, a first stage aeration micro-electrolytic cell, a first stage Fenton oxidation tank, a second stage coagulative precipitation tank, a second stage aeration micro-electrolytic cell, a second stage Fenton oxidation tank, a third stage coagulative precipitation tank and a biochemical treatment pond. The invention also discloses a method for carrying out integratedin-situ treatment on the waste solvents. The method and the device for carrying out integrated in-situ treatment on the waste solvents solve the problem that the existing non-polar waste solvent recovery and treatment method is high in cost and has safety hazards of being inflammable and explosive. After the device and the method are adopted, the concentration of CODCr in the waste solvents can beeffectively reduced, the toxicity of organic matters to microorganisms is reduced, the biodegradability of the waste solvents is improved, and the waste solvents are enabled to reach the discharge standard of sewage after being subjected to the ordinary biochemical treatment.

Owner:深圳瑞赛环保科技有限公司

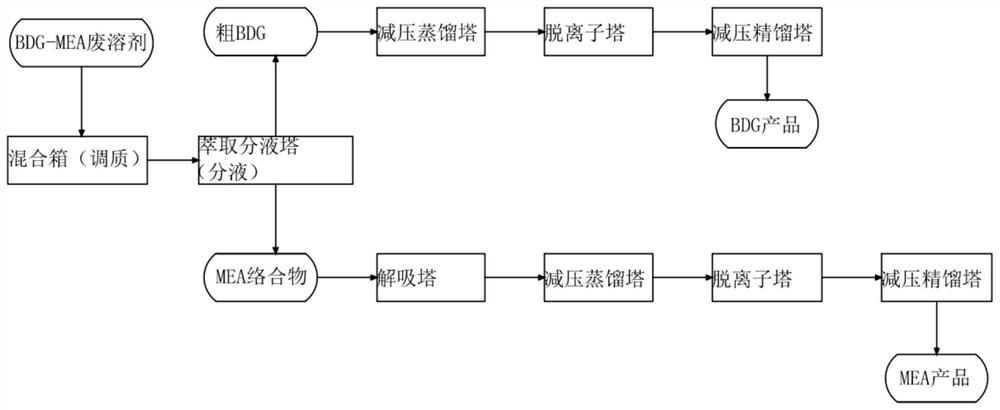

Method and equipment for purifying ethanolamine and diethylene glycol monobutyl ether in electronic waste solution

InactiveCN113429304AEnable recyclingReduce pollutionEther separation/purificationOrganic compound preparationDiethylene glycol monobutyl etherPhotovoltaic industry

The invention discloses a method and equipment for purifying ethanolamine and diethylene glycol monobutyl ether in an electronic waste solution, and the method and equipment have the beneficial effects that impurities in waste diethylene glycol monobutyl ether and ethanolamine stripping liquid are removed by liquid separation, gas stripping method separation, decompressed distillation deionization tower deionization and decompressed distillation; the electronic-grade organic solvent diethylene glycol monobutyl ether and the electronic-grade organic solvent ethanolamine are obtained. According to the purification method for the high-purity organic solvents diethylene glycol monobutyl ether and ethanolamine, through a series of low-energy-consumption procedures of liquid separation, gas stripping desorption, reduced pressure distillation, desorption tower desorption and reduced pressure rectification, the pollution degree of waste solvents to the environment in photovoltaic industry production is reduced, and the production cost is saved.

Owner:四川熔增环保科技有限公司

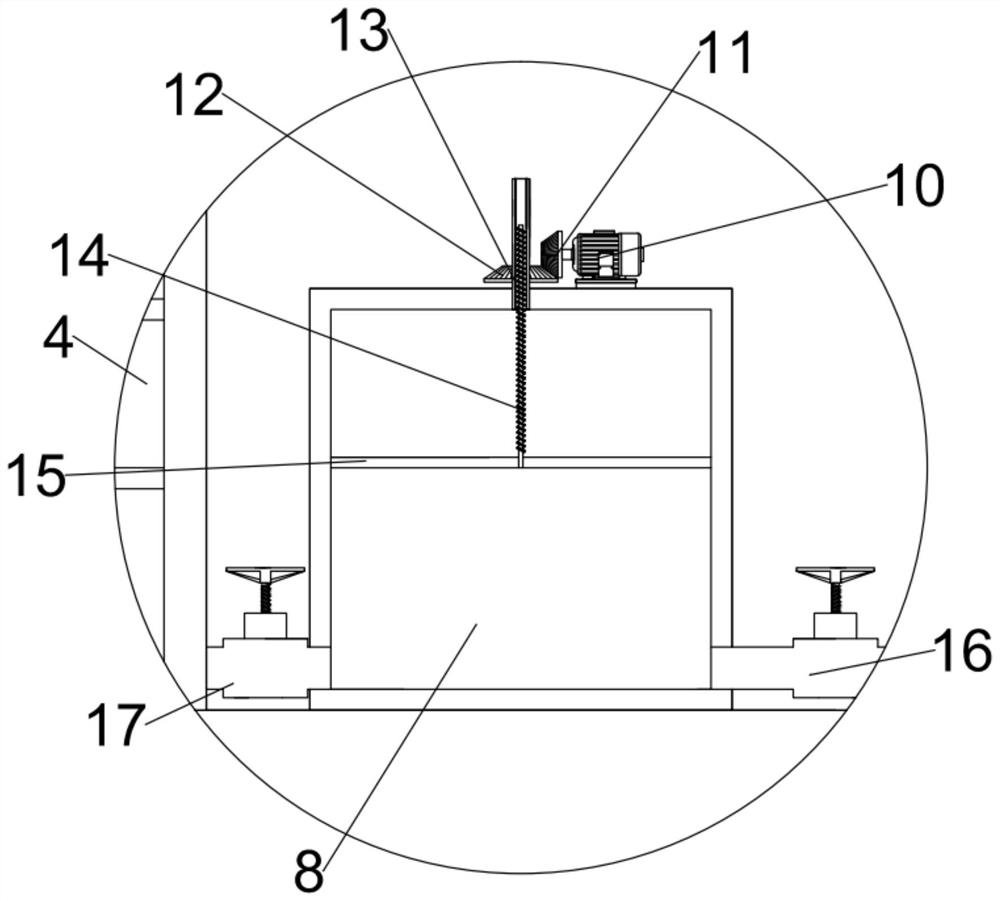

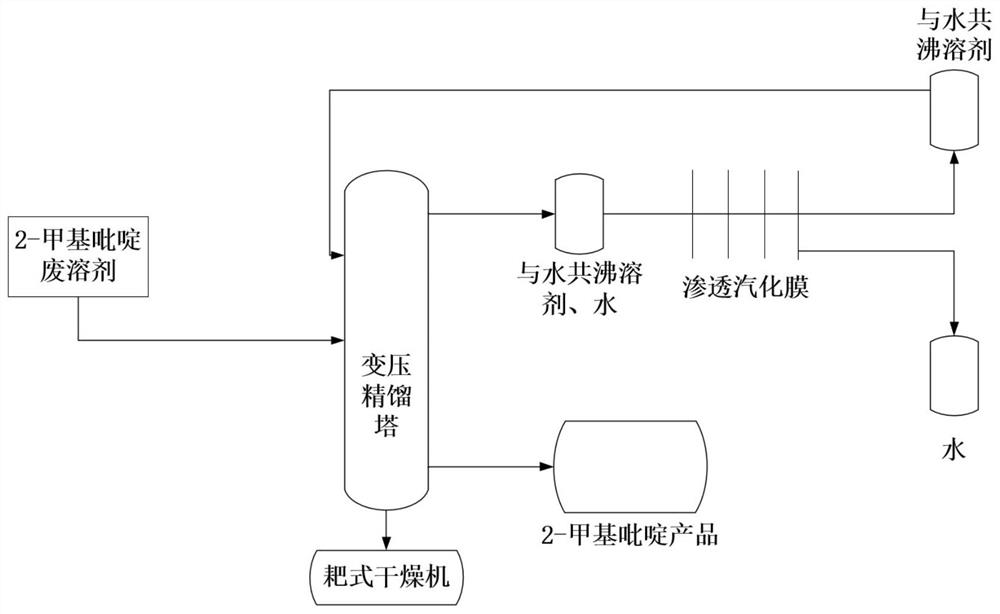

Method for recovering and purifying 2-methylpyridine waste liquid

InactiveCN113527184AEasy to purifyReduce pollutionOrganic chemistryDrying chambers/containersDistillationMethyl palmoxirate

The invention discloses a method for recovering and purifying 2-methylpyridine waste liquid. The method comprises the following steps that: a, agrochemical waste containing sulfonate, sodium chloride and 2-methylpyridine is weighed, then is introduced into a pressure-swing rectifying tower at a certain flow rate, and is rectified at a certain temperature and pressure; b, a rectified tower top component is an organic component azeotropic with water, the component enters a pervaporation membrane in the form of steam under certain flow and pressure control and undergoes dehydration, a dehydrated organic solvent is introduced into the pressure-swing rectifying tower at a certain flow, and water in the pressure-swing rectifying tower is circularly removed; and c, a 2-methylpyridine finished product is extracted at a certain flow rate from the side line position of the pressure-swing rectifying tower. The industrial-grade 2-methylpyridine is obtained through the methods of pressure swing distillation, pervaporation membrane-coupled distillation dehydration, azeotropic solvent recycling, side-drawing of the product and drying of a tower-bottom material through a rake type drying mechanism, and the industrial-grade 2-methylpyridine can be easily purified from a agrochemical waste solvent containing sulfonate and sodium chloride.

Owner:四川熔增环保科技有限公司

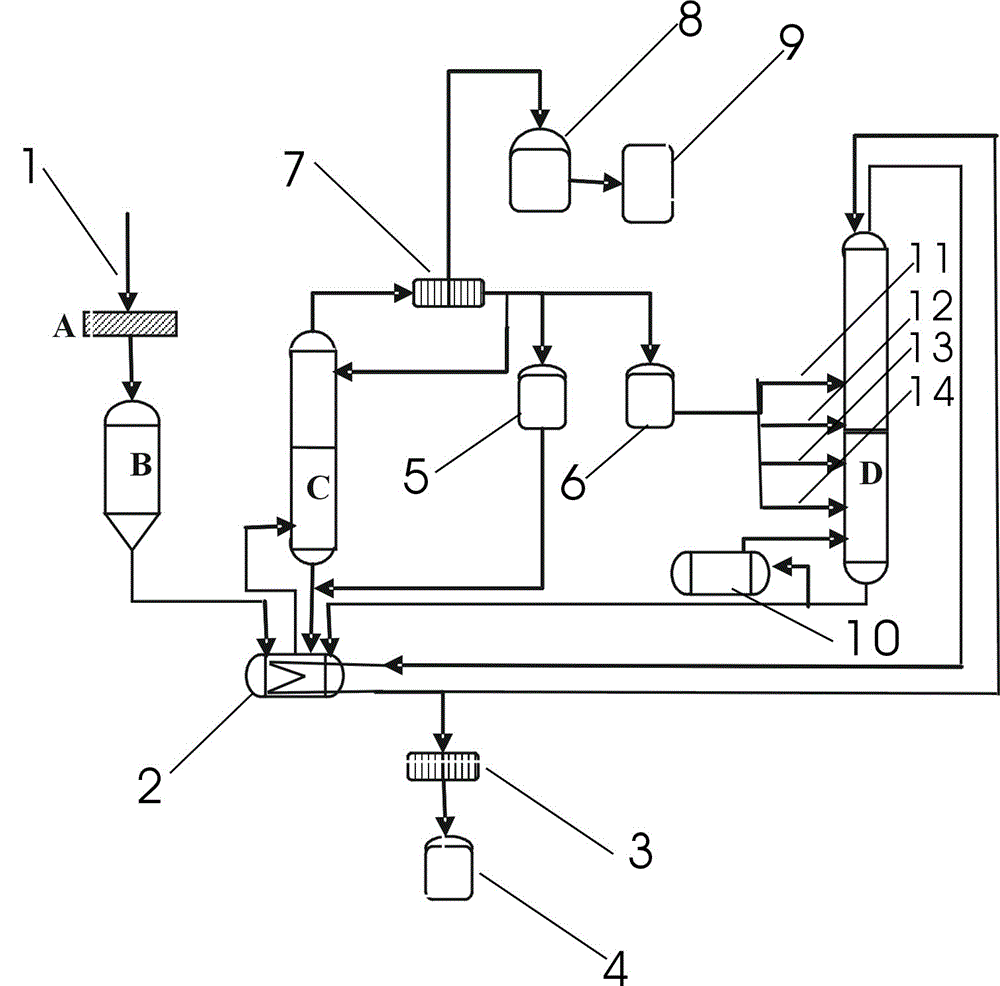

Extraction-rectification recovery method of N-methyl pyrrolidone in waste solvent

The invention provides an extraction-rectification recovery method of N-methyl pyrrolidone. The N-methyl pyrrolidone is recycled by taking a selected solvent or a composite solvent as an extracting agent and an extraction-rectification technology as a core, and the method specifically comprises the following steps: firstly, extracting by using the extracting agent, rectifying an obtained extractedphase to respectively recycle the N-methyl pyrrolidone and the extracting agent, and refining the N-methyl pyrrolidone to finally obtain a product. According to the method, the extraction efficiencyof the selected extracting agent is high, the process technology is green, simple and convenient, the operability is high, the purity of the obtained N-methyl pyrrolidone is larger than 99.7%, the moisture content is lower than 200 ppm, the recovery rate is 97% or above, compared with other technological methods, the process energy consumption is remarkably reduced, and industrial production is facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

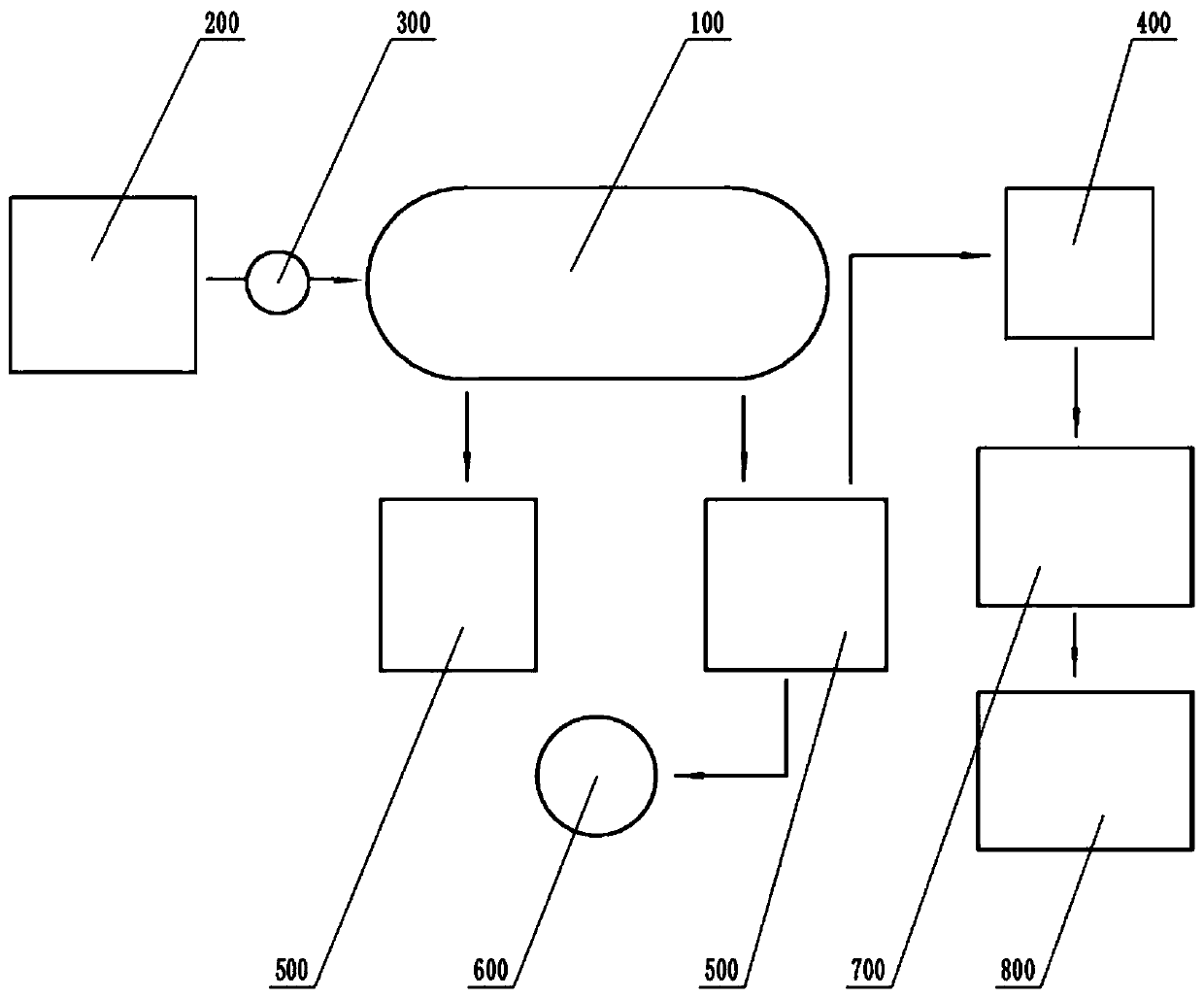

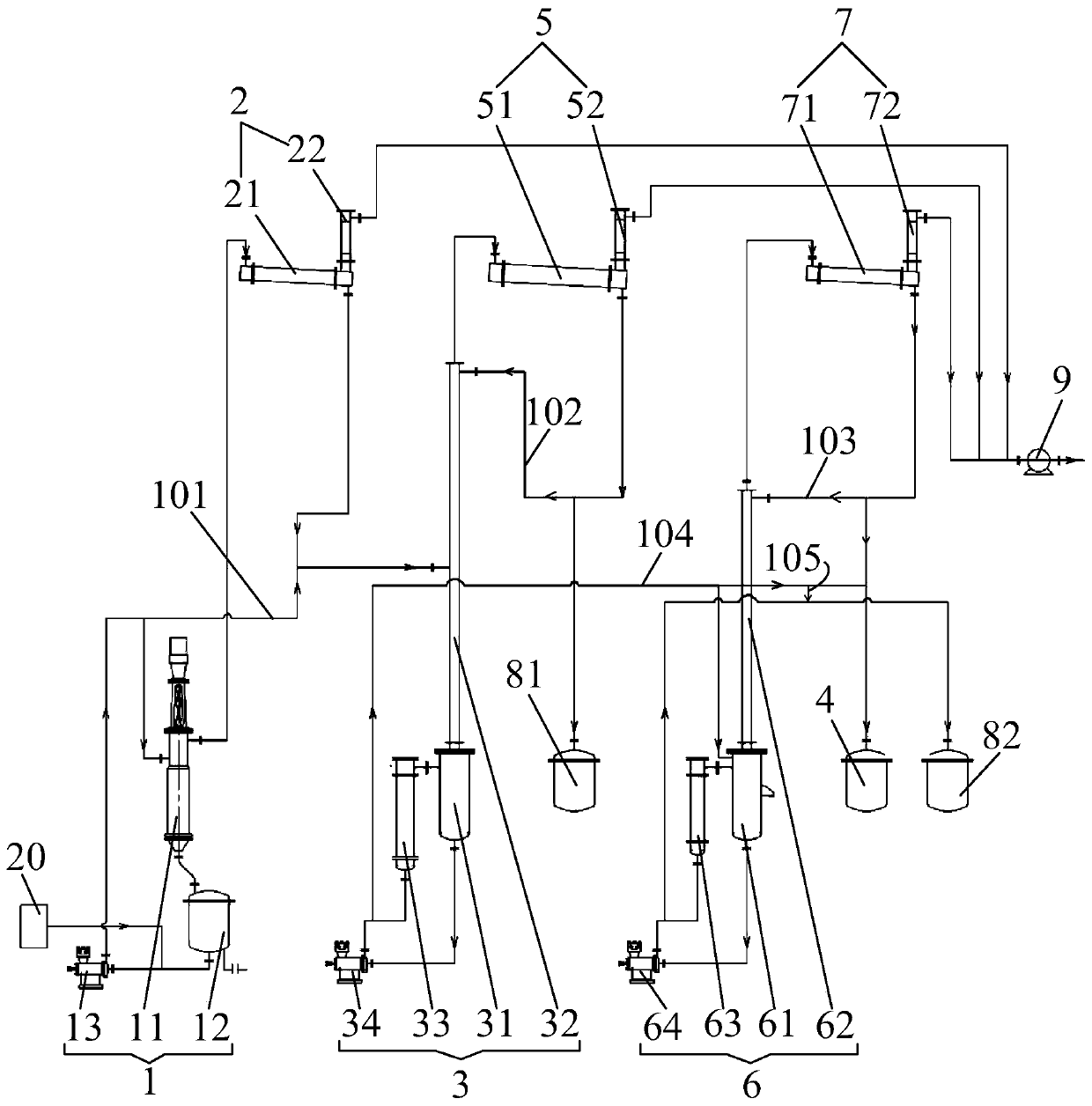

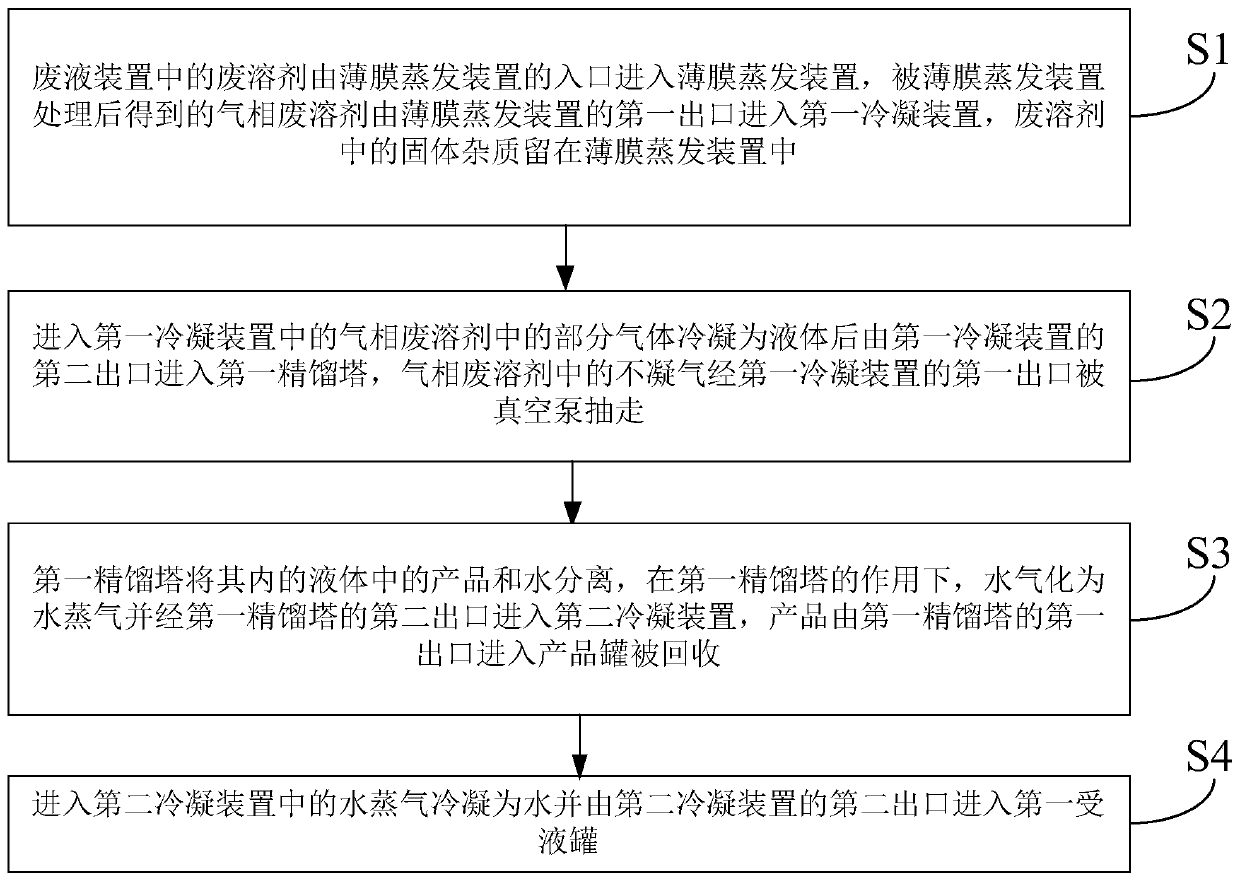

Waste solvent recovery system and method

PendingCN111228837AImprove efficiencyReduce contentDistillation regulation/controlMultiple-effect/fractional condensationThermodynamicsProcess engineering

The invention discloses a waste solvent recovery system and method, and belongs to the technical field of waste solvent recycling. The waste solvent recovery system comprises a film evaporation device, a first condensation device, a first rectification tower, a product tank and a second condensation device. The film evaporation device is communicated with a waste liquid device containing a waste solvent, and the first condensation device is respectively communicated with the film evaporation device and the vacuum pump; the first rectifying tower is communicated with the first condensing device, and the first rectifying tower is used for removing part of impurities in the condensed waste solvent; the product tank is communicated with the first rectifying tower and is used for containing thewaste solvent from the first rectifying tower; the second condensing device is respectively communicated with the first rectifying tower, the vacuum pump and the first liquid receiving tank, is communicated with the first liquid receiving tank and is used for condensing low-boiling-point impurities. The product treated by the waste solvent recovery system provided by the invention is relatively high in purity and relatively low in impurity content.

Owner:SHANGHAI MORIMATSU PHARMA EQUIP ENG

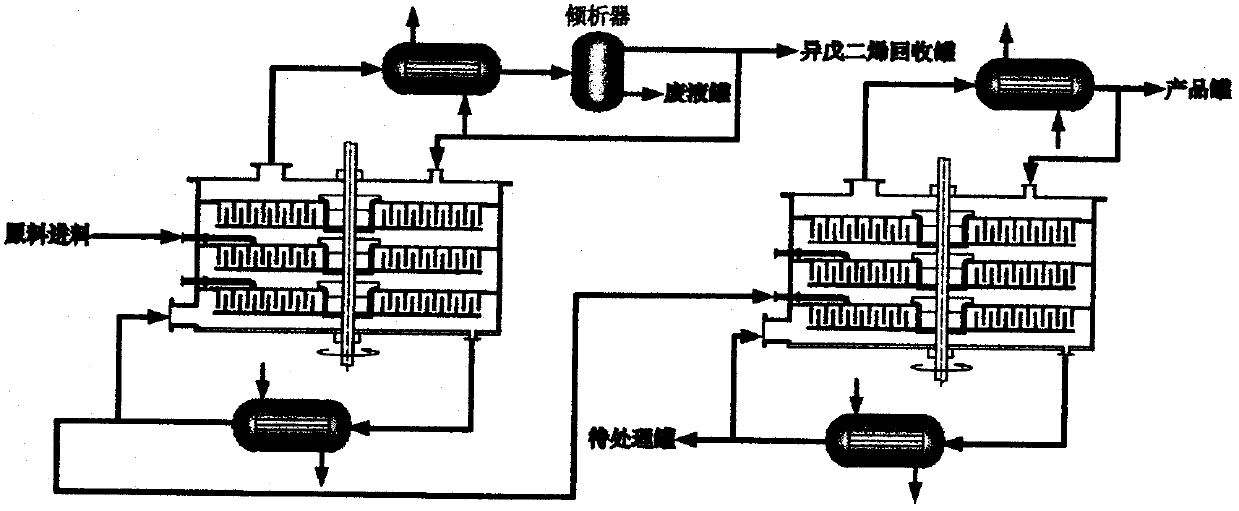

Process for recycling methyl tertbutyl ether-tetrahydrofuran from waste solvent obtained in statins medicine synthetic process by using high-gravity beds

InactiveCN107586256AHigh purityEther separation/purificationOrganic compound preparationEconomic benefitsEther

The invention relates to a methyl tertbutyl ether-tetrahydrofuran rectification process, which takes rectification as a core method and aims at recycling an organic waste solvent in a statins medicinesynthetic process, wherein the methyl tertbutyl ether-tetrahydrofuran meets application requirement. According to the process, a waste solvent enters the space between the rotors in the second and third layers of a first high-gravity bed, the temperature of a tower top is controlled at 34-36 DEG C, the tower top product is layered with a decanter, and an isoprene coarse product is obtained from the top layer. A tower bottom material enters the space between the rotors in the first and second layers of a second high-gravity bed, the operation temperature of the tower top is controlled at 55-58DEG C, and a methyl tertbutyl ether-tetrahydrofuran mixed solvent with the purity more than 97% and the water content less than 1000 ppm is obtained from the tower top. According to the process, a recycling process using two in-series high-gravity beds is adopted. The process is simple in route, small in equipment space occupation, and low in energy consumption. The recycling utilization rate ofa regenerative solvent is improved, and the economic benefit of an enterprise is increased.

Owner:南京揽博环境技术有限公司 +1

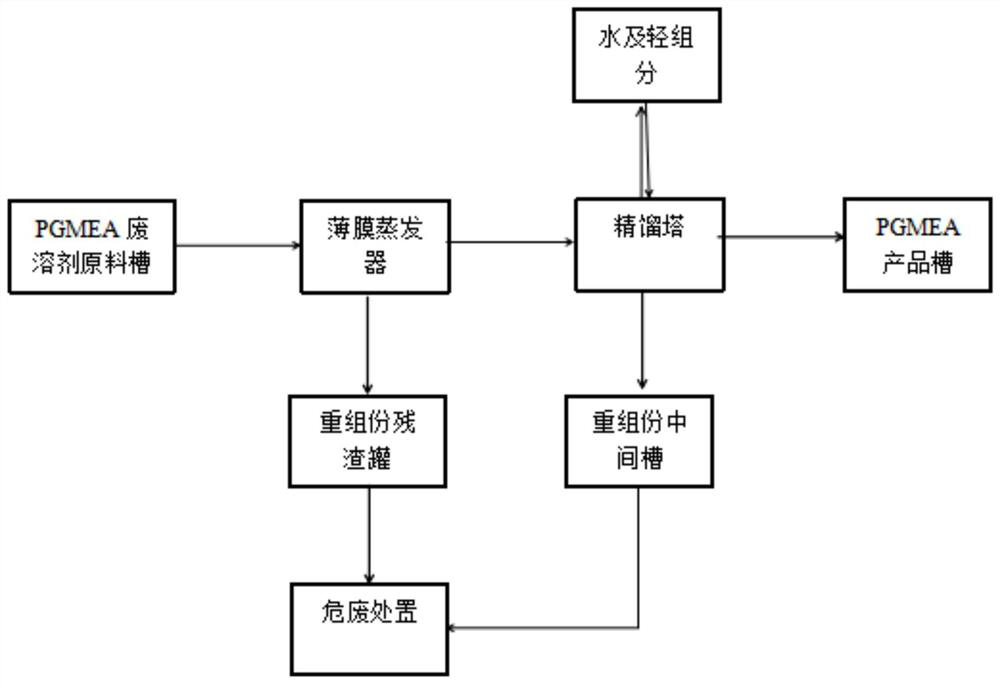

Method for recovering PGMEA from electronic PGMEA waste solvent

PendingCN113072447ALow impurity contentHigh purityOrganic compound preparationCarboxylic acid esters separation/purificationProcess engineeringPhotoresist

The invention belongs to the technical field of carboxylic ester extraction, and discloses a method for recovering PGMEA from an electronic PGMEA waste solvent. The method comprises the following steps: firstly, introducing the waste solvent into a film evaporator, heating by using steam to generate a waste solvent gas phase, introducing the waste solvent gas phase into a condenser, condensing to form a PGMEA semi-finished product, and introducing the PGMEA semi-finished product into a solvent receiving intermediate tank; introducing the PGMEA semi-finished product into a rectifying tower, and keeping the tower top pressure of the rectifying tower at 5-15 KPa, the tower top temperature of the rectifying tower at 48-52 DEG C, the tower kettle temperature of the rectifying tower at 85-89 DEG C, and the temperature of the side line of the rectifying tower at 82-86 DEG C; and finally, extracting PGMEA from the side line of the rectifying tower. According to the invention, the problem that the purity of the recovered PGMEA is low because the photoresist in the waste solvent cannot be removed in the prior art is solved.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

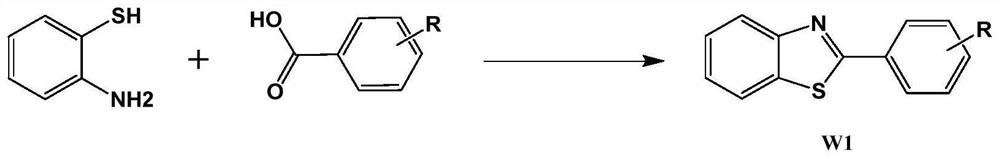

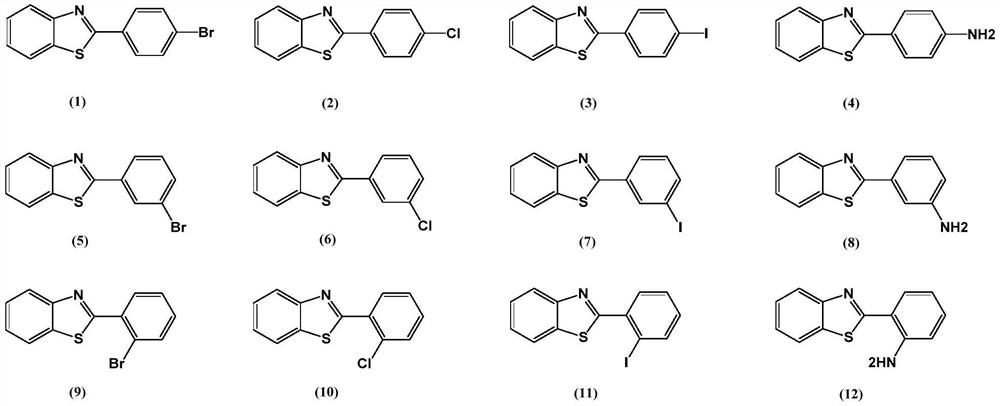

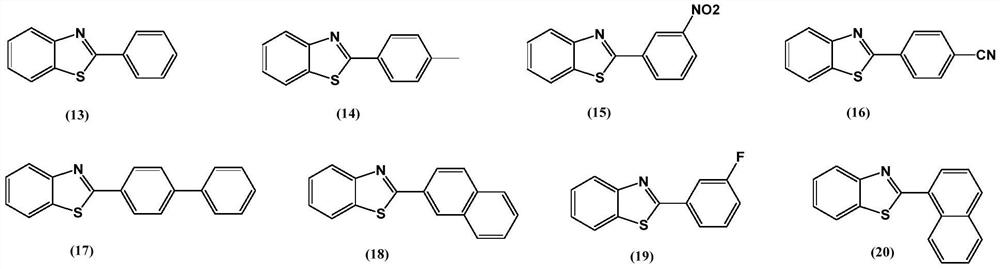

Preparation method of 2-phenylbenzothiazole derivative

The invention belongs to the technical field of organic chemical synthesis, and particularly relates to a preparation method of a 2-phenylbenzothiazole derivative. An existing 2-phenylbenzothiazole derivative is high in raw material pollution, high in price, long in reaction step, complex in reaction, low in yield and complex in post-treatment. The invention provides the preparation method of the 2-phenylbenzothiazole derivative. Substituted aryl carboxylic acid and o-aminothiophenol are used as raw materials to react to obtain the 2-phenylbenzothiazole derivative. No waste solvent is generated, less waste water is generated, and the atom utilization rate is high, so that the method is more environment-friendly.

Owner:陕西维世诺新材料有限公司

Method for recovering waste solvents of ethyl acetate, n-butyl alcohol and n-heptane

ActiveCN111875499AImprove solubilityReduce energy consumptionOrganic compound preparationDistillation purification/separationExtractive distillationEthyl acetate

The invention discloses a method for recovering a waste solvent of ethyl acetate, n-butyl alcohol and n-heptane, which comprises the following steps: (1) reducing the mass content of water in the solvent to obtain a mixture only containing ethyl acetate, n-butyl alcohol and n-heptane; (2) introducing the mixture of ethyl acetate, n-butyl alcohol and n-heptane into a first rectifying tower for azeotropic distillation to obtain n-butyl alcohol at the bottom of the tower and an azeotropic mixture of ethyl acetate and n-heptane at the top of the tower; (3) introducing the azeotropic mixture of ethyl acetate and n-heptane into a second rectifying tower, adding a mixed extractant composed of an extractant and an ionic liquid, and carrying out extractive distillation to obtain n-heptane at the tower top and a mixture of ethyl acetate and the mixed extractant at the tower bottom; and (4) continuously introducing the mixture of ethyl acetate and the extraction agent into a solvent recovery tower to obtain ethyl acetate at the top of the tower and a mixed extraction agent at the bottom of the tower. According to the method, ethyl acetate, n-butyl alcohol and n-heptane can be efficiently separated.

Owner:ANQING XINXIANGRUI CHEM CO LTD

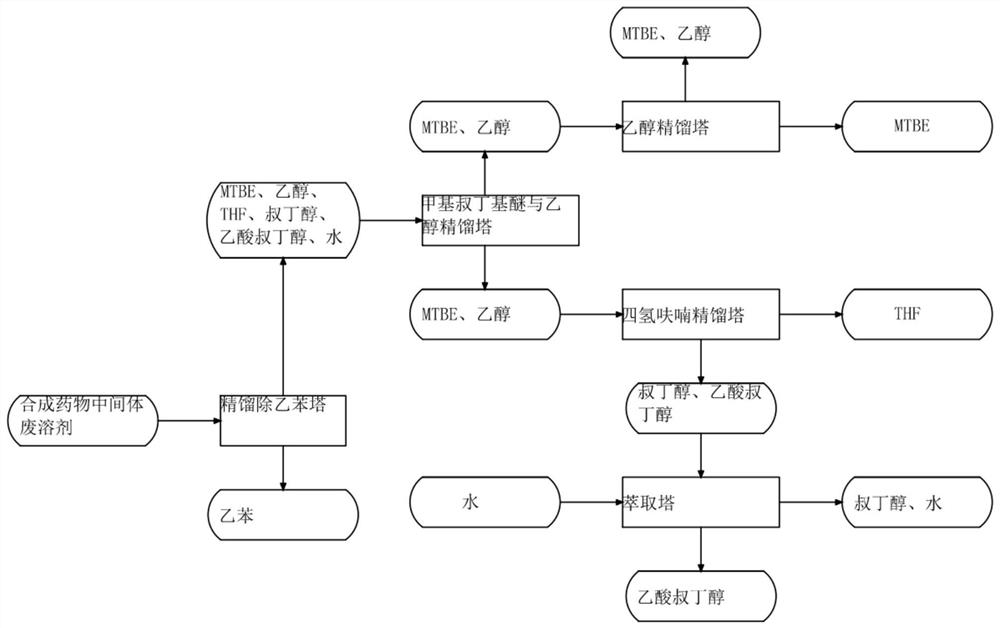

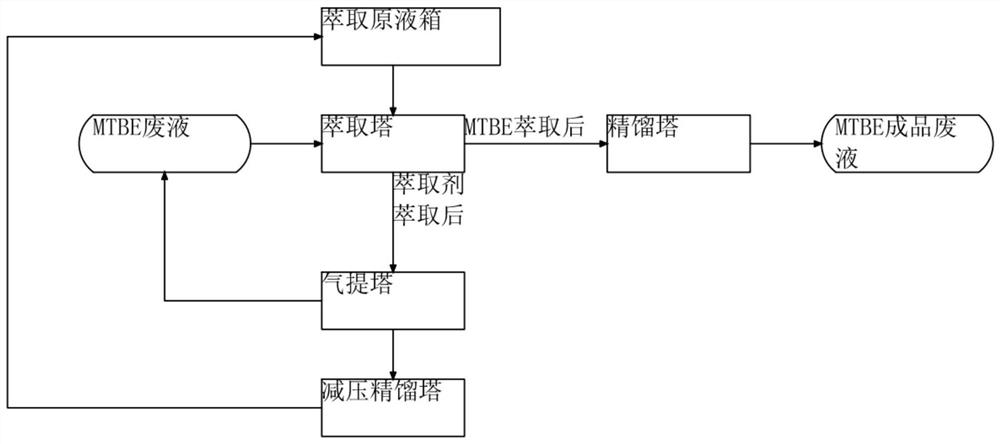

Method and equipment for recovering and purifying MTBE (methyl tert-butyl ether) waste solvent generated by synthesizing drug intermediate

InactiveCN113527071AReduce pollutionAchieve reuseEther separation/purificationOrganic solventPharmaceutical industry

The invention discloses a method and equipment for recovering and purifying MTBE (Methyl Tert-Butyl Ether) waste solvent generated by synthesizing a drug intermediate. The method and the equipment have the beneficial effects that impurities in the waste solvent for synthesizing the drug intermediate are removed through a series of methods such as rectification, liquid-liquid extraction and the like, and an organic solvent still having recycling value is recovered. According to the recovery and purification method provided by the invention, the waste solvent for synthesizing the drug intermediate is separated through a series of low-energy-consumption processes of rectification and extraction, so that the solvent with recycling value is recycled, the pollution degree of the waste solvent to the environment in the pharmaceutical industry is reduced, and the production cost is reduced.

Owner:四川熔增环保科技有限公司

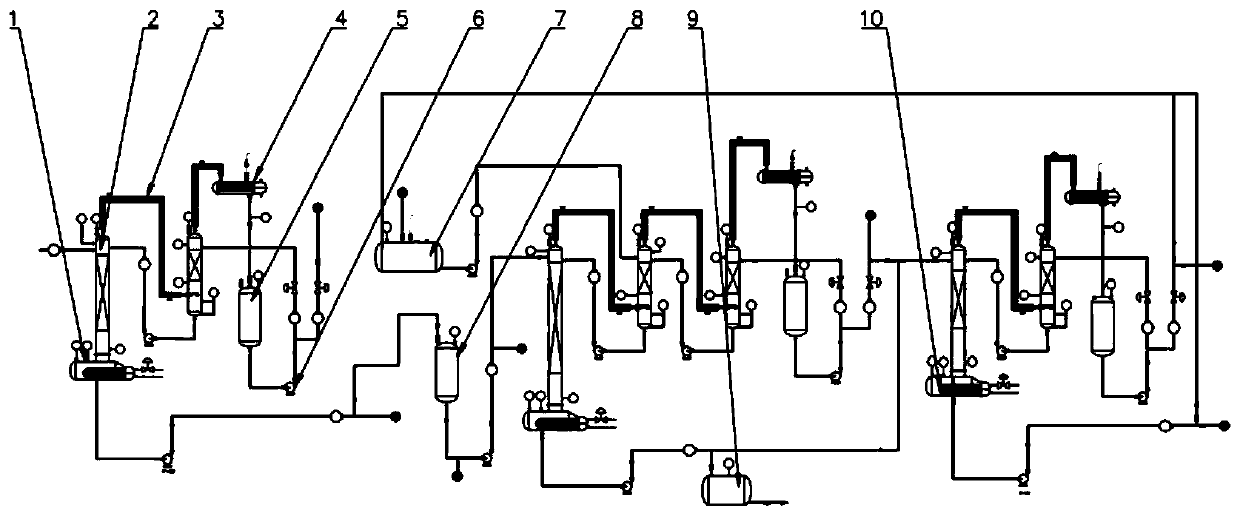

Multifunctional solvent rectification recovery device

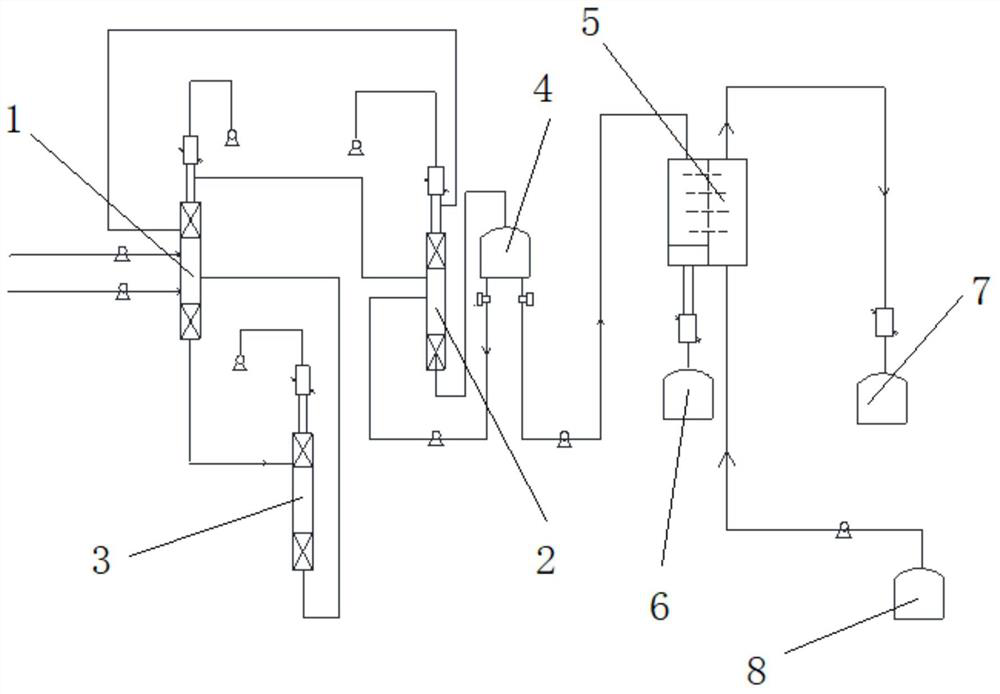

A multifunctional solvent rectification recovery device comprises multiple stages of solvent rectification recovery mechanisms. Each stage of solvent rectification recovery mechanism comprises a rectifying tower, a reboiler, a condenser and a reflux tank, wherein the inlet end of the rectifying tower is communicated with an input pipeline, the inlet end of the reboiler is communicated with the liquid phase outlet end of the rectifying tower, the liquid phase outlet end of the reboiler is communicated with an output pipeline, the gas phase outlet end of the reboiler is communicated with the inlet end of the rectifying tower, the gas phase outlet end of the rectifying tower is communicated with the inlet end of the condenser, the outlet end of the condenser is communicated with the reflux tank, the reflux tank is communicated with a discharge pipeline, and the discharge pipeline is further connected with a reflux pipeline communicated with the rectifying tower. The input pipeline of thelater-stage solvent rectification recovery mechanism is communicated with the output pipeline of the previous-stage solvent rectification recovery mechanism. The device is reasonable in design and high in automation degree, waste can be turned into wealth, waste solvents generated by medical and chemical enterprises can be rectified, recycled and reused, and coordination and unification of society, economy and environmental governance are achieved.

Owner:江苏京控装备有限公司

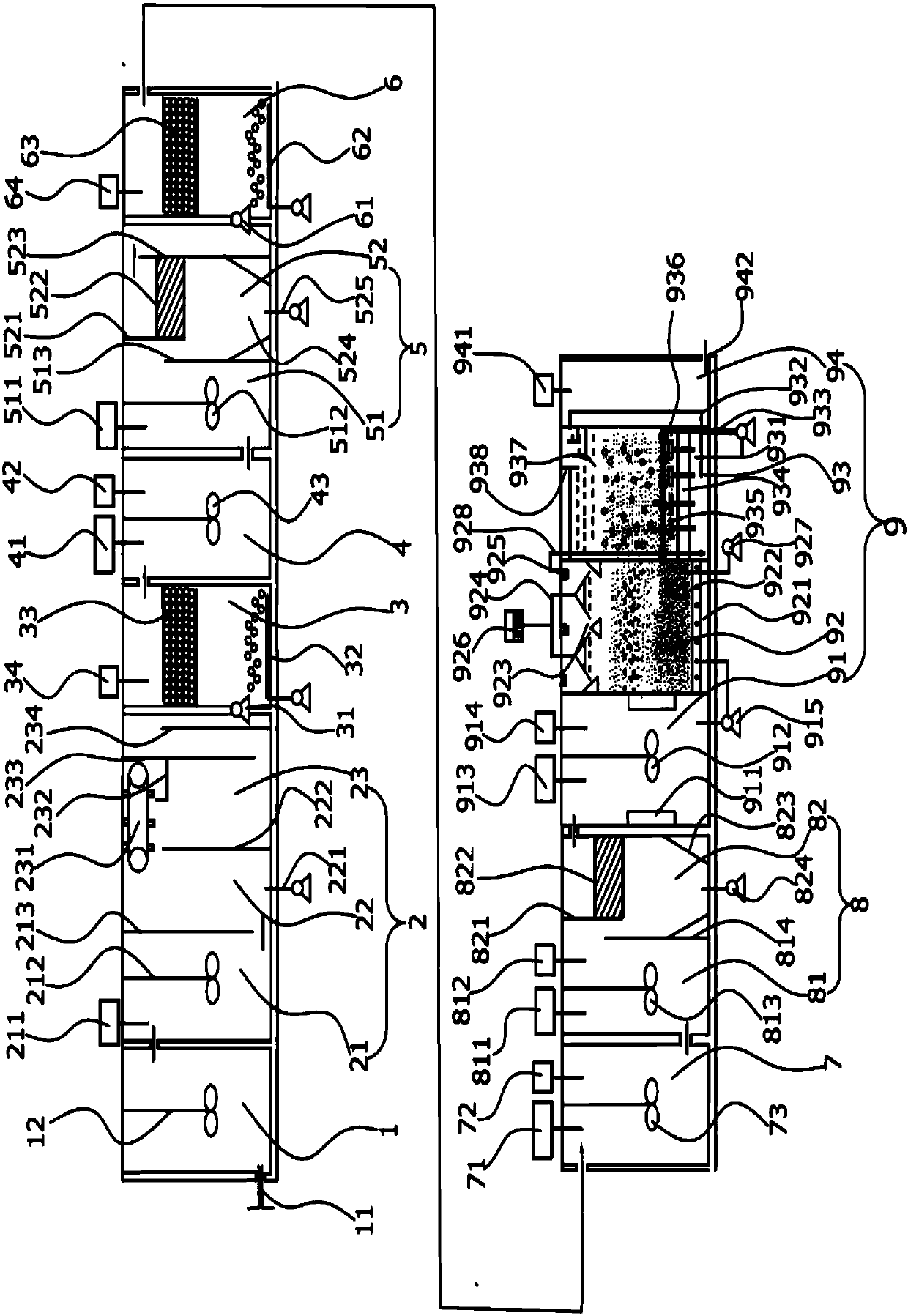

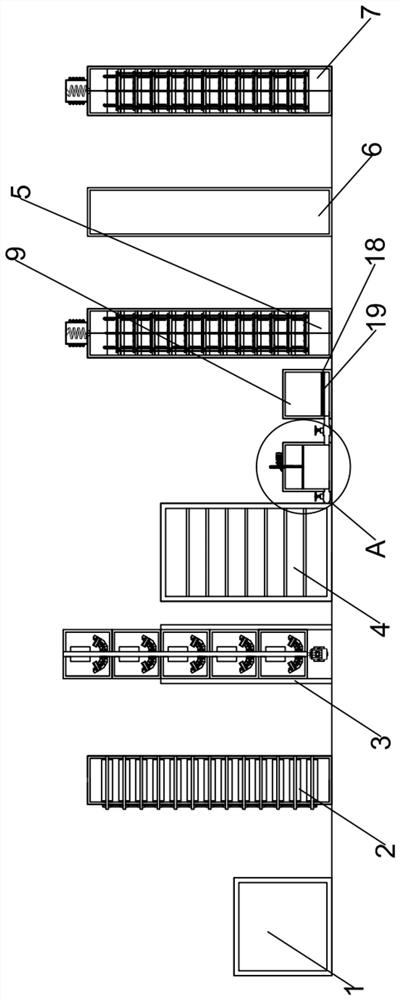

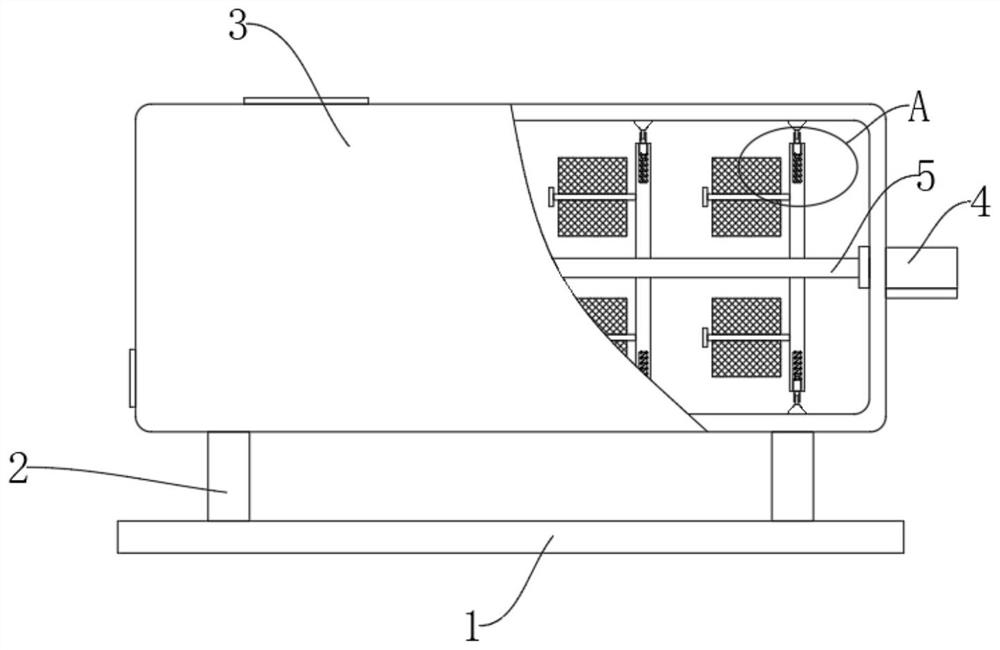

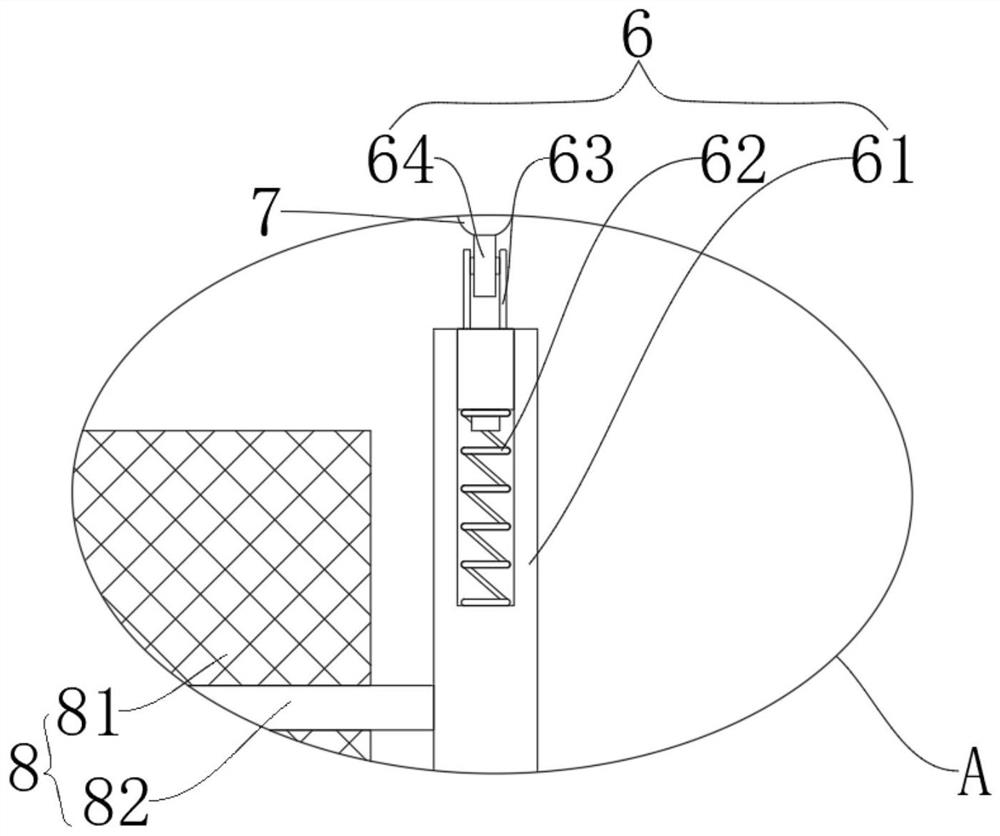

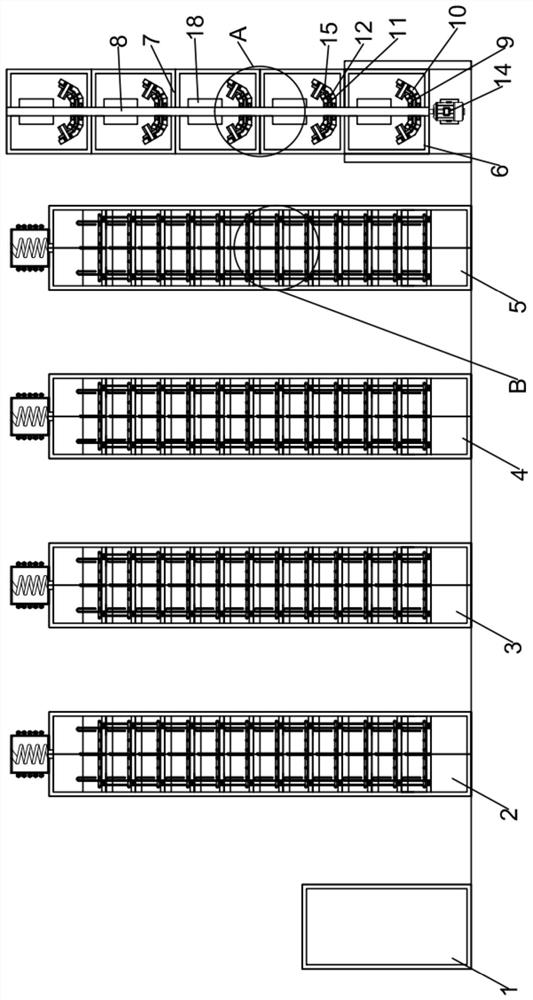

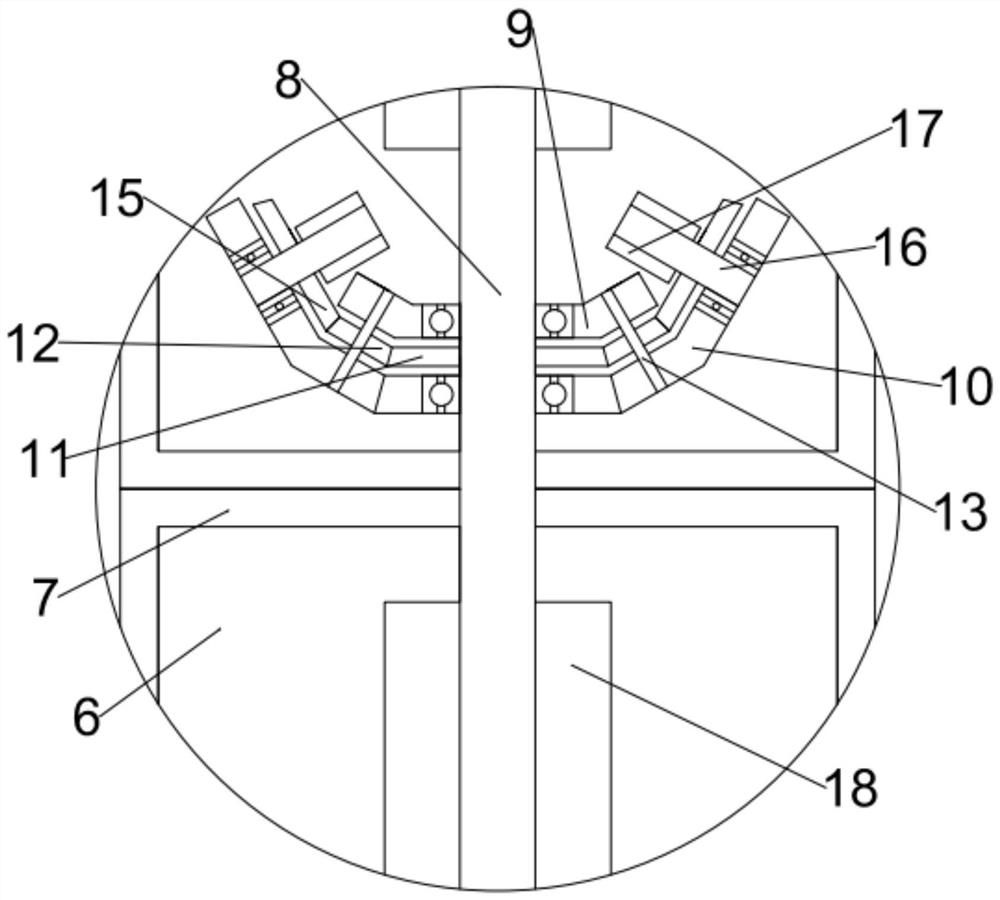

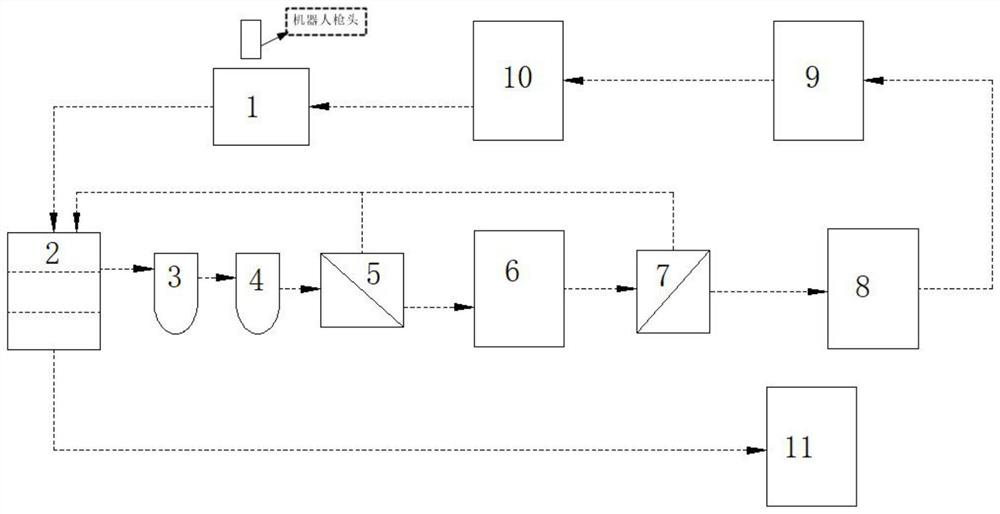

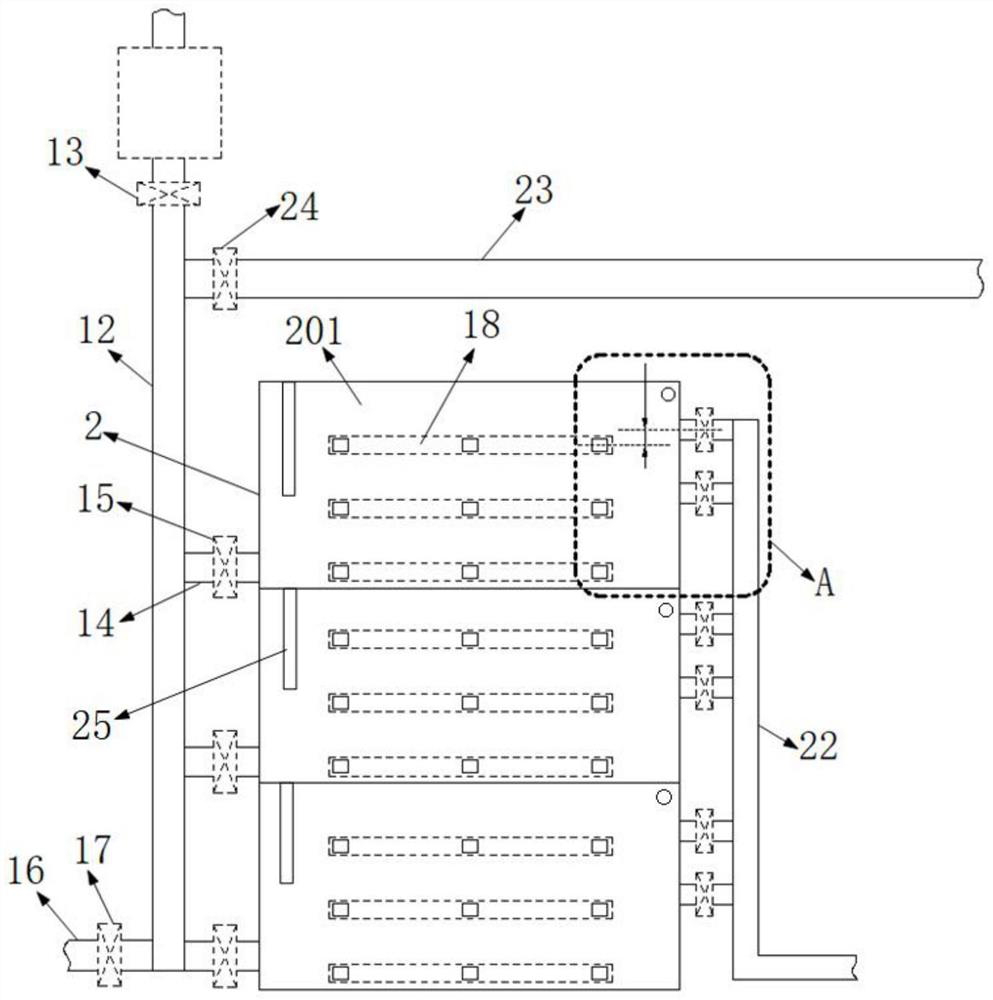

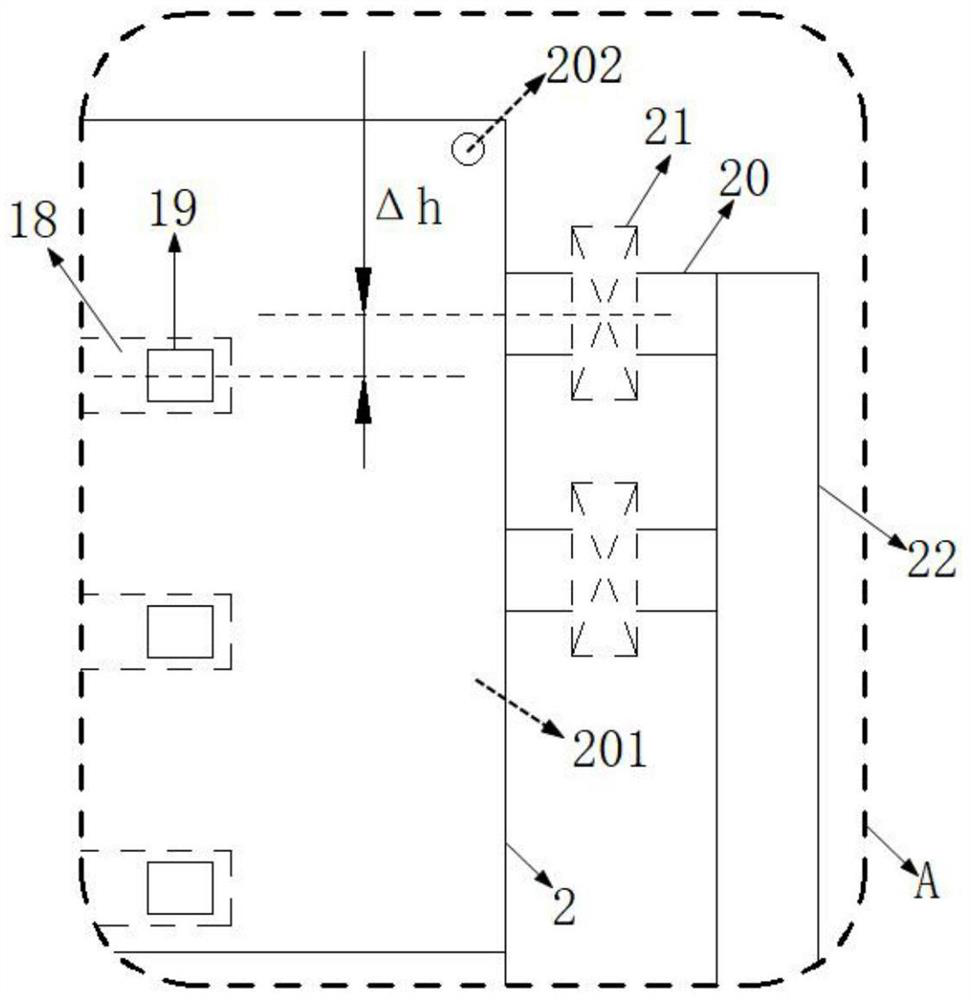

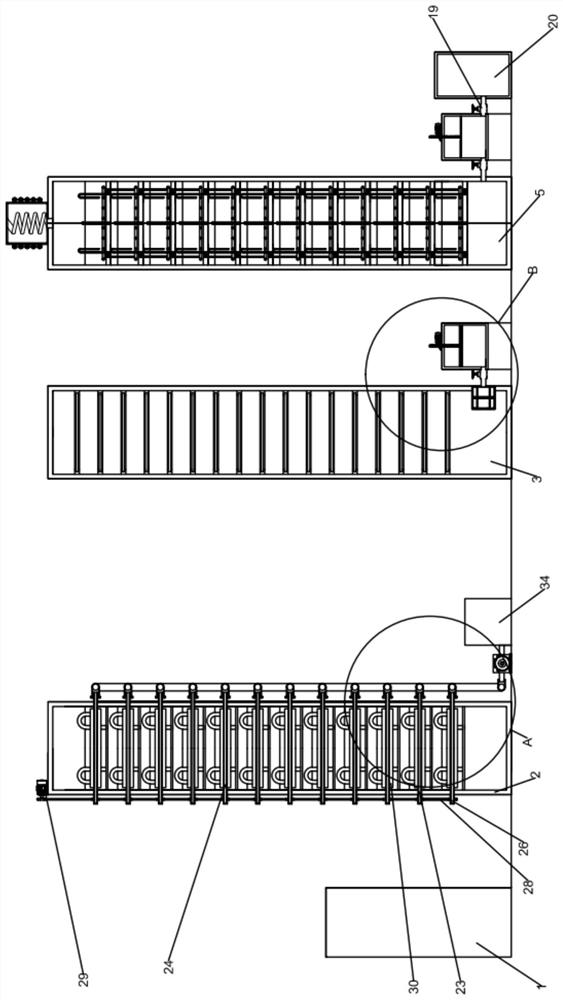

Dynamic separation and recovery device for water-based paint cleaning solvent and driving control method

PendingCN114477504AHigh recovery rateHigh economic valueTreatment involving filtrationMultistage water/sewage treatmentProcess engineeringEnvironmental engineering

The invention discloses a dynamic separation and recovery device for a water-based paint cleaning solvent and a driving control method, and relates to the technical field of water-based paint cleaning solvent recovery. A cleaning solvent is collected through a cleaning closestool and enters a stock solution tank for standing and settling, supernatant liquid is filtered through a primary 50-micron filter bag, a 5-micron filter element and a UF membrane, then liquid is guided into a first-stage clear liquid tank, liquid in the first-stage clear liquid tank is filtered through an RO membrane, clear liquid enters a recovery solution tank, concentrated liquid filtered out through the UF membrane and the RO membrane flows back to the stock solution tank, and the concentrated liquid enters a second-stage clear liquid tank. The concentrated liquid which is left to stand and settled in the stock solution tank is guided into the paint mixing room concentrated liquid collecting tank, the clear liquid in the recovery solution tank is guided into the secondary proportioning tank, the solvent is supplemented in the secondary proportioning tank, the liquid in the secondary proportioning tank is guided into the paint mixing room solvent tank after the solvent is supplemented, and the cleaning solvent is supplied to the spray gun head of the robot. The recycling rate of the water-based paint waste solvent is increased, and the recycling time-consuming efficiency of the water-based paint waste solvent in the recycling process is improved.

Owner:北京海得科过滤技术有限公司

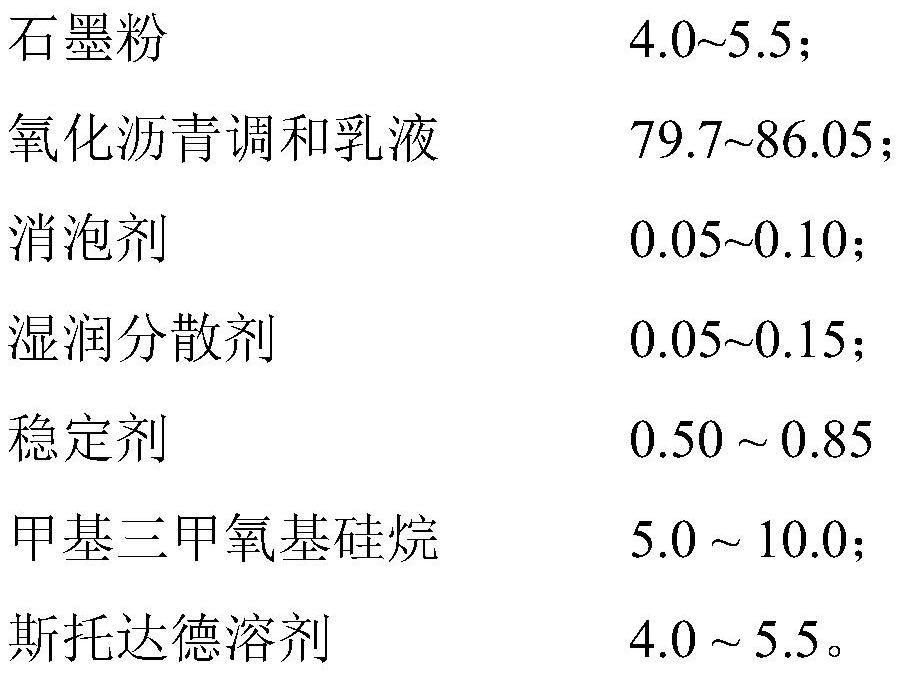

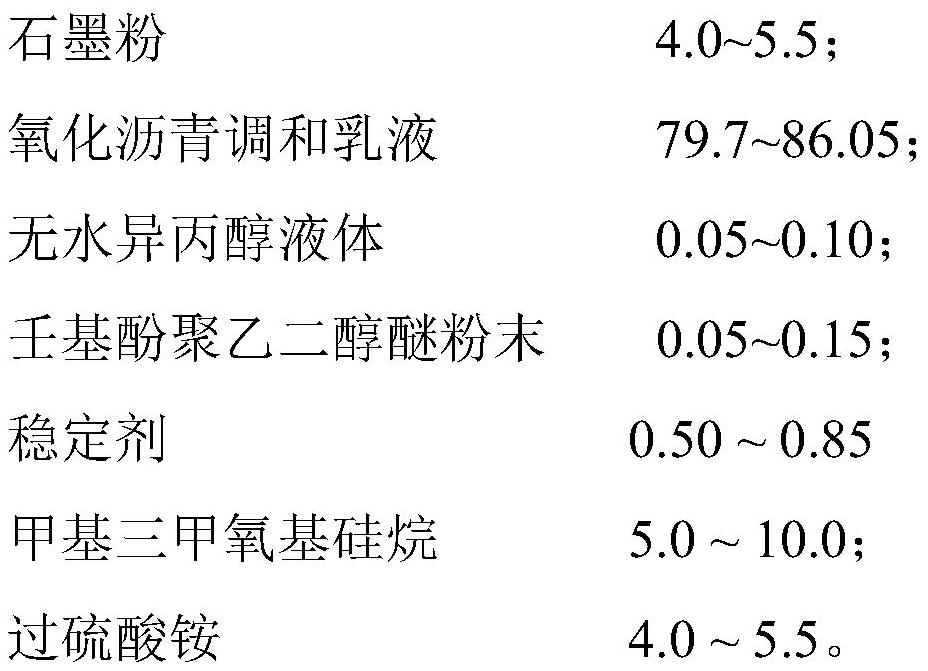

A kind of asphalt concrete pavement protective agent and its preparation method and application

The invention relates to an asphalt concrete pavement protective agent and its preparation method and application. The protective agent comprises the following components in weight percent: graphite powder 4.0-5.5; oxidized asphalt blend emulsion 79.7-86.05; defoamer 0.05-0.10; Wetting and dispersing agent 0.05~0.15; Stabilizer 0.50~0.85 Methyltrimethoxysilane 5.0~10.0; Stoddard solvent 4.0~5.5, added when newly pouring asphalt concrete to achieve curing function. Compared with the prior art, the present invention has the advantages of simple production process, low cost, outstanding protective effect, non-toxic and non-polluting, realizes the function of curing agent in the initial stage of asphalt concrete pouring, and exerts its protective agent function during the use of the road surface, greatly It greatly improves the ability of asphalt concrete to resist the erosion of various media and prolongs the service life of asphalt concrete, which is an environmentally friendly building material.

Owner:HEBEI CONSTR GRP CO LTD

Method and equipment for recovering and purifying methyl tert-butyl ether waste solvent

The invention discloses a method and equipment for recovering and purifying a methyl tert-butyl ether waste solvent, which have the beneficial effects that a series of low-energy-consumption procedures for removing impurities in waste methyl tert-butyl ether are carried out through the methods of extraction separation, rectification gas stripping and vacuum rectification recovery; the waste methyl tert-butyl ether with the purity of only 80%-95% (wt) is purified into the industrial-grade organic solvent methyl tert-butyl ether with the purity of more than or equal to 99.9% (wt), so that the waste methyl tert-butyl ether is recycled, the pollution degree of the waste solvent generated in polypeptide production to the environment is reduced, and the production cost is reduced. The purification method provided by the invention also has the advantages of high yield, low energy consumption, good quality, recyclability, simple and convenient production process, stable operation, suitability for industrial production and the like.

Owner:四川熔增环保科技有限公司

Preparation method of substituted benzo [B] naphthyl benzene [2, 3-D] thiophene derivative and derivative

PendingCN114591290AEasy to operateSave raw materialsOrganic chemistryLuminescent compositionsThiophene derivativesMethyl palmoxirate

The invention discloses a preparation method of a substituted benzo [B] naphthobenzene [2, 3-D] thiophene derivative, which comprises the following steps: reacting 2-naphthyl dimethyl sulfide serving as a raw material at low temperature to obtain an intermediate S-1, carrying out coupling reaction on the intermediate S-1 and substituted o-iodobenzene to obtain an intermediate S-2, and carrying out demethylation reaction on the intermediate S-2 under the action of Lewis acid to obtain S-3, 5-disubstituted benzo [B] naphthobenzene [2, 3-D] thiophene derivative. The S-3 is subjected to a ring closing reaction under the action of alkali, and the product W0: substituted benzo [B] naphthyl benzene [2, 3-D] thiophene derivative is obtained. By adopting the preparation method of the substituted benzo [B] naphthobenzene [2, 3-D] thiophene derivative provided by the invention, the obtained product is high in purity, high in yield and low in cost, no waste solvent is generated in the whole preparation process, and meanwhile, less waste water is generated, so that a foundation is laid for realizing the aim of environmental protection.

Owner:陕西维世诺新材料有限公司

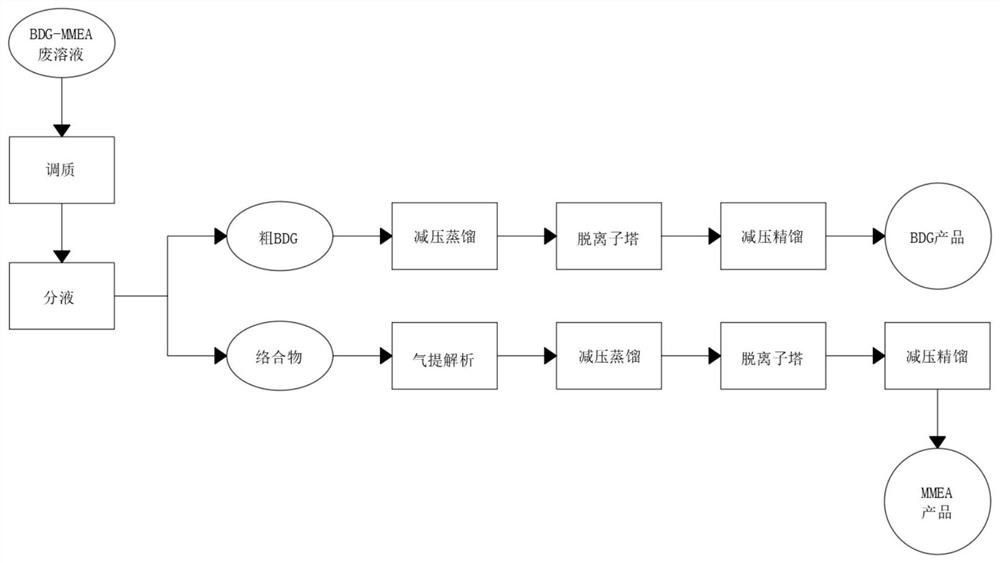

Method for recycling and purifying a mixed waste liquid of methylethanolamine and diethylene glycol monobutyl ether in the electronic industry

InactiveCN113429305AReduce pollutionEnable recyclingEther separation/purificationOrganic compound preparationDiethylene glycol monobutyl etherPhotovoltaic industry

The invention discloses a method for recycling and purifying a mixed waste liquid of methylethanolamine and diethylene glycol monobutyl ether in the electronic industry. Impurities in a waste solvent diethylene glycol monobutyl ether are removed through the methods of tempering, liquid separation, de-ionization tower de-ionization and vacuum rectification; impurities in the waste solvent methylethanolamine stripping liquid are removed through the methods of tempering, liquid separation, gas stripping desorption separation, de-ionization tower de-ionization and vacuum rectification; a waste material containing a plurality of impurities such as polymer resin, a photosensitizer and the like is purified through a series of low-energy-consumption processes such as liquid separation, gas stripping desorption separation, de-ionization tower de-ionization and vacuum rectification to obtain an electronic-grade organic solvent diethylene glycol monobutyl ether with the purity of more than or equal to 99.7% (wt) and an industrial-grade organic solvent methylethanolamine with the purity of more than or equal to 99.0% (wt); the recycling of the waste materials diethylene glycol monobutyl ether and methylethanolamine is realized, the pollution degree of the waste solvent to the environment in the production of the photovoltaic industry is reduced, and the production cost is saved.

Owner:四川熔增环保科技有限公司

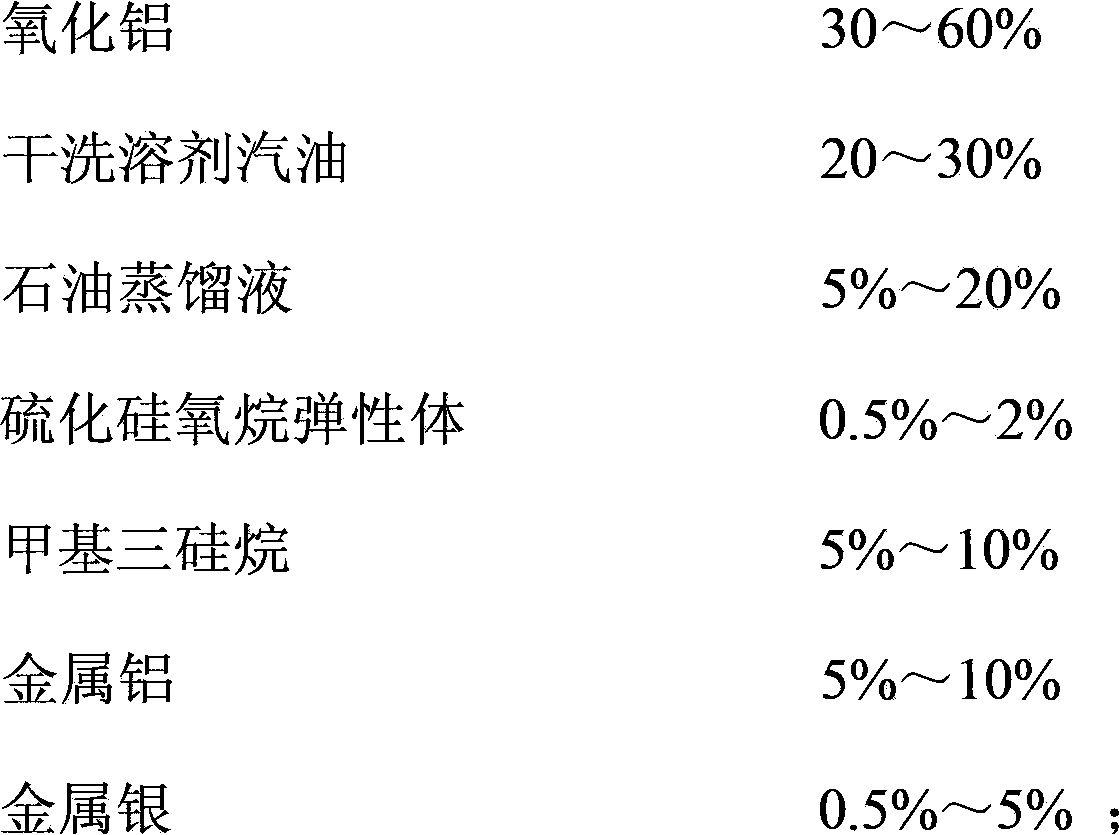

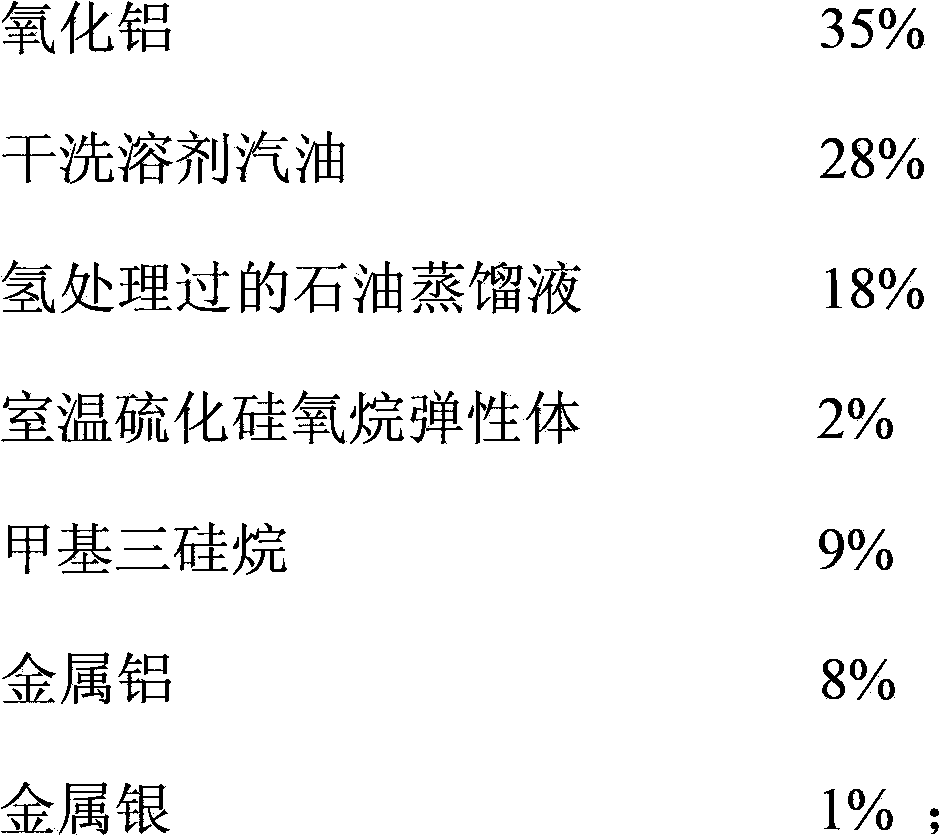

Organosilicon special coating

ActiveCN102766370BNo driftGood electromagnetic shieldingElectrically-conductive paintsMetallic aluminumMetal particle

The invention discloses an organosilicon special coating. The organosilicon special coating comprises the following components in parts by weight: 30-60% of aluminum oxide, 20-30% of Stoddard solvent, 5-20% of petroleum distillate, 0.5-2% of vulcanized silicone elastomer, 5-10% of methyltrisilane, 5-10% of metallic aluminum and 0.5-5% of metallic silver. By adopting the technical scheme provided by the invention, the metal particles can be uniformly distributed on the physical structure surface stabilized by the room temperature-vulcanized silicone elastomer; and no drift phenomenon of the metal particles occurs after a film is formed on the wall. Hence, the product has better electromagnetic shielding and anti-static functions. The coating prepared by using the technical scheme provided by the invention has good wear resistance performance and is convenient for cleaning contaminants. The contents of soluble volatiles, free formaldehyde and soluble lead and the like in the coating are far below the national standard GB18582-2001. The coating is very environmental-friendly and can be used in families.

Owner:西安亨孚防务科技有限责任公司

Method for treating waste liquid containing polyphenyl ether

The invention relates to a method for treating waste liquid containing polyphenyl ether. In the solvent recovery stage in the production process of polyphenyl ether, a certain amount of thick waste solvent containing polyphenyl ether is generated and is very difficult to treat. The invention provides a method for treating the waste liquid. The method comprises the following steps: a) firstly, mixing the viscous waste liquid with a precipitator; b) introducing the mixed solution into a centrifugal separator for separation, and c) after centrifugal separation, enabling the liquid phase to enter a solvent recovery system, and enabling the solid phase to enter a drying machine or an extruder for further removal of the solvent.According to the method, the solvent and high-value components can be recovered to the maximum extent, and zero emission is realized.

Owner:大连中沐化工有限公司

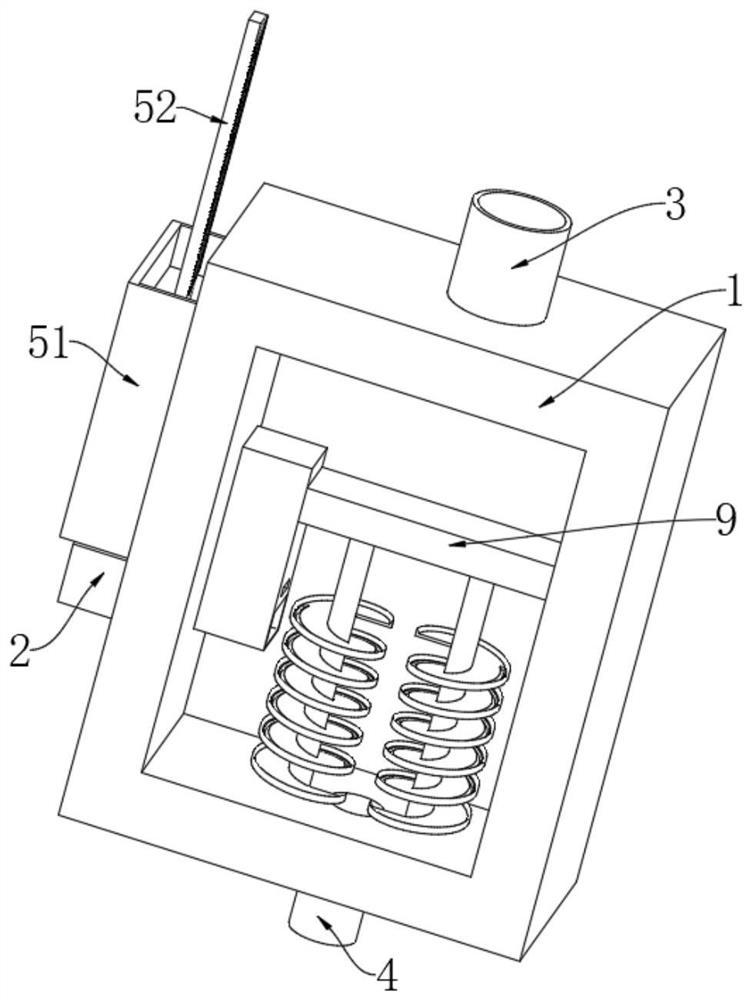

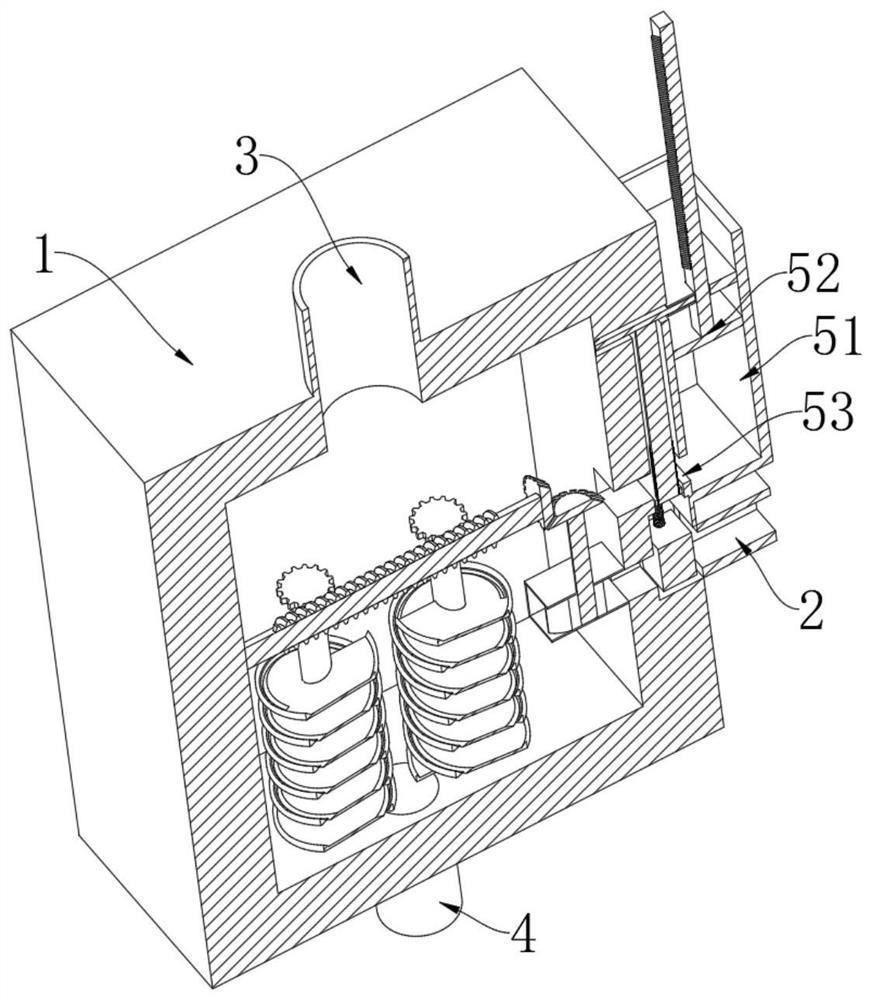

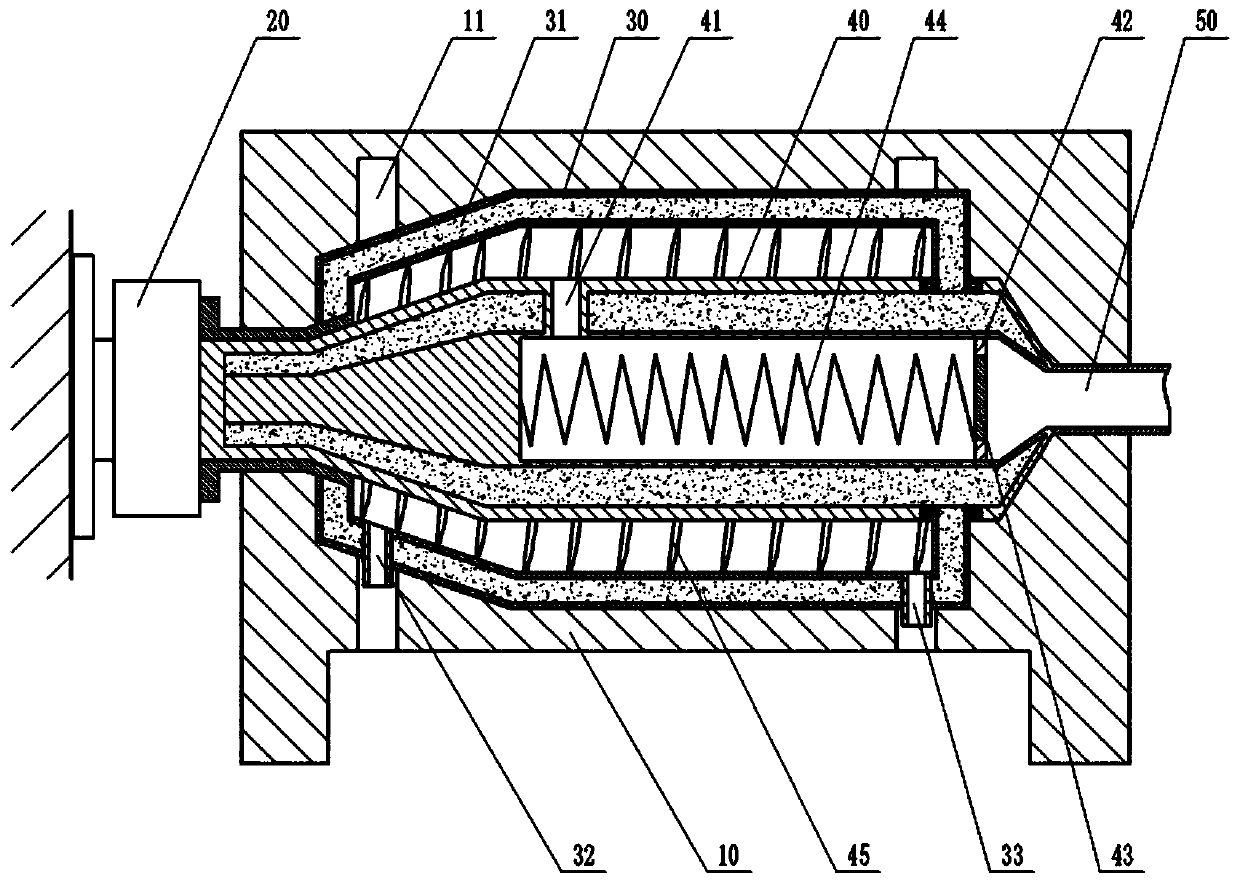

Waste Solvent Recycling Unit

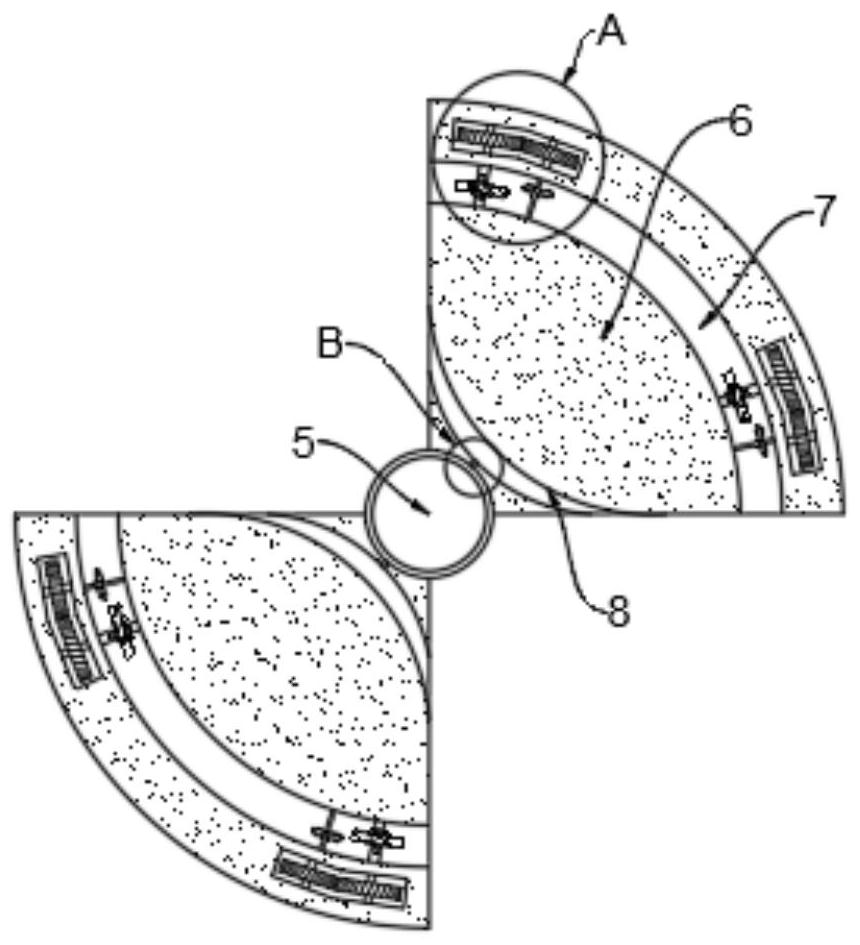

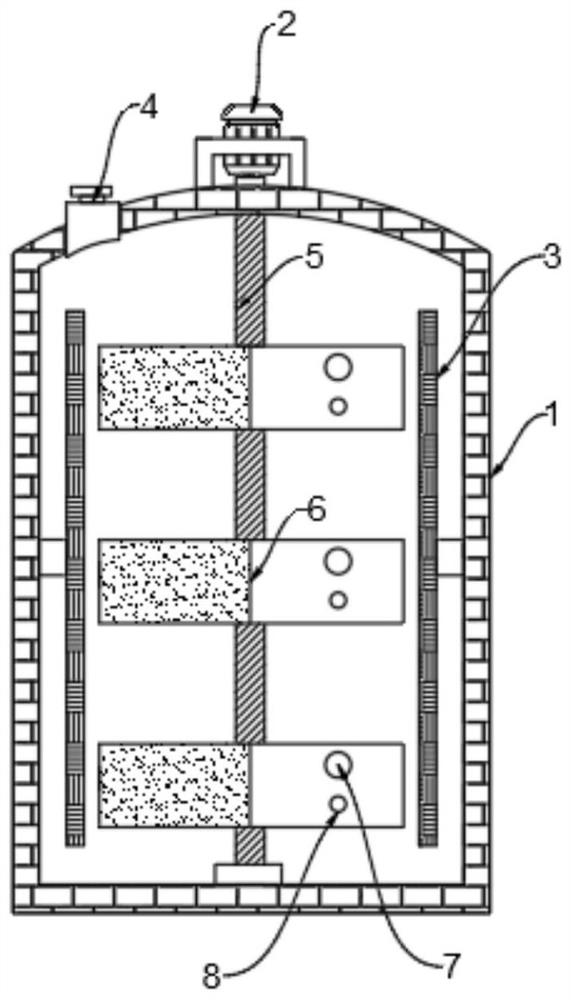

ActiveCN107551590BFully heatedEfficient evaporationCentrifugal force sediment separationDistillation in rotating vesselsSpiral bladeProcess engineering

The invention belongs to the technical field of solvent recycling, and more specifically discloses a waste solvent recycling device. The waste solvent recycling device comprises a raw material feedingunit, a distillation unit, and a condensation unit; the distillation unit comprises a pedestal, a rotating cylinder, a spiral barrel, and a differential mechanism; the side wall of the rotating cylinder and the side wall of the spiral barrel are provided with sandwich layers; the spiral barrel is rotatingly arranged in the rotating cylinder; the sandwich layer on one end of the rotating cylinderis communicated with the sandwich layer of the spiral barrel; the rotating cylinder is rotatingly arranged on the pedestal; one end of the rotating cylinder is designed to be tapered, and the other end is designed to be cylindrical; the external wall of the spiral barrel is provided with spiral blades; one end of the spiral barrel is connected with a feed pipe; a doctor blade is arranged in the spiral barrel in a sliding manner; a pressure valve is arranged on the doctor blade; the spiral barrel and the doctor blade are connected via a spring; the spiral barrel is provided with a discharge hole; one end of the rotating cylinder is provided with a solid output pipe, and the other end is provided with a gas liquid outlet pipe. The waste solvent recycling device is used for recycling waste solvent; in distillation treatment, adhesion of colloid materials onto the internal wall of the distillation unit is avoided, and influences on normal operation of distillation are avoided.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

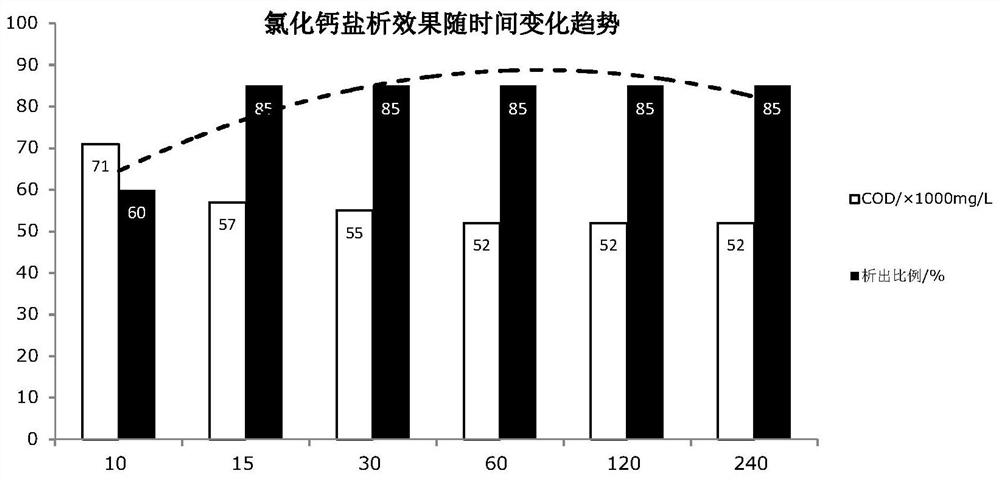

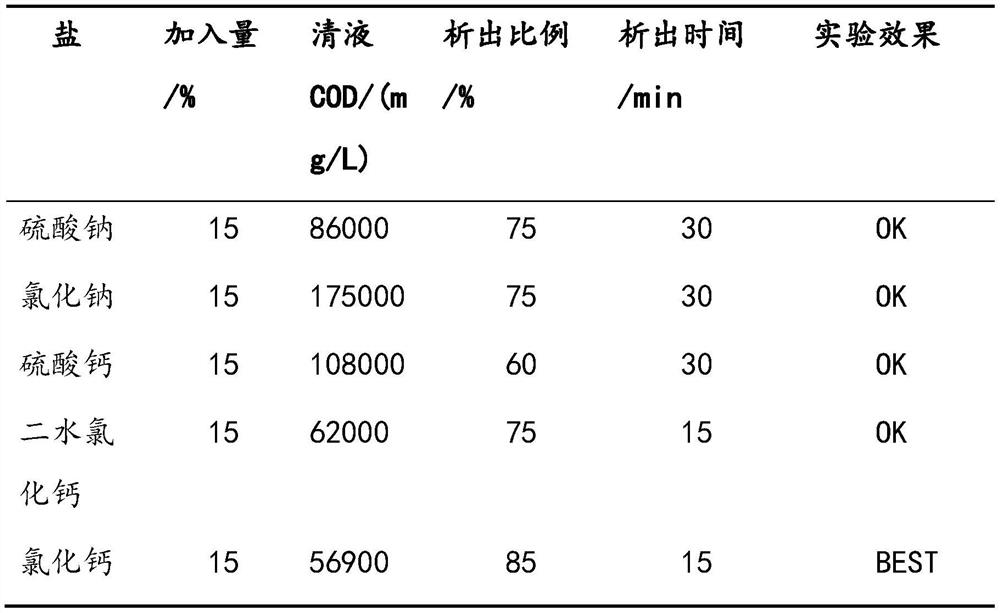

Method and system for treating waste solvent of water-based paint

ActiveCN110028140BImprove efficiencyHigh maintenance costWater/sewage treatment by flocculation/precipitationPolymer resinWastewater

The present application discloses a treatment method for waste solvent of water-based paint, comprising the following steps: collecting and storing, collecting and storing the waste solvent obtained after using a water-based paint cleaning agent; salting out, and transporting the stored waste liquid to a salting-out device , to obtain the supernatant and the lower precipitate by salting out; filter, and transport the supernatant to the filter for filtration. Wherein, the salting-out agent is calcium chloride and the addition of calcium chloride is 5% of the waste solvent. This solution directly precipitates the polymer resin in the water-based paint waste liquid by salting out, and then performs filtration and other treatments to recycle the waste water or discharge it to the outside.

Owner:FAW VOLKSWAGEN AUTOMOTIVE CO LTD

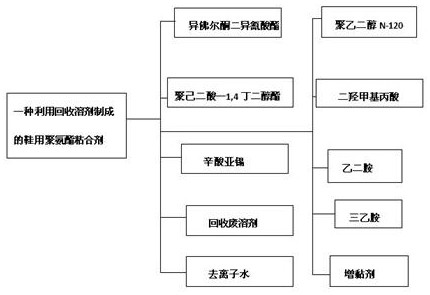

Shoe polyurethane adhesive prepared from recycled solvent and processing method

The invention relates to a shoe polyurethane adhesive prepared from a recycled solvent, which is prepared from the following components: isophorone diisocyanate, poly (1, 4-butylene adipate), polyethylene glycol N-120, dimethylolpropionic acid, stannous octoate, the recycled waste solvent, deionized water, ethylenediamine, triethylamine and a tackifier. The processing method of the shoe polyurethane adhesive prepared from a recycled solvent comprises two steps. The processing process is optimized and screened, is scientific and stable, is easy to operate, and is low in toxicity compared with a traditional solvent type polyurethane adhesive. The waste solvent generated in the preparation process of the aqueous dispersion of the polyurethane adhesive is utilized, so that the effects of saving energy, reducing emission, protecting the environment and recycling resources are achieved. The film-forming property of the adhesive prepared from the recycled solvent is better than that of a pure water-based adhesive, so that the effect of reducing the cost is realized, and the emission of VOC is reduced. On the basis, the method has a good and wide application prospect.

Owner:陈壹铭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of substituted benzo [B] naphthyl benzene [2, 3-D] thiophene derivative and derivative Preparation method of substituted benzo [B] naphthyl benzene [2, 3-D] thiophene derivative and derivative](https://images-eureka.patsnap.com/patent_img/06ca7834-d387-4098-9a82-ea776efaa963/HDA0003574408650000011.png)

![Preparation method of substituted benzo [B] naphthyl benzene [2, 3-D] thiophene derivative and derivative Preparation method of substituted benzo [B] naphthyl benzene [2, 3-D] thiophene derivative and derivative](https://images-eureka.patsnap.com/patent_img/06ca7834-d387-4098-9a82-ea776efaa963/HDA0003574408650000012.png)

![Preparation method of substituted benzo [B] naphthyl benzene [2, 3-D] thiophene derivative and derivative Preparation method of substituted benzo [B] naphthyl benzene [2, 3-D] thiophene derivative and derivative](https://images-eureka.patsnap.com/patent_img/06ca7834-d387-4098-9a82-ea776efaa963/FDA0003574408630000011.png)