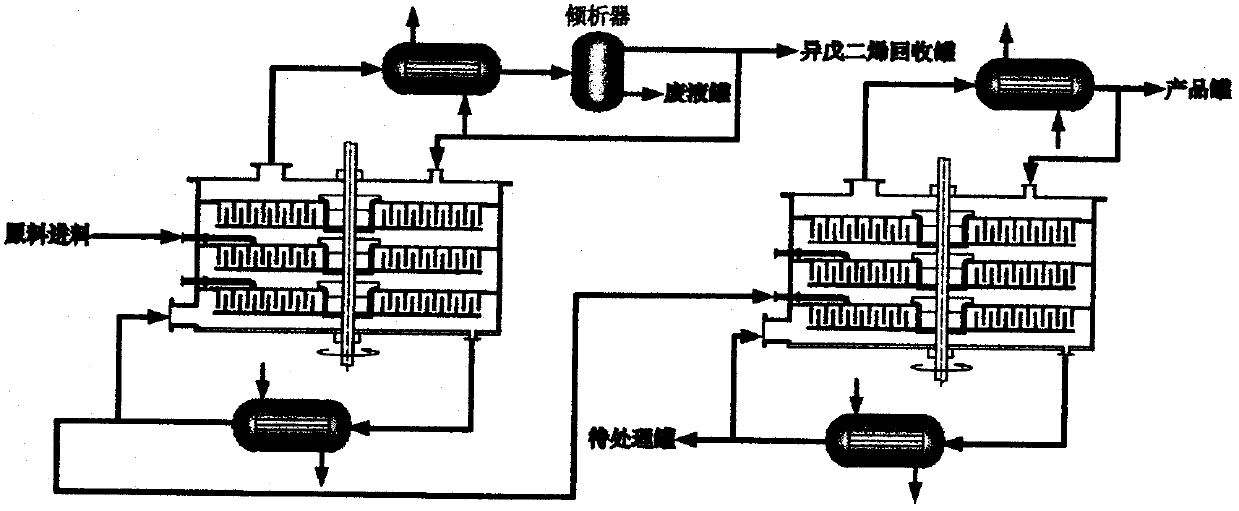

Process for recycling methyl tertbutyl ether-tetrahydrofuran from waste solvent obtained in statins medicine synthetic process by using high-gravity beds

A technology of methyl tertiary butyl ether and tetrahydrofuran, applied in the field of chemical waste solvent recovery, can solve problems such as floor space, energy consumption disadvantage, and cost impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] There is a batch of 50,000 kg of waste solvent, which contains 11.08% of isoprene, 49.56% of methyl tert-butyl ether, 18.12% of tetrahydrofuran, 20.88% of tert-butyl acetate and 0.36% of other impurities as determined by gas chromatography. The water content is 2.17% as measured by a moisture meter. At a rate of 700kg / h, the waste solvent is pumped from the transition feed tank into the first supergravity bed. The turntable speed of the supergravity bed is 1000r / min, the reflux ratio is controlled between 2 and 4, and the temperature at the top of the tower is controlled at 34°C to 35°C. Operating under normal pressure conditions, a mixture of isoprene and water can be obtained at the top of the tower, and the upper layer can obtain isoprene with a purity of 98.26% after decanting. In the composition of the first supergravity bed column liquid, isoprene is 2.85%, methyl tert-butyl ether is 53.97%, tetrahydrofuran is 19.88%, tert-butyl acetate is 22.91%, other impuritie...

example 2

[0018] There is a batch of 42,000 kg of waste solvent, which contains 13.56% isoprene, 42.76% methyl tert-butyl ether, 23.43% tetrahydrofuran, 19.83% tert-butyl acetate and 0.42% other impurities as determined by gas chromatography. The water content is 1.96% as measured by a moisture meter. At a rate of 640kg / h, the waste solvent is pumped from the transition feed tank into the first supergravity bed. The turntable speed of the supergravity bed is 1000r / min, the reflux ratio is controlled between 4 and 6, and the temperature at the top of the tower is controlled at 35°C to 36°C. Operating under normal pressure conditions, a mixture of isoprene and water can be obtained at the top of the tower, and isoprene with a purity of 98.11% can be obtained in the upper layer through decanting. In the composition of the first supergravity bed column liquid, isoprene is 3.02%, methyl tert-butyl ether is 47.52%, tetrahydrofuran is 26.48%, tert-butyl acetate is 22.53%, other impurities are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com