Dynamic separation and recovery device for water-based paint cleaning solvent and driving control method

A technology of separation and recovery, water-based paint, applied in chemical instruments and methods, reflux water treatment, water/sewage treatment, etc., can solve problems such as wasting time, achieve high economic value, high recovery rate, and improve time-consuming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

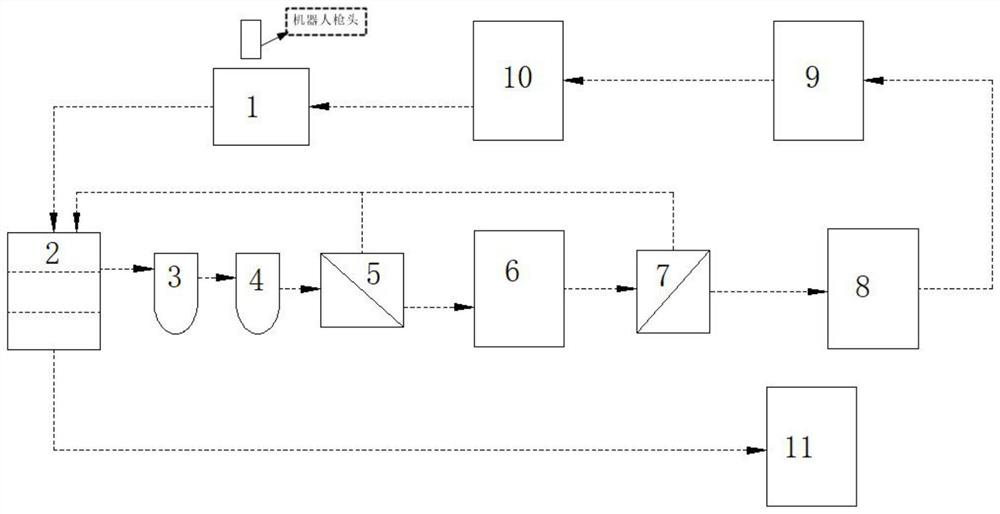

[0029] see figure 1 , in this invention:

[0030] In the automatic spraying process of car paint and other workshops, a large amount of spray paint is attached to the robot gun head, and the cleaning liquid cleans the robot gun head, and the cleaning liquid enters the cleaning toilet 1, and the liquid collected in the cleaning toilet 1 is transferred to the original liquid tank 2 , the solvent cleaning solution enters the stock solution tank 2 for static settlement. After the clear liquid left standing in the raw liquid tank 2 is filtered by the primary filter bag 3, the 5um filter element 4 and the UF membrane 5 [the filtration accuracy of the UF membrane 5 can reach 0.01um], the preliminary clear liquid is transferred to the primary clear liquid tank 6 , and then filtered through the RO membrane 7 [filter precision up to 0.001um], the clear liquid filtered through the RO membrane 7 enters the recovery solution tank 8, and the concentrated liquid filtered out by the UF membr...

Embodiment 2

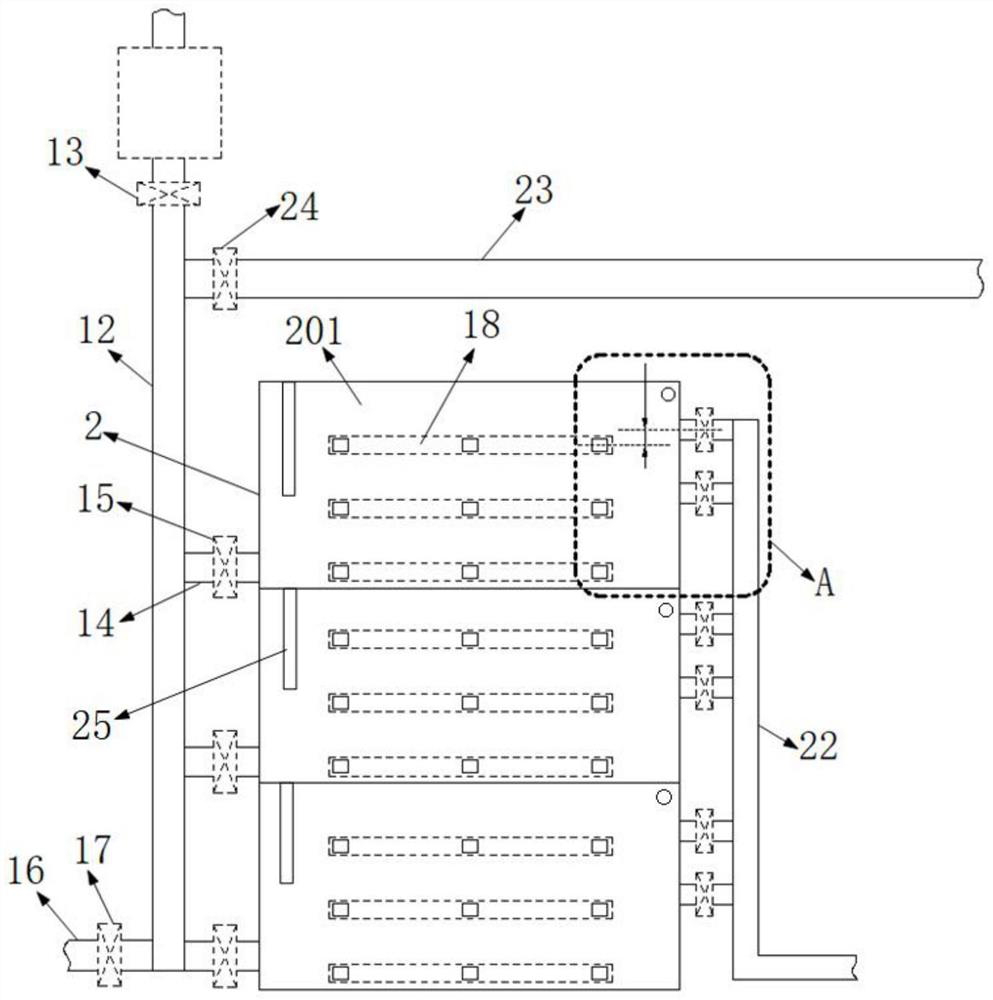

[0034] see figure 1 , figure 2 , image 3 , in this invention:

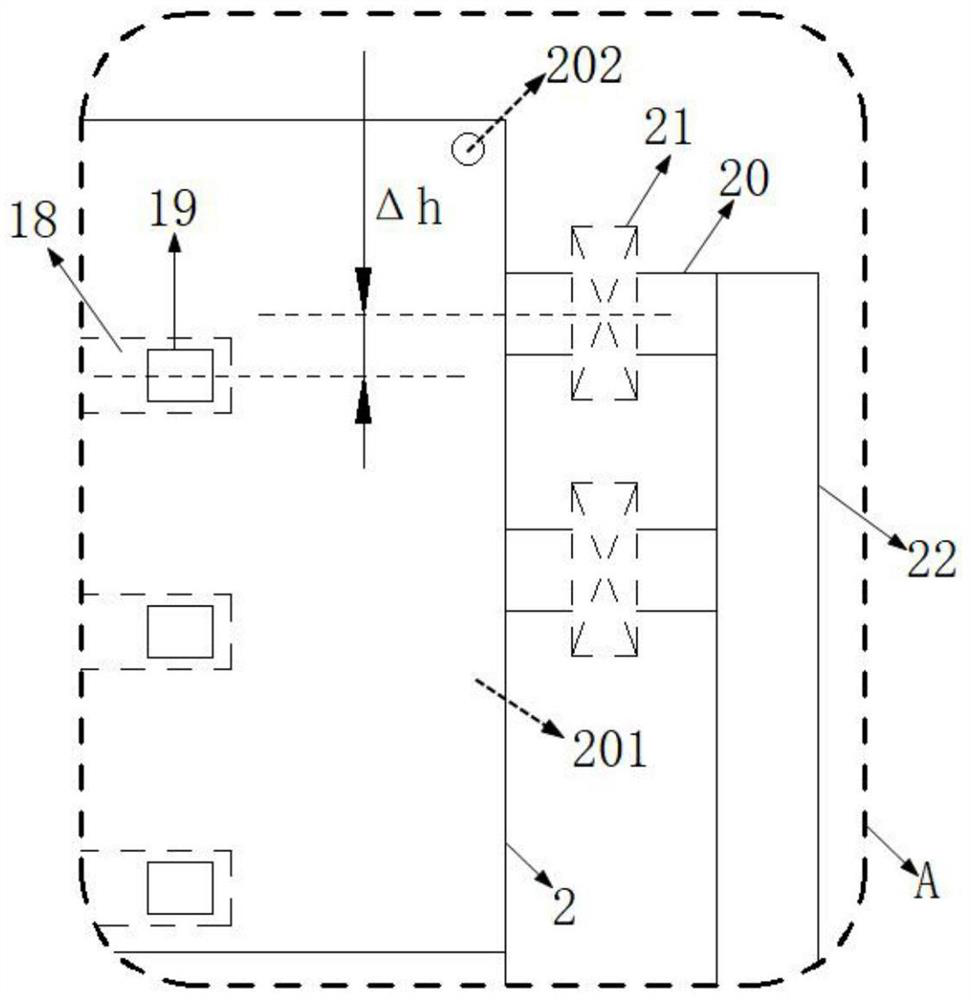

[0035] The stock solution tank 2 is divided into a plurality of separation chambers 201, and each separation chamber 201 is equipped with a multi-layer photoelectric detection belt 18, and a plurality of photoelectric probes 19 are arranged in the photoelectric detection belt 18 of each layer. 19 are neatly arranged at the same height, and the liquid turbidity at each position at the same height in the separation chamber 201 is detected. The turbidity of the liquid at the position of this layer also meets the requirements of the preliminary standing clear liquid.

[0036]One side of the separation chamber 201 is connected with a connecting branch pipe 14 matching the position of the bottom photoelectric detection belt 18, and the other side is connected with a plurality of suction branch pipes 20 matching the position of the non-bottom photoelectric detection belt 18. Note that there is generally one connect...

Embodiment 3

[0039] see figure 2 , image 3 , in this invention:

[0040] The separation chamber 201 of the raw liquid tank 2 is equipped with a liquid level gauge 25 for sensing and detecting the liquid level height in the separation chamber 201. The control system presets the maximum saturation liquid level of the separation chamber 201, and the liquid level gauge 25 detects When the maximum saturated liquid level is reached, the control system isolates the separation chamber 201 from the outside world, and the separation chamber 201 is left to settle.

[0041] The liquid level gauge 25 adopts a non-full-section design, but it needs to measure the liquid level above the bottom photoelectric detection zone 18 to assist in judging whether to close the suction branch pipe 20 at the corresponding height. For example, after the water level has been lower than the suction branch pipe 20 of the topmost position [but not lower than the photoelectric detection zone 18 of the highest level, but...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com