Extraction-rectification recovery method of N-methyl pyrrolidone in waste solvent

A technology of methyl pyrrolidone and recovery method, which is applied in the field of chemical waste solvent recovery, can solve the problems of reducing energy consumption, and achieve the effect of green process and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

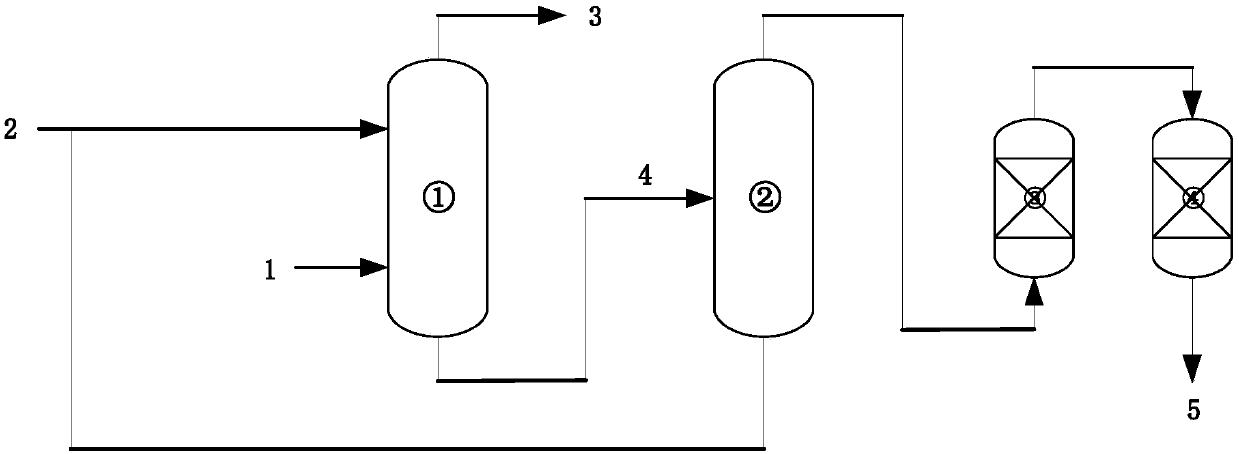

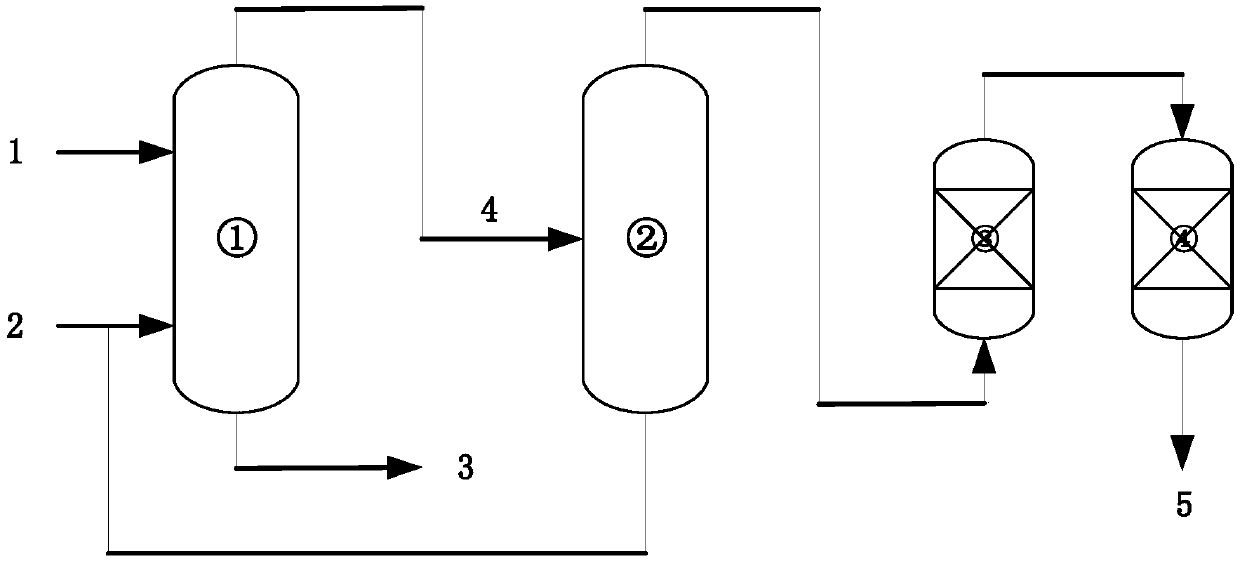

Method used

Image

Examples

Embodiment 1

[0028] A batch of spinning waste solvent, which contains 2% N-methylpyrrolidone after determination, is injected from the upper feed port of the rotary disk sieve plate extraction tower with a flow rate of 20ml / min. With octanoic acid as the extractant, the flow rate is set at 10ml / min, and it enters from the lower feeding port of the rotary disk sieve plate extraction tower. The speed of the turntable was set at 10 r / min, the extraction temperature was 25° C., and the extraction phase was obtained at the top of the extraction tower. The extraction phase enters from the middle of the rectification tower, the pressure is set to 0.75atm, the reflux ratio is set to 1, the temperature at the top of the tower is controlled at 190.8°C, and the top fraction at this temperature is collected. Finally, the obtained overhead fraction is sequentially passed through the decolorization tower and the dehydration tower to finally obtain the N-methylpyrrolidone product. The N-methylpyrrolidone...

Embodiment 2

[0030]A batch of spinning waste solvent, which contains 5% N-methylpyrrolidone after determination, is injected from the upper feed port of the rotary disk sieve plate extraction tower with a flow rate of 20ml / min. With octanoic acid as the extractant, the flow rate is set at 20ml / min, and it enters from the lower feeding port of the rotary disk sieve plate extraction tower. The speed of the turntable was set at 20 r / min, the extraction temperature was 25° C., and the extraction phase was obtained at the top of the extraction tower. The extraction phase enters from the middle of the rectification tower, the pressure is set to 0.75atm, the reflux ratio is set to 1, the temperature at the top of the tower is controlled at 190.8°C, and the top fraction at this temperature is collected. Finally, the obtained overhead fraction is sequentially passed through the decolorization tower and the dehydration tower to finally obtain the N-methylpyrrolidone product. The N-methylpyrrolidone ...

Embodiment 3

[0032] A batch of spinning waste solvent, which contains 20% N-methylpyrrolidone after determination, is injected from the upper feed port of the rotary disk sieve plate extraction tower with a flow rate of 20ml / min. With octanoic acid as extractant, the flow rate is set as 40ml / min, and enters from the lower feed port of the rotary disk sieve plate extraction tower. The speed of the turntable was set at 40 r / min, the extraction temperature was 25° C., and the extraction phase was obtained at the top of the extraction tower. The extraction phase enters from the middle of the rectification tower, the pressure is set to 0.75atm, the reflux ratio is set to 1, the temperature at the top of the tower is controlled at 190.8°C, and the top fraction at this temperature is collected. Finally, the obtained overhead fraction is sequentially passed through the decolorization tower and the dehydration tower to finally obtain the N-methylpyrrolidone product. The N-methylpyrrolidone has a pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com