Method and equipment for recovering and purifying MTBE (methyl tert-butyl ether) waste solvent generated by synthesizing drug intermediate

A technology for synthesizing drugs and purification methods, applied in the fields of ether preparation, ether separation/purification, organic chemistry, etc., which can solve the problems of greatly reducing environmental pressure, etc., and achieve the effects of reducing pollution and saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

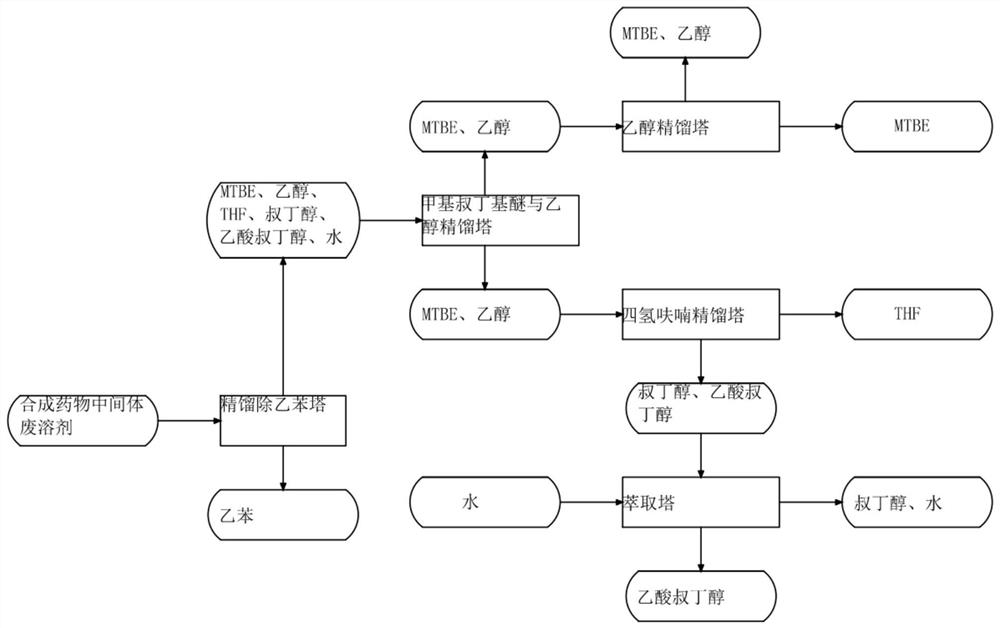

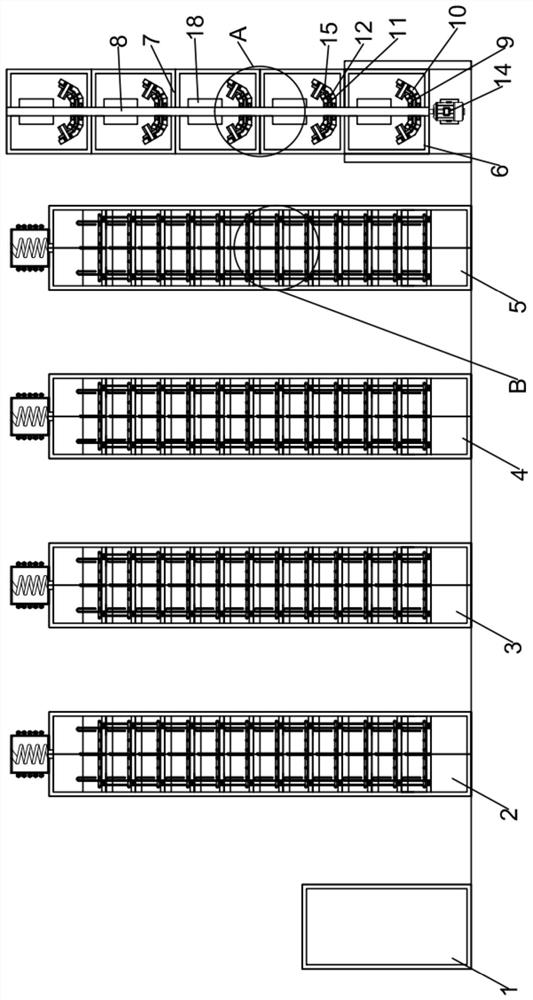

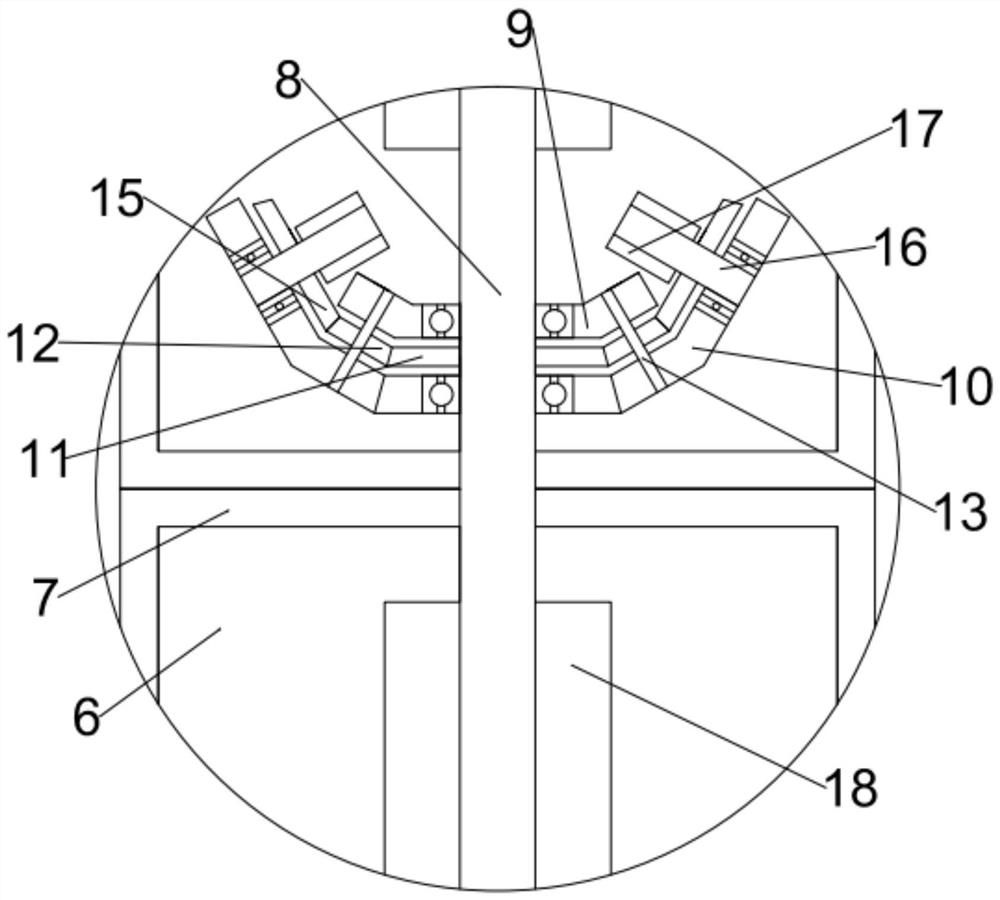

[0044] Embodiment 1: Take the synthetic drug intermediate waste solvent from the waste liquid tank, add it to the rectification and removal of ethylbenzene tower, rectify under normal pressure, the heating temperature is 145 ° C, the reflux ratio is controlled at 15: 1, and the top material is taken out. When the temperature at the top of the tower is 136°C, the rectified liquid is tested to be qualified and packed into tanks, filled with nitrogen for storage, and then the industrial grade ethylbenzene with a content ≥ 99.8% can be obtained. Add methyl tert-butyl ether and ethanol to the rectification tower, rectify under normal pressure, heat at 105°C, control the reflux ratio to 20:1, and extract methyl tert-butyl ether and ethanol at the top of the rectification tower with a temperature of 50 The mixture of methyl tert-butyl ether and ethanol at ~56°C, the mixture of tetrahydrofuran, tert-butanol, and tert-butyl acetate remaining in the distillation column of methyl tert-but...

Embodiment 2

[0045]Example 2: Take the waste solvent of synthetic drug intermediates from the waste liquid tank, add it to the rectification and removal of ethylbenzene tower, rectify under normal pressure, the heating temperature is 145 ° C, the reflux ratio is controlled at 10: 1, and the top material is taken out. When the temperature at the top of the tower is 136°C, the rectified liquid is tested to pass the test and filled with nitrogen for storage. The industrial grade ethylbenzene with a content of ≥99.8% can be obtained. Add methyl tert-butyl ether and ethanol to the rectification tower, rectify under normal pressure, heat at 105°C, control the reflux ratio of 15:1, and extract methyl tert-butyl ether when the tower top temperature is 50-56°C , ethanol mixture, the mixture of tetrahydrofuran, tert-butanol, and tert-butyl acetate remaining in the tower kettle, the above-mentioned components extracted from the top of the tower are added to the ethanol rectification tower, rectified u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com