Waste solvent treatment method

A treatment method and technology for waste solvents, which are applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., can solve problems such as waste of waste solvent components, reduce CO2 emissions, avoid negative effects, and be beneficial to the environment. protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

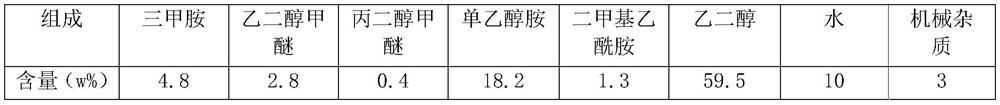

[0024] Table 1: Composition of waste solvents in an electronics factory (the components here are the actual waste solvent detection and analysis results)

[0025]

[0026] Table 1 shows the waste solvent composition of an electronics factory, and the ratio of each component obtained after detection and analysis.

[0027] The above-mentioned waste solvent is processed by this method, and its concrete steps are:

[0028] (1) vacuum distillation

[0029] The cleaned waste solvent is continuously pumped into the vacuum thin film evaporator at a feed rate of 1000kg / h. Specifically, a scraper thin film evaporator is used. The internal vacuum of the scraper thin film evaporator is 10kPa. Feed, scraper film evaporator jacket heating adopts 0.8MPa steam heating. The waste solvent vapor comes out from the top of the scraped thin film evaporator, and after being condensed by the top condenser of the scraped thin film evaporator (the temperature is controlled at 50°C), it enters the ...

Embodiment 2

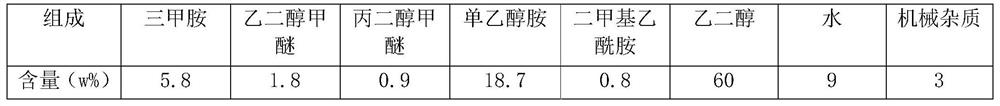

[0043] Table 4: Composition of waste solvents in an electronics factory (the components here are the actual waste solvent detection and analysis results)

[0044]

[0045] Table 4 shows the waste solvent composition of an electronics factory, and the ratio of each component obtained after detection and analysis.

[0046] The above-mentioned waste solvent is processed by this method, and its concrete steps are:

[0047] (1) vacuum distillation

[0048] The cleaned waste solvent is continuously pumped into the vacuum thin film evaporator at a feed rate of 2000kg / h. Specifically, a scraper thin film evaporator is used. The internal vacuum of the scraper thin film evaporator is 30kPa. Feed, scraper film evaporator jacket heating adopts 0.8MPa steam heating. The waste solvent vapor comes out from the top of the scraped thin film evaporator, and after being condensed by the top condenser of the scraped thin film evaporator (the temperature is controlled at 60°C), it enters the ...

Embodiment 3

[0063] Table 7: Composition of waste solvents in an electronics factory (the components here are the actual waste solvent detection and analysis results)

[0064]

[0065] The waste solvent in above-mentioned table 7 is processed by this method, and its concrete steps are:

[0066] (1) vacuum distillation

[0067] The cleaned waste solvent is continuously pumped into the vacuum thin film evaporator at a feed rate of 1000kg / h. Specifically, a scraper thin film evaporator is used. The internal vacuum of the scraper thin film evaporator is 20kPa. Feed, scraper film evaporator jacket heating adopts 0.8MPa steam heating. The waste solvent vapor comes out from the top of the scraped thin film evaporator, and after being condensed by the top condenser of the scraped thin film evaporator (the temperature is controlled at 40°C), it enters the solvent receiving intermediate tank, and part of the uncondensed non-condensable gas (mainly containing trimethylamine solvent) Enter the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com