Method and system for treating waste solvent of water-based paint

A treatment method and a treatment system technology, applied in the field of water-based paint waste solvent treatment, can solve the problems of numerous steps and slow operation, and achieve the effects of reducing COD, improving efficiency and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

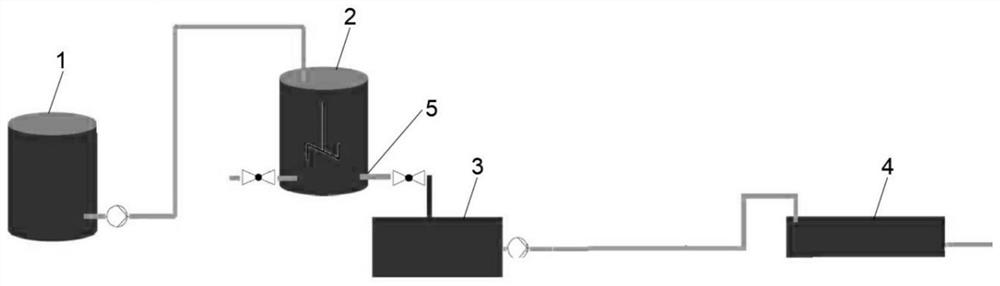

[0029] In order to further elaborate the technical means and effects that the present invention adopts for reaching the intended invention purpose, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure, features and effects of the present invention are described in detail as follows:

[0030] A treatment method for water-based paint waste solvent, comprising the following steps:

[0031] S1. Collect and store, collect and store the waste solvent obtained after using the water-based paint cleaning agent;

[0032] S2, salting out, transporting the stored waste liquid to a salting out device, and obtaining a supernatant and a lower layer of precipitation through salting out;

[0033] S3, filtering, transporting the supernatant to the filter for filtering.

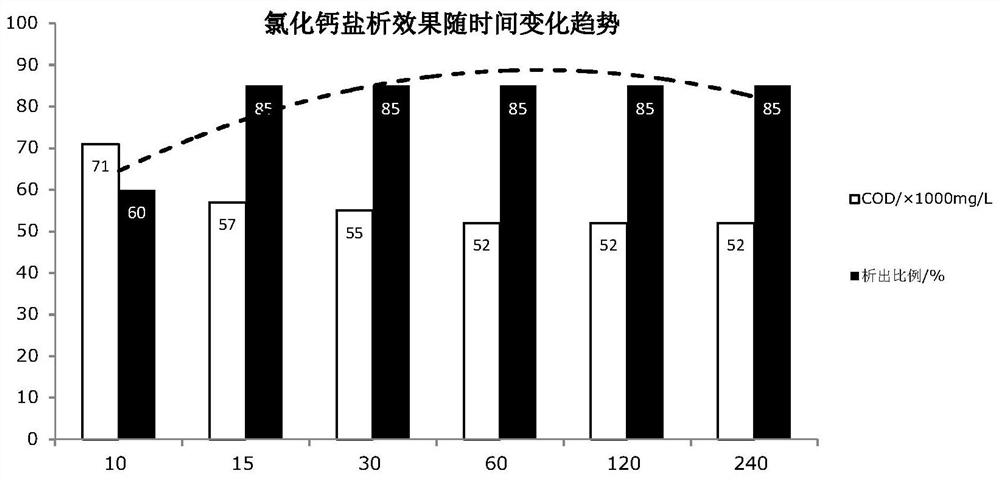

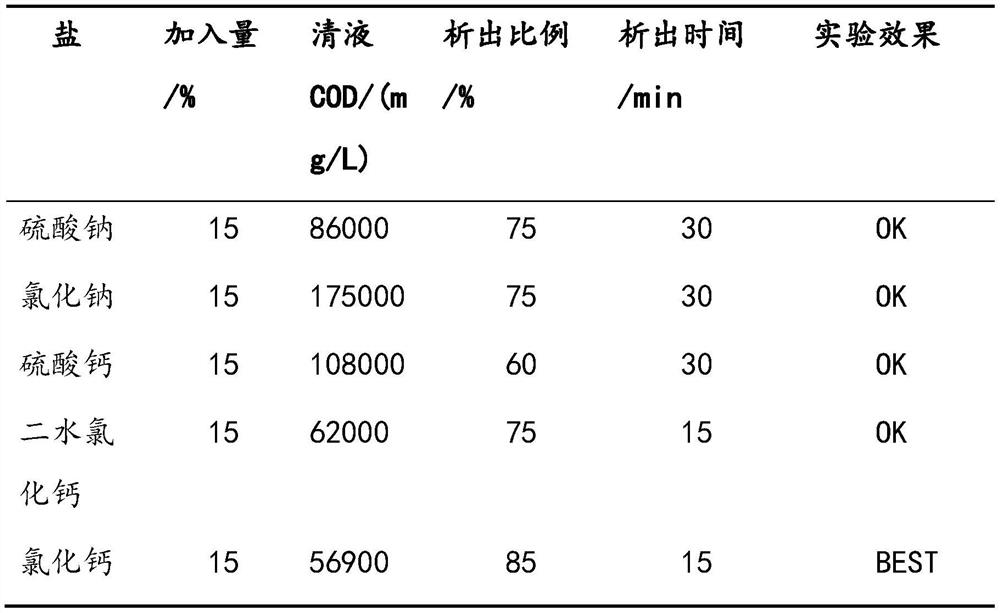

[0034] This scheme directly precipitates the polymer resin, pigment and filler in the water-based paint waste liquid by salting out, and it is extremely convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com