Method and equipment for recovering and purifying methyl tert-butyl ether waste solvent

A technology of methyl tert-butyl ether and purification method, which is applied in the fields of ether preparation, ether separation/purification, organic chemistry, etc., can solve problems such as limiting the recovery of solvent outlets, achieve stable operation, save production costs, and achieve good quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

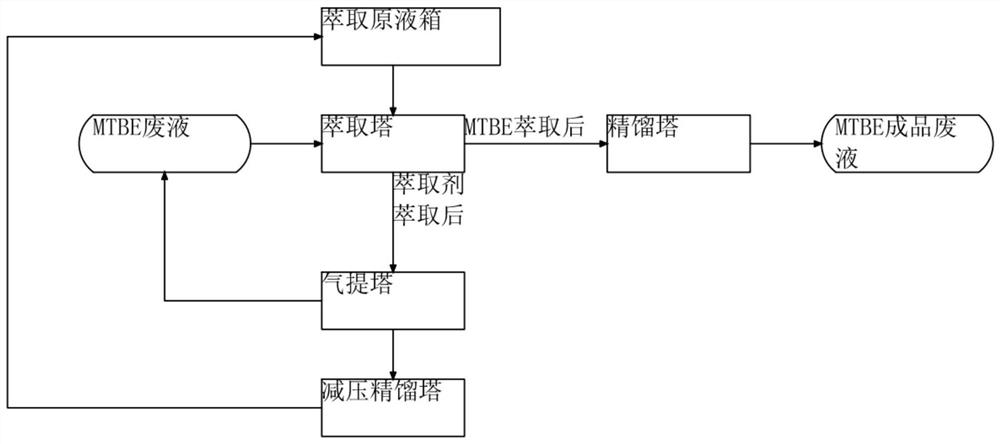

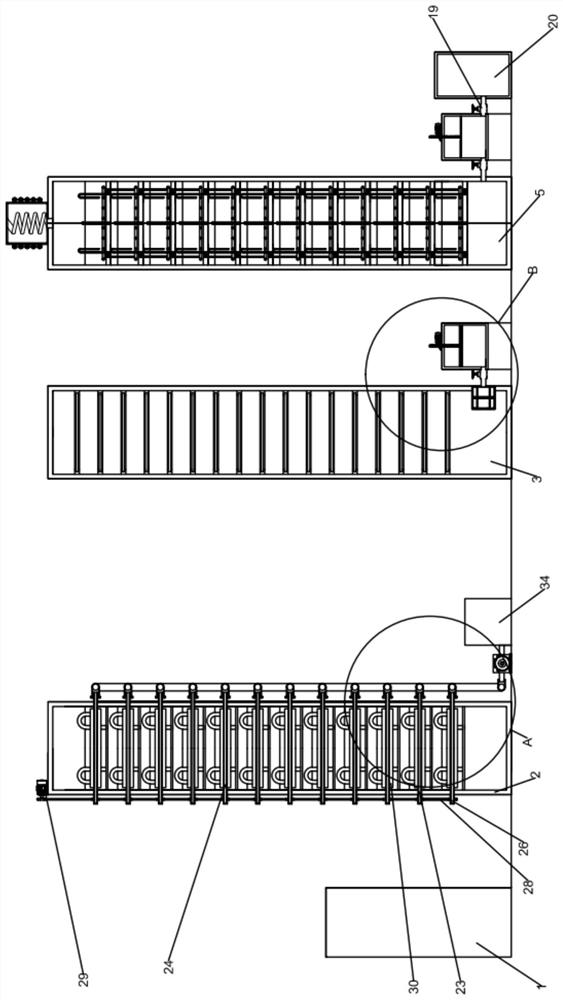

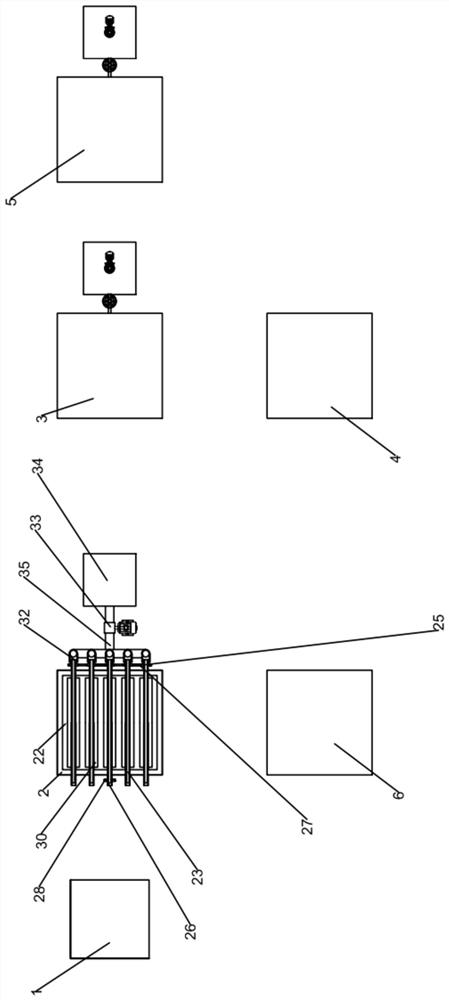

[0044] Embodiment 1: Take the waste material containing 95% methyl tert-butyl ether from the waste liquid tank 1, add ethylene glycol with 1 times the volume of the waste material therein, and drain it into the extraction tower 2 for extraction operation. The methyl tert-butyl ether is diverted to the rectification tower 4 for rectification, and the rectification effluent is tested to be qualified and filled with nitrogen for preservation, so as to obtain industrial-grade methyl tert-butyl ether with a purity of ≥99.9% (wt). After the extracted extractant is preheated to 108°C, the low-pressure steam is introduced to carry out air stripping, and the methyl tert-butyl ether and low-boiling impurities are removed, and the above-mentioned extractant is diverted to the vacuum rectification tower 5 for vacuum rectification. Water is removed, and the extractant is recovered, and the purity of the extractant is ≥99.9%. The extraction agent is used in a circular manner, running throug...

Embodiment 2

[0045] Embodiment 2: Take the waste material containing 90% methyl tert-butyl ether from the waste liquid tank 1, add ethylene glycol with 3 times the volume of the waste material therein, and drain it into the extraction tower 2, and carry out the extraction operation. The methyl tert-butyl ether is diverted to the rectification tower 4 for rectification, and the rectification effluent is tested to be qualified and filled with nitrogen for preservation, so as to obtain industrial-grade methyl tert-butyl ether with a purity of ≥99.9% (wt). After the extracted extractant is preheated to 105°C, the low-pressure steam is introduced to carry out air stripping, and the methyl tert-butyl ether and low-boiling impurities are removed, and the above-mentioned extractant is diverted to the vacuum rectification tower 5 for vacuum rectification, Water is removed, and the extractant is recovered, and the purity of the extractant is ≥99.9%. The extractant is recycled.

[0046] The technica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com