Method for recycling and purifying a mixed waste liquid of methylethanolamine and diethylene glycol monobutyl ether in the electronic industry

A technology of diethylene glycol monobutyl ether and ethylene glycol monobutyl ether, which is applied in the field of recycling and purifying mixed waste liquid of methyl ethanolamine and diethylene glycol monobutyl ether in the electronics industry, can solve environmental pollution, resource waste, Distillation speed is effectively improved to achieve the effect of reducing pollution level and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

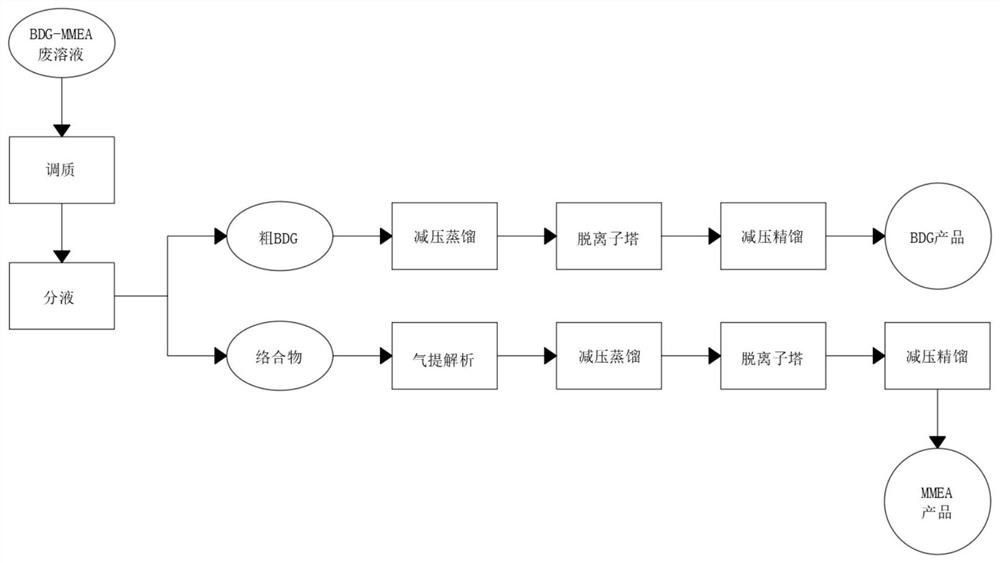

[0041] A method for recovering and purifying the mixed waste liquid of methylethanolamine and diethylene glycol monobutyl ether in the electronics industry, characterized in that the step of extracting comprises:

[0042] Get waste material diethylene glycol monobutyl ether 60-65% and methylethanolamine stripping liquid 35-40%, to wherein continue to pass into carbon dioxide, to the polarity and pH value of waste material diethylene glycol monobutyl ether and methylethanolamine Adjust the pH value to be within the range of 6 to 8; and react with impurities such as waste diethylene glycol monobutyl ether and organic bases in methyl ethanolamine to form complexes and appear with diethylene glycol monobutyl ether Liquid separation.

[0043] The diethylene glycol monobutyl ether and methyl ethanolamine obtained by tempering are separated to obtain the upper layer diethylene glycol monobutyl ether and the lower layer methyl ethanolamine.

[0044] Preheat the methyl ethanolamine in...

Embodiment 2

[0051] A method for recovering and purifying the mixed waste liquid of methylethanolamine and diethylene glycol monobutyl ether in the electronics industry, characterized in that the step of extracting comprises:

[0052] Get waste diethylene glycol monobutyl ether and methylethanolamine stripping liquid, add wherein the hydrochloric acid solution that volume concentration is 35%, the polarity and the pH value of waste material diethylene glycol monobutyl ether and methylethanolamine are adjusted, The pH value is controlled within the range of 6-8; and it reacts with impurities such as waste diethylene glycol monobutyl ether and organic bases in methyl ethanolamine to form a complex and separate liquid with diethylene glycol monobutyl ether.

[0053] The diethylene glycol monobutyl ether and methyl ethanolamine obtained by tempering are separated to obtain the upper layer diethylene glycol monobutyl ether and the lower layer methyl ethanolamine.

[0054] The methyl ethanolamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com