Waste Solvent Recycling Unit

A technology of recycling and waste solvent, which is applied in the direction of distillation in a rotating container and separation of sediments by centrifugal force, etc., which can solve the problems of inoperability of the device, pollution of the environment, waste of petroleum resources, etc., to prevent internal blockage of the device and simplify the processing steps , the effect of low solid moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

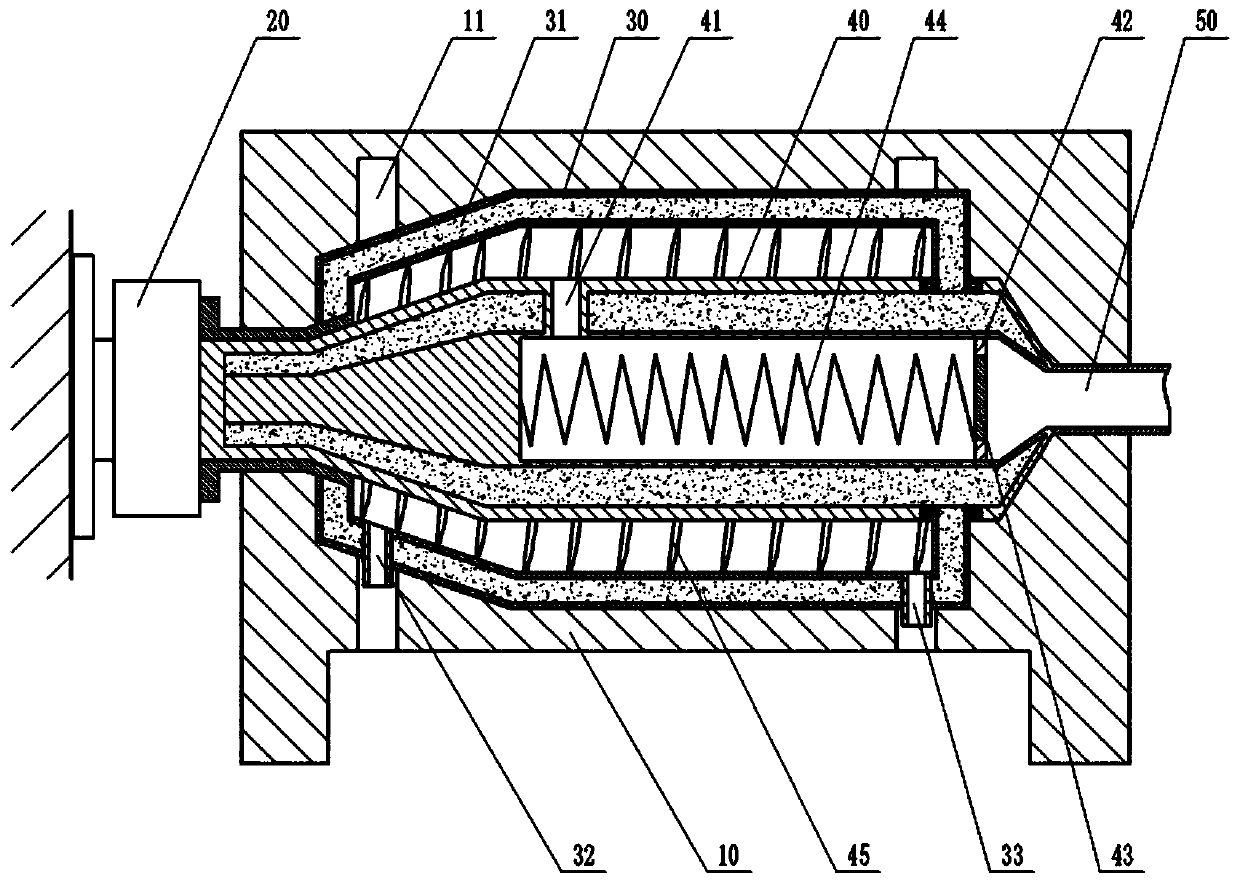

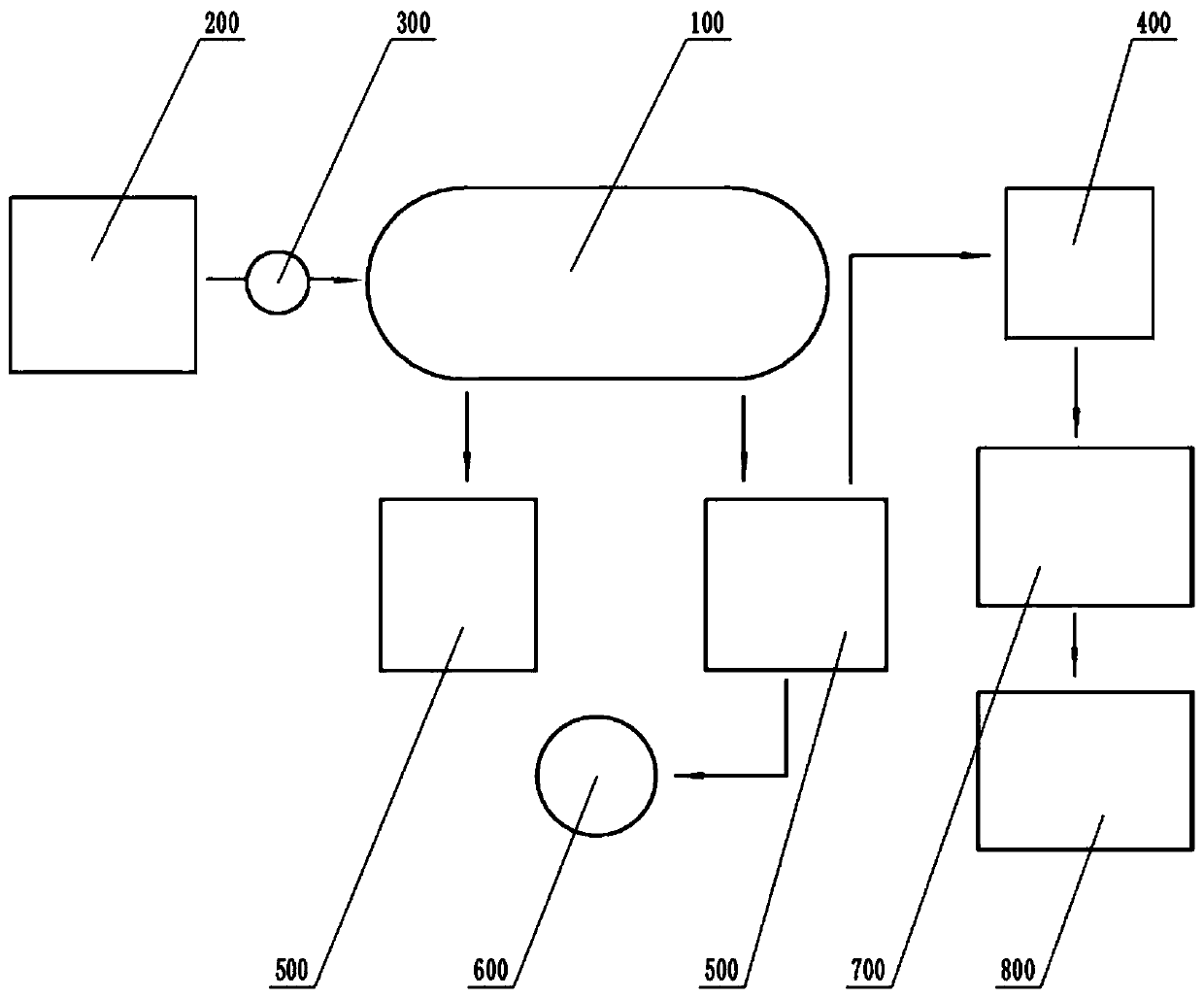

[0020] Instructions attached Figures 1 to 2 Reference numerals in include: distillation unit 100, raw material feeding unit 200, delivery pump 300, condensation unit 400, waste recovery tank 500, vacuum pump 600, slow flow tank 700, solvent recovery tank 800, base 10, annular tank 11. Differential 20, drum 30, heating oil 31, solid output pipe 32, gas-liquid output pipe 33, spiral drum 40, outlet 41, scraper 42, pressure valve 43, spring 44, spiral blade 45, inlet Material tube 50.

[0021] like figure 1 , figure 2 As shown, the waste solvent recycling device includes a raw material feeding unit 200, a distillation unit 100, a condensation unit 400 and a slow flow tank 700, the raw material feeding unit 200 stores waste solvent to be treated, and the raw material feeding unit 200 waste solvent passes through The transport pump 300 transports the liquid into the dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com