A method for purifying pgmea from pgmea waste liquid

A technology for waste liquid and solid waste, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid esters, etc., can solve the problems of large steam consumption, high treatment cost, and narrow application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: PGMEA waste liquid, components: PGMEA: 72.66%, PGME: 14%, cyclohexanone 5.27%, moisture 1.52%, and other impurities 6.55%, etc.

[0015] Steps:

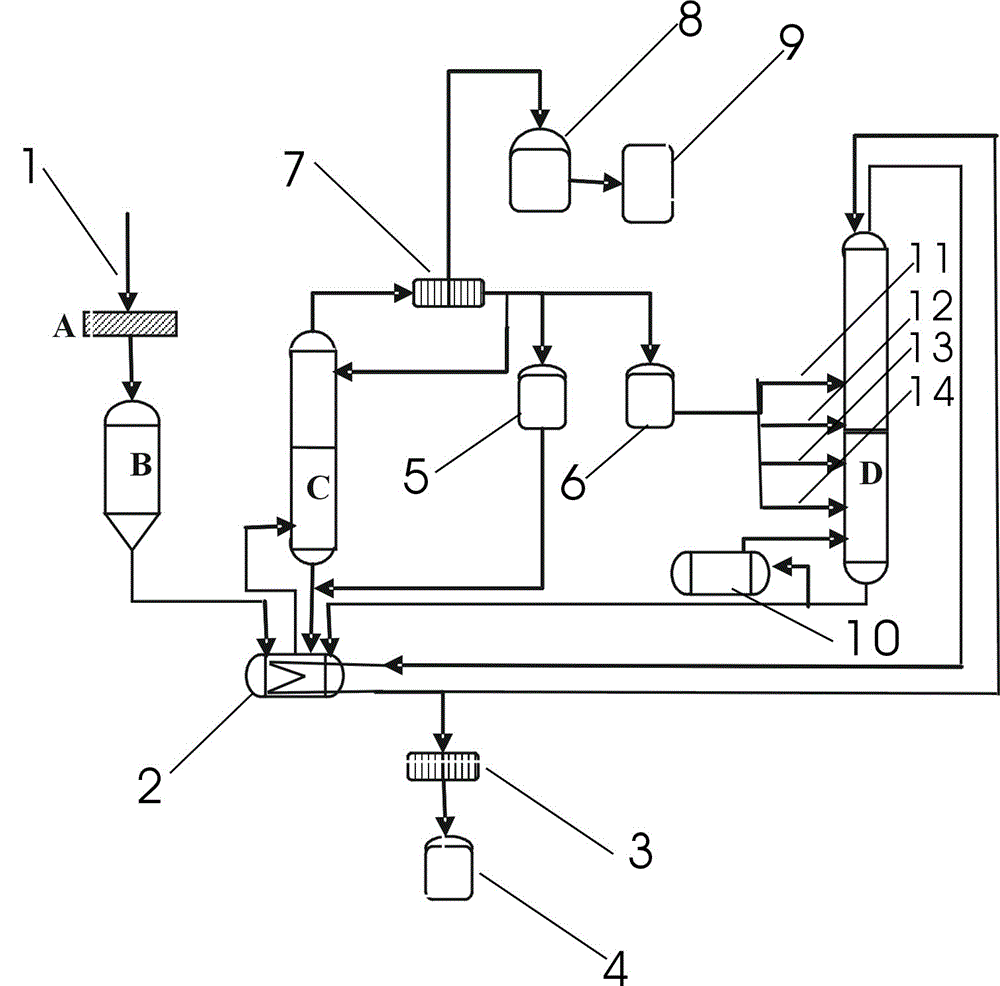

[0016] (1) After the waste PGMEA solution is filtered through filter A to remove large solid waste, it enters the raw material settling tank B to remove settleable solid impurities.

[0017] (2) PGMEA waste liquid through filtration and sedimentation enters distillation tower C, adopts 7~

[0018] The 9-meter-high orifice corrugated packing with strong anti-fouling ability, after the distillation kettle is heated by 0.6MPa saturated steam, the vacuum degree is controlled at -0.092MPa~-0.080MPa, the rising steam in the kettle enters the distillation tower C, and is adjusted by adjusting the reflux The ratio is 2 to 4:1, and the rising steam temperature of the distillation tower is controlled at 45°C to 50°C to distill out cyclohexanone and water. The temperature at the top of the distillation tower rises to 110°C...

Embodiment 2

[0021] Example 2: PGMEA waste liquid, components: PGMEA: 65.72%, PGME: 8.6%, 3-ethoxy ethyl propionate 14%, 3-methoxy-1-butanol acetate 2.5%, moisture 1.52%, and Other impurities 7.66%, etc.

[0022] Steps:

[0023] (1) After the waste PGMEA solution is filtered through filter A to remove large solid waste, it enters the raw material settling tank B to remove settleable solid impurities;

[0024] (2) After filtering and settling, the PGMEA waste liquid enters the distillation tower C. In this embodiment, a 7-10 meter high orifice corrugated packing with strong anti-fouling ability is used in the tower. After the distillation kettle is heated by 0.6MPa saturated steam , the rising steam in the kettle enters the distillation tower C, and the vacuum degree is controlled at -0.090MPa~-0.085MPa. By adjusting the reflux ratio of 3~5:1, the temperature of the distillation tower top is controlled to 90°C~120°C, and the crude product PGMEA is distilled;

[0025] (3) The crude produ...

Embodiment 3

[0027] Example 3: PGMEA waste liquid, components: PGMEA: 70.57%, xylene 10.85%, water 8.01%, 2-butoxyethanol 2.65%, and other impurities 7.92%.

[0028] Steps:

[0029] (1) After the waste PGMEA solution is filtered through filter A to remove large solid waste, it enters the raw material settling tank B to remove settleable solid impurities;

[0030] (2) The filtered and settled PGMEA waste liquid enters the distillation tower C. In this embodiment, a 7-9 meter high orifice corrugated packing with strong anti-fouling ability is used in the tower. After the distillation kettle is heated by 0.6MPa saturated steam , the vacuum degree is controlled at -0.095MPa~-0.090MPa, the rising steam in the kettle enters the distillation tower C, by adjusting the reflux ratio of 3 to 5:1, the temperature of the rising steam in the distillation tower is controlled at 50~55°C, and xylene and water are evaporated . The temperature at the top of the distillation tower rises to 110°C, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com