Method and equipment for purifying ethanolamine and diethylene glycol monobutyl ether in electronic waste solution

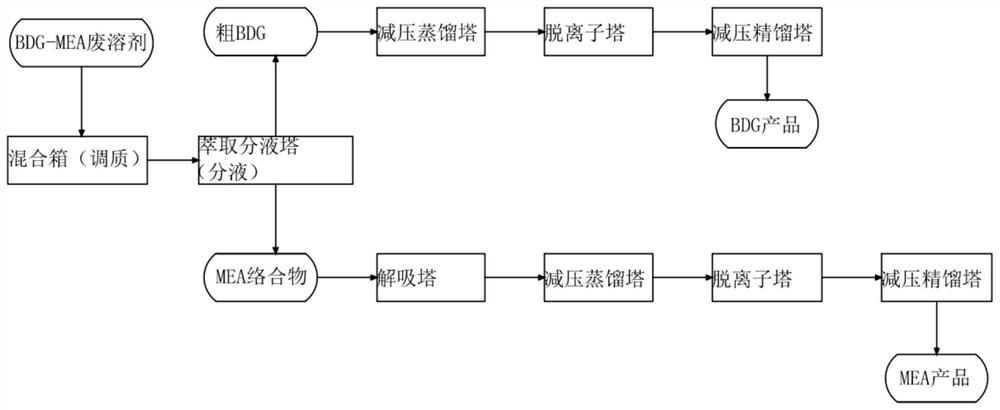

A technology of diethylene glycol monobutyl ether and ethylene glycol monobutyl ether is applied in the field of purification of ethanolamine and diethylene glycol monobutyl ether in electronic waste solution, which can solve the problem that the quality of recovered products cannot reach photoelectric reuse and product recovery. It can save production costs and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

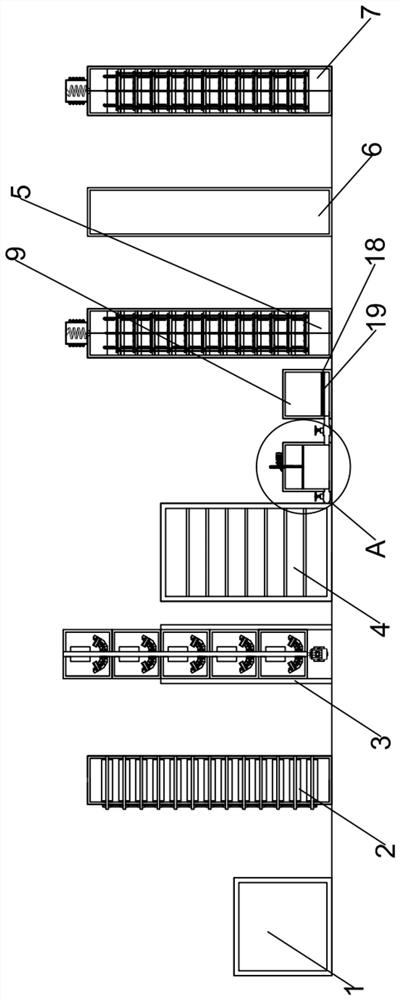

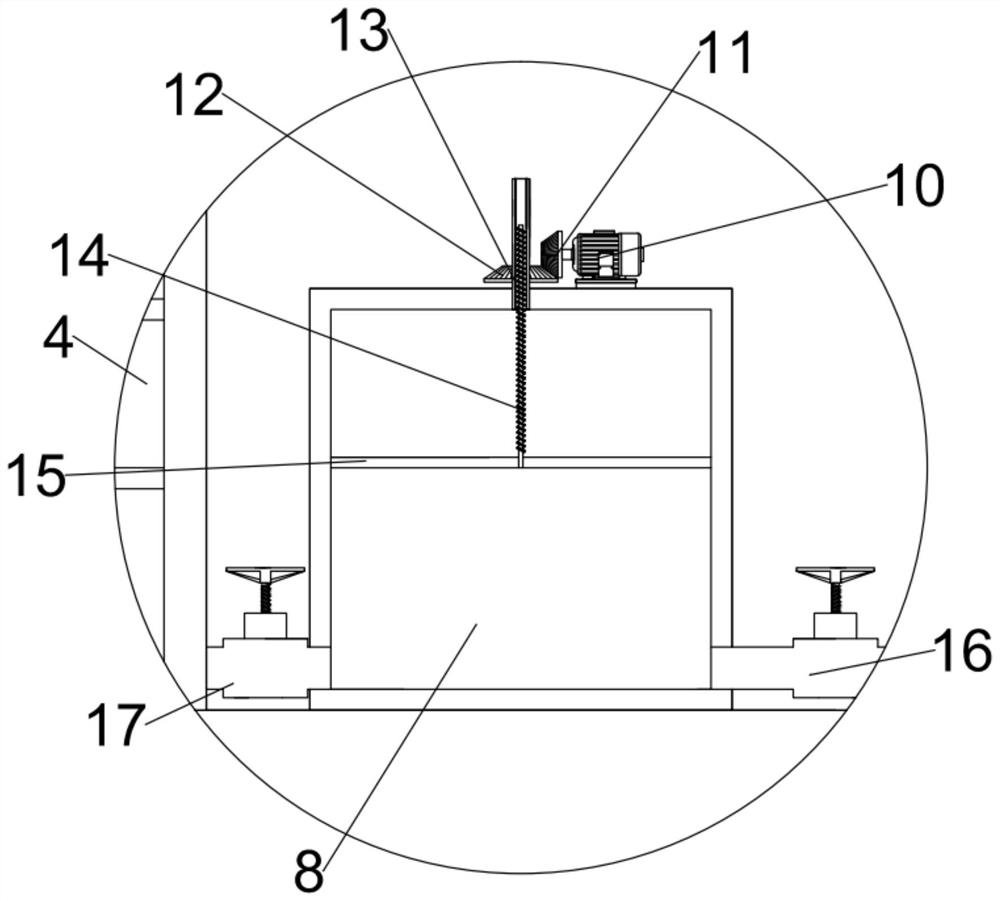

[0050]Embodiment 2: take waste diethylene glycol monobutyl ether and ethanolamine stripping liquid, add the hydrochloric acid solution that volume concentration is 35% wherein, the polarity and the pH value of waste diethylene glycol monobutyl ether and ethanolamine are adjusted, Control the pH value in the range of 6 to 8; and react with impurities such as waste diethylene glycol monobutyl ether and organic bases in ethanolamine to form ethanolamine salt and separate liquid with diethylene glycol monobutyl ether, and step S1 The diethylene glycol monobutyl ether and ethanolamine obtained by tempering are separated to obtain the upper layer diethylene glycol monobutyl ether and the lower layer ethanolamine, and the lower layer ethanolamine obtained by step S2 liquid separation is preheated to 110 ° C, and heated Nitrogen at 110°C, remove residual water and HCl, diethylene glycol monobutyl ether in the upper layer obtained by liquid separation in step S2 and ethanolamine after g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com