Organosilicon special coating

A silicone and special technology, applied in the direction of conductive coatings, coatings, etc., can solve problems affecting construction progress, affecting shielding and conduction, affecting shielding and conduction effects, etc., and achieves the effect of easy cleaning and excellent anti-static function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

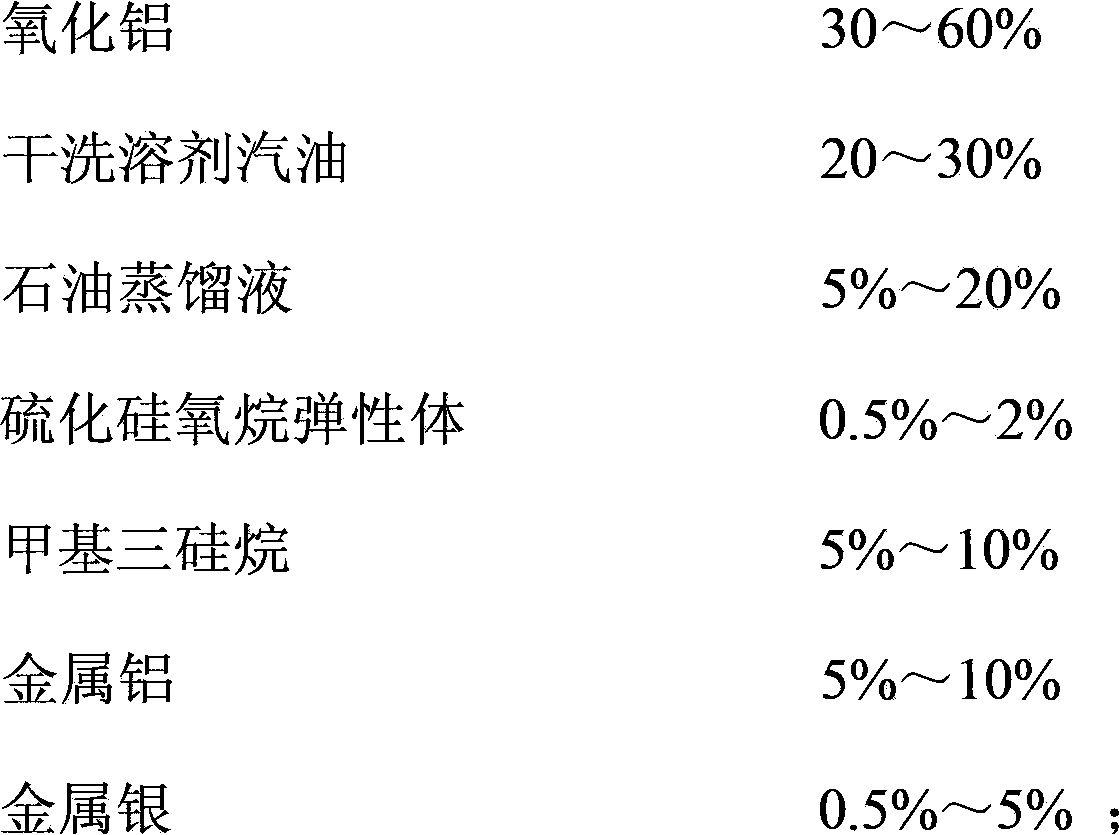

[0018] A kind of organosilicon special paint, by weight percentage, comprises following components:

[0019]

[0020] The above-mentioned raw materials are mixed, ground, toned, and filtered at a temperature above -20°C to obtain the required paint and then packaged.

Embodiment 2

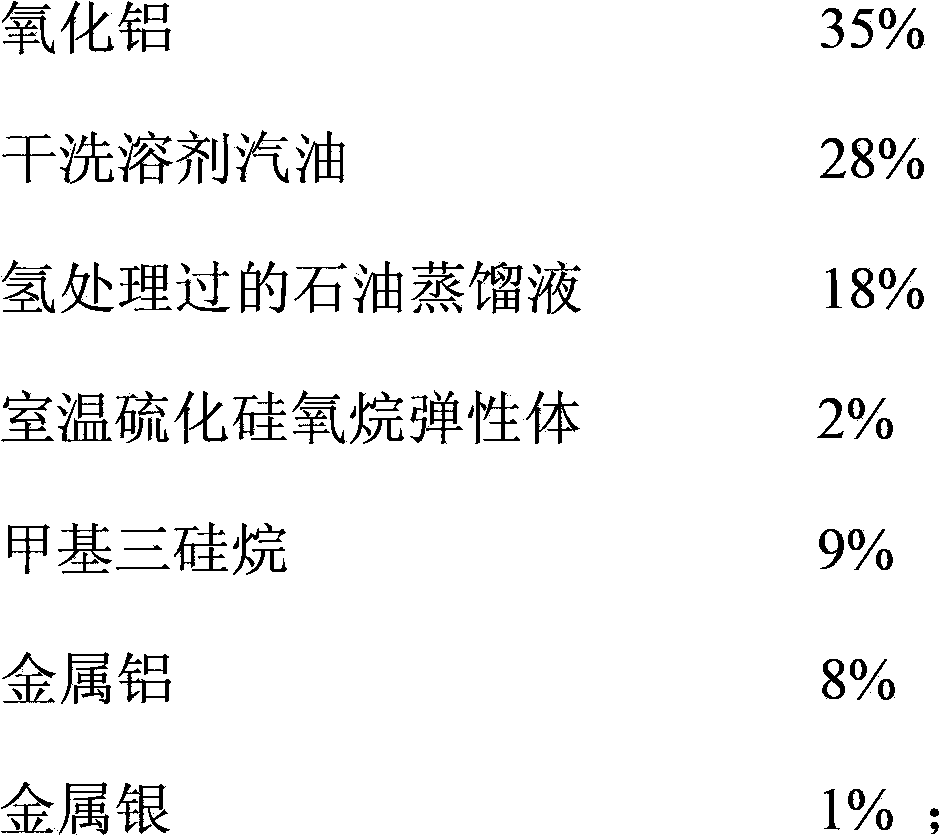

[0022] A kind of organosilicon special paint, by weight percentage, comprises following components:

[0023]

[0024]

[0025] The above-mentioned raw materials are mixed, ground, toned, and filtered at a temperature above -20°C to obtain the required paint and then packaged.

Embodiment 3

[0027] A kind of organosilicon special paint, by weight percentage, comprises following components:

[0028]

[0029] The above-mentioned raw materials are mixed, ground, toned, and filtered at a temperature above -20°C to obtain the required paint and then packaged.

[0030] Technical scheme provided by the present invention is as follows through the inspection report issued by Shanghai Institute of Quality Supervision and Inspection Technology:

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com