Method for recovering and purifying 2-methylpyridine waste liquid

A technology of picoline and a purification method, applied in the field of recovery and purification of 2-picoline waste liquid, can solve the problems of affecting the amount of solution recovery, affecting the drying and use of materials, unfavorable cleaning of drying equipment, etc., so as to facilitate sufficient collection and operation Stable and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

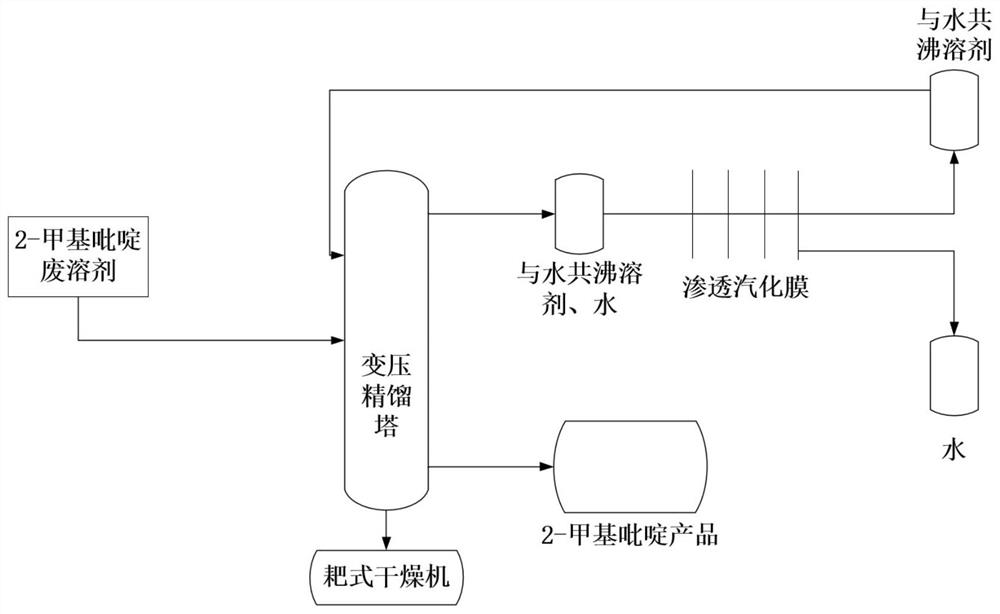

[0039] according to figure 1 , a method for recovering and purifying 2-picoline waste solvent, characterized in that the step of extracting comprises:

[0040] Take the waste solvent containing 55% 2-picoline in 0.5m 3 / h is pumped into the pressure swing rectification column, and the positive pressure rectification obtains the isopropanol-water azeotropic component at the top of the tower. The middle liquid temperature is 99°C, the tank top temperature is 98°C, and the reflux ratio is 15:1.

[0041] The isopropanol-water azeotropic component that above-mentioned rectification obtains is with 1.5m 3 / h steam is passed into the pervaporation membrane, and the dehydrated isopropanol is circulated into the pressure swing rectification column.

[0042] From the side line of the pressure swing rectification tower at 0.20m 3 2-methylpyridine is mined in / h; industrial-grade 2-picoline with a purity of ≥99.9% (wt) is obtained.

[0043] Distillation tower kettle material accordin...

Embodiment 2

[0045] Based on embodiment 1, a kind of recovery and purification method of 2-picoline waste solvent is characterized in that, the extraction step comprises:

[0046] Take 60% 2-picoline waste solvent with 0.6m 3 / h is pumped into the pressure swing rectification column, and the positive pressure rectification obtains the isopropanol-water azeotropic component at the top of the tower. The middle liquid temperature is 118°C, the tank top temperature is 117°C, and the reflux ratio is 20:1.

[0047] The isopropanol-water azeotropic component that above-mentioned rectification obtains is with 1m 3 / h steam is passed into the pervaporation membrane, and the dehydrated isopropanol is circulated into the pressure swing rectification column.

[0048] From the side line of the pressure swing rectification tower at 0.29m 3 2-methylpyridine is mined in / h; industrial-grade 2-picoline with a purity of ≥99.9% (wt) is obtained.

[0049] Distillation tower kettle material according to 0.19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com