Method for recovering tetrahydrofuran from waste solvent

A technology for tetrahydrofuran and waste solvents, which is applied in the field of purification and recovery of tetrahydrofuran and recovery of tetrahydrofuran in waste solvents, can solve the problems of complex process and high cost, achieve good purity, low price, and reduce the harm to human body and environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

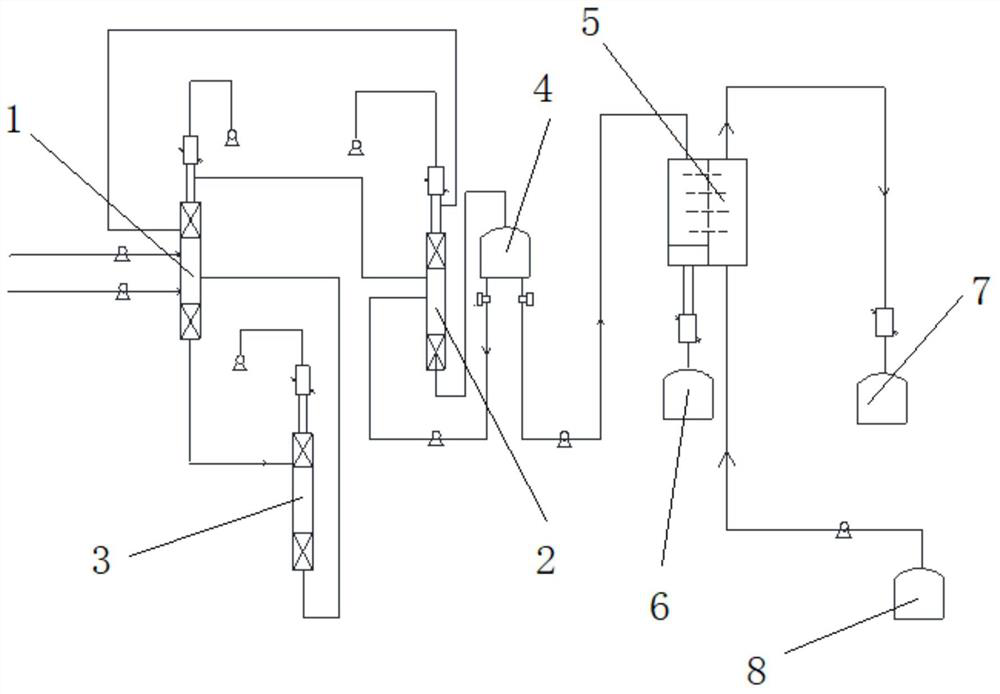

Image

Examples

preparation example Construction

[0032] The preparation method of described hydrophilic polyaniline pervaporation membrane is:

[0033]Add deionized water to the reactor, then add aniline with 10% to 15% deionized water quality into the reactor, stir continuously, then mix sulfuric acid and sulfosalicylic acid in a molar ratio of 1:4 to obtain a mixed acid, Add excess mixed acid to the reaction kettle, aniline reacts with acid to generate soluble sulfate, and add ammonium persulfate 1.5 times the quality of aniline dropwise to the generated sulfate solution at a rate of 5mL / min under constant stirring solution, after adding ammonium persulfate, the color of the solution gradually changes from light yellow to green, and as the reaction continues, the color of the solution gradually deepens and finally turns emerald green. Control the reaction temperature at 20°C for polymerization for 6 hours. Filter, and successively wash and filter with compound acid, absolute ethanol, and distilled water until the filtrate ...

Embodiment 1

[0039] The feed flow rate of tetrahydrofuran-methanol-water mixed liquid is 1000kg / h, and the mass composition is: tetrahydrofuran 70%, methanol 25%, water 5%. The solution is preheated to 60°C by a heater, and then added to an atmospheric rectification column for extraction and rectification. Ethylene glycol was added as an extractant. The feed ratio of the extractant to the tetrahydrofuran-methanol-water mixture was 1.5:1, the reflux ratio was controlled to be 6, the heating temperature of the tower bottom was 75°C, and the temperature at the top of the tower was 64.7°C. The number of trays in the atmospheric rectification column is 55, and the number of trays in the high-pressure rectification column is 38. The extraction agent is ethylene glycol. For ethylene glycol, methanol and water. The ethylene glycol at the bottom of the tower is sent to the separation tower for separation, and the ethylene glycol is recycled. Send the azeotrope discharged from the top of the towe...

Embodiment 2

[0041] The feed flow rate of tetrahydrofuran-methanol-water mixture is 1200kg / h, preheated to 60°C by a heater, and its mass composition is: 50% tetrahydrofuran, 40% methanol, and 10% water. The feed ratio of extractant to tetrahydrofuran-methanol-water mixture is 2:1, rectification at atmospheric pressure, the control reflux ratio is 6, the number of trays in the rectification column at atmospheric pressure is 55, and the number of trays in the high-pressure rectification column is 38 blocks, the heating temperature of the tower bottom is 78°C, the temperature at the top of the tower is 63.4°C, the extraction agent is ethylene glycol, the top discharge is an azeotrope containing a large amount of tetrahydrofuran and a small amount of methanol, and the bottom discharge is ethylene glycol, methanol and water. The ethylene glycol at the bottom of the tower is sent to the separation tower for separation, and the ethylene glycol is recycled. The azeotrope discharged from the top ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com