Shoe polyurethane adhesive prepared from recycled solvent and processing method

A technology for polyurethane adhesives and solvent recovery, applied in the direction of polyurea/polyurethane adhesives, adhesive types, adhesives, etc., can solve the problems of reducing production costs, increasing production costs, and difficult disposal of waste solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

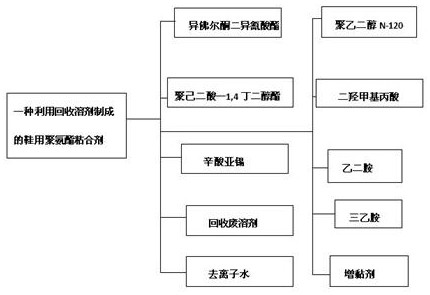

[0009] figure 1 As shown in , a polyurethane adhesive for shoes made from recycled solvents, including the following components: isophorone diisocyanate (IPDI, industrial product), polyadipate-1,4-butylene glycol ester ( Industrial product), polyethylene glycol N-120 (molecular weight 1000, imported), dimethylolpropionic acid (industrial product), stannous octoate (analytical pure), recovered waste solvent (about 30% water content), deionized water , ethylenediamine (analytical pure), triethylamine (analytical pure), tackifier; said isophorone diisocyanate, polyadipate-1,4-butylene glycol ester, polyethylene glycol N-120 , dimethylolpropionic acid, stannous octoate, recovered waste solvent, deionized water, ethylenediamine, and triethylamine in the following proportions: isophorone diisocyanate 13.2g, polyadipate-1,4 butanedi Alcohol ester 100g, polyethylene glycol N-120 2.7g, dimethylolpropionic acid 4.3g, stannous octoate 0.5g, recovered waste solvent 350ml, deionized water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com