A kind of asphalt concrete pavement protective agent and its preparation method and application

An asphalt concrete and protective agent technology, applied in asphalt coatings, coatings, etc., can solve the problems of difficult to achieve the protective function of asphalt concrete pavement, affect the service life of asphalt concrete, etc. Strong penetration and filling repair ability, the effect of prolonging the life of the pavement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

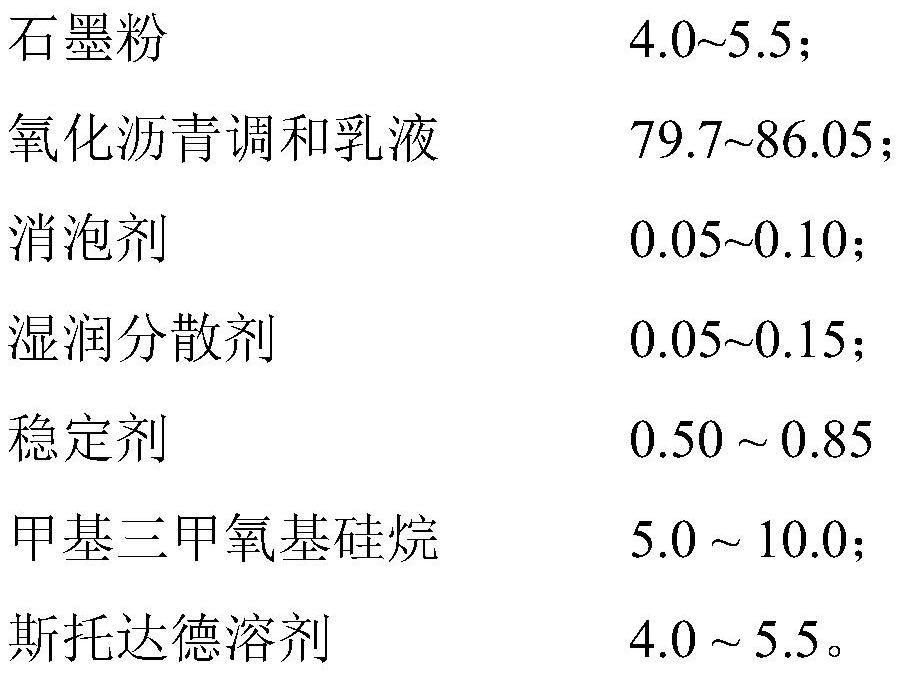

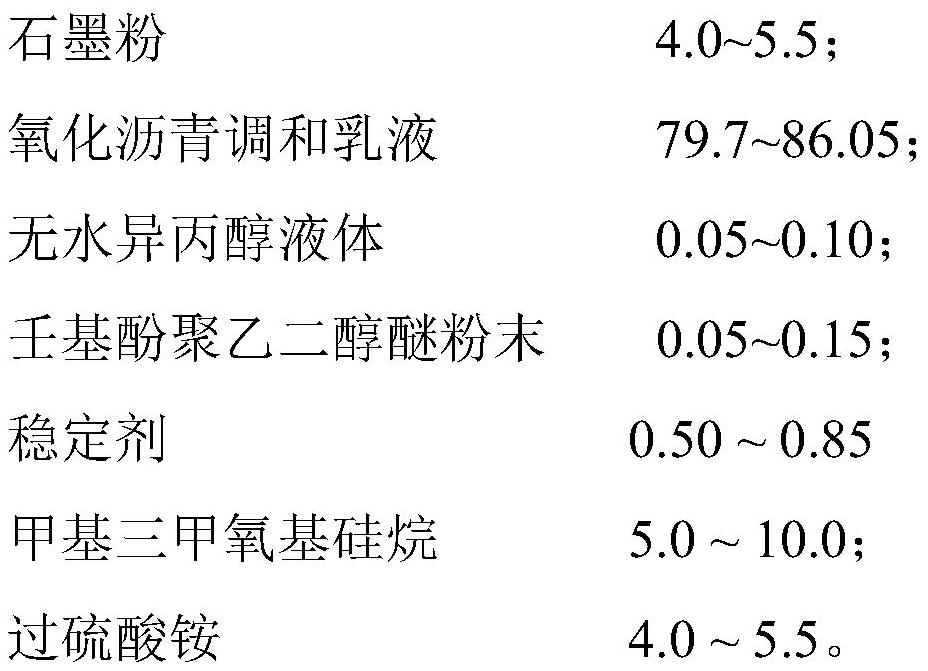

[0035] An asphalt concrete pavement protective agent, comprising the following components in weight percentage: graphite powder: 4.0%, oxidized asphalt blending emulsion: 86.05%, anhydrous isopropanol: 0.05%, nonylphenol polyethylene glycol ether: 0.05% , ammonium persulfate: 0.85%, methyltrimethoxysilane: 5.0%, Stoddard solvent 4.0%: 100kg sample was prepared for trial mixing.

[0036] The first step, weigh 86.05kg of oxidized asphalt blending emulsion and place it in the reactor, stir at low speed (25rpm), add graphite powder slowly, the amount of one time mixing can not exceed the total amount of 0.8kg, gradually increase the stirring speed to 1500rpm, stir for 10 Minutes, the graphite powder is evenly dispersed in the emulsion, then slowly add the graphite powder, continue to stir for 10 minutes, repeat the above process until all the graphite powder is evenly dispersed in the emulsion. Put the uniformly dispersed emulsion in a sealed container and let it cool for 24 hours...

Embodiment 2

[0041] An asphalt concrete pavement protective agent, comprising the following components in weight percentage: graphite powder: 5.0%, oxidized asphalt blending emulsion: 81.82%, anhydrous isopropanol: 0.08%, nonylphenol polyethylene glycol ether: 0.10% , ammonium persulfate: 0.50%, methyltrimethoxysilane: 8.0%, Stoddard solvent 4.5%: 100kg sample was prepared for trial mixing.

[0042] The first step, weigh 81.82kg of oxidized asphalt blend emulsion and place it in the reactor, stir at low speed (25rpm), slowly add graphite powder, the amount of one-time mixing should not exceed the total amount of 1.0kg, gradually increase the stirring speed to 1500rpm, stir for 10 Minutes, the graphite powder is evenly dispersed in the emulsion, then slowly add the graphite powder, continue to stir for 10 minutes, repeat the above process until all the graphite powder is evenly dispersed in the emulsion. Place the uniformly dispersed emulsion in a sealed container and let it cool for 24 hou...

Embodiment 3

[0047] An asphalt concrete pavement protective agent, comprising the following components in weight percentage: graphite powder: 4.5%, oxidized asphalt blending emulsion: 79.7%, anhydrous isopropanol: 0.10%, nonylphenol polyethylene glycol ether: 0.15% , ammonium persulfate: 0.55%, methyltrimethoxysilane: 10.0%, Stoddard solvent 5.0%: 100kg sample was prepared for trial mixing.

[0048] The first step, weigh 79.7kg of oxidized pitch blending emulsion and place it in the reactor, stir at a low speed (25rpm), slowly add graphite powder, the amount of one-time mixing cannot exceed the total amount of 0.9kg, gradually increase the stirring speed to 1500rpm, and stir for 10 Minutes, the graphite powder is evenly dispersed in the emulsion, then slowly add the graphite powder, continue to stir for 10 minutes, repeat the above process until all the graphite powder is evenly dispersed in the emulsion. Place the uniformly dispersed emulsion in a sealed container and let it cool for 24 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com